LED constant-flow driver

A constant current driver and current sampling technology, which is applied in the field of power circuits, can solve problems such as large heat generation, unadjustable frequency, and limited voltage division effect of current-limiting resistors, so as to prolong service life, reduce product cost, and consume less power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

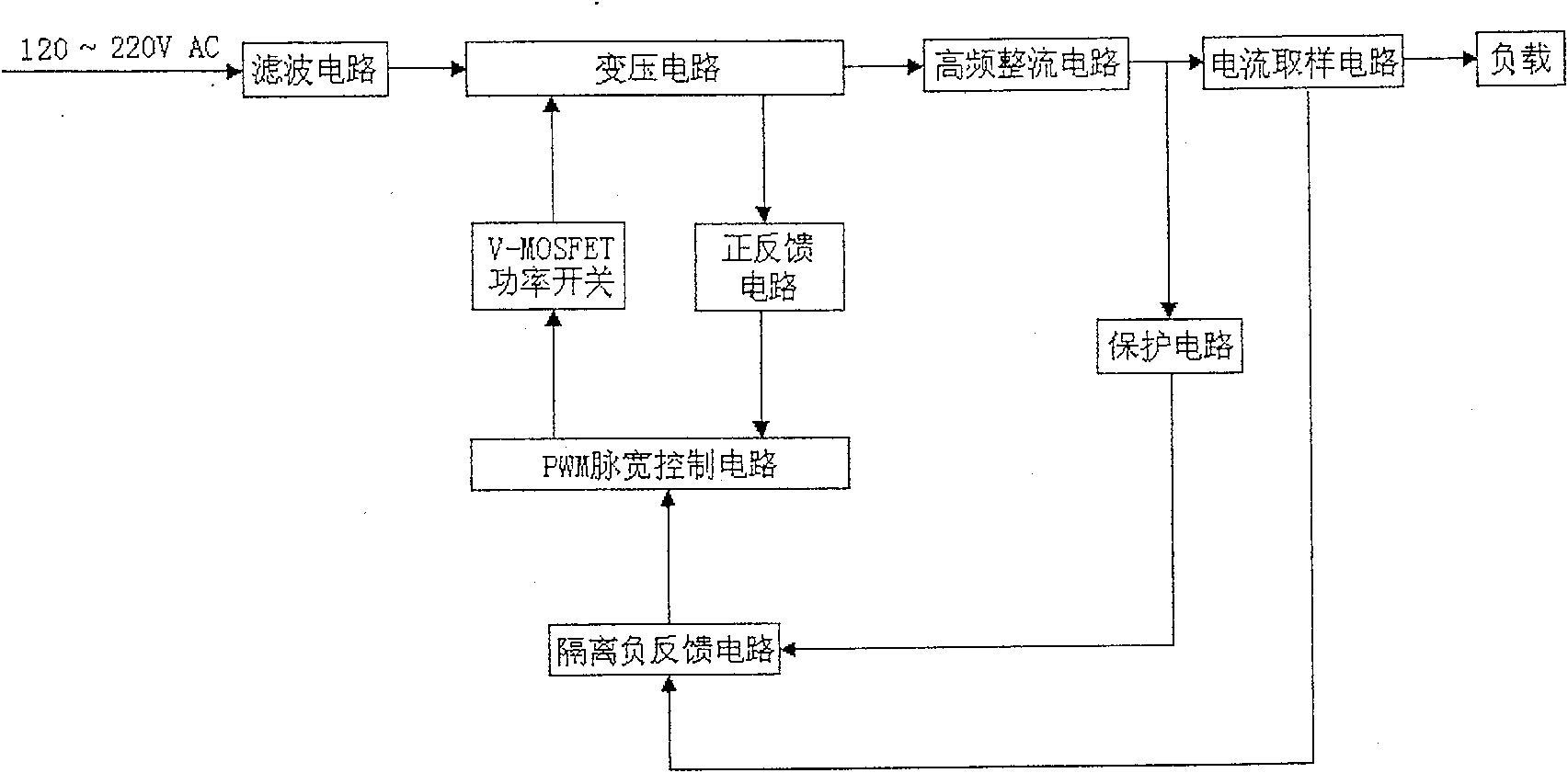

[0018] An LED constant current driver includes a filter circuit, a voltage transformer circuit, a high-frequency rectification filter circuit, a current sampling circuit, a protection circuit, an isolated negative feedback circuit, a positive feedback circuit, a PWM pulse width control circuit and a V-MOSFET power switch. The filter circuit includes an EMI filter and a rectifier filter, and the current limiting resistor R is passed between the EMI filter and the rectifier filter. 1 and negative temperature thermistor R 2 connect.

[0019] The current limiting resistor R in the filter circuit 1 The function is to fuse quickly when the latter stage is over-current, so as to prevent the driver from burning out.

[0020] Negative Temperature Thermistor R 2 The function is that when the ambient temperature rises, the resistance value rises, so that the output current amplitude of the driver decreases, and the power consumption of the load and the driver decreases.

[0021] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com