High-power light-emitting diode lamp

A light-emitting diode, high-power technology, which is applied to the semiconductor devices, optics, light guides and other directions of light-emitting elements, can solve the problems of reduced effective light utilization rate, insufficient lighting angle, and inability of high-power LED lamps 148 to achieve good light concentration. effect, increase lighting brightness, increase lighting angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

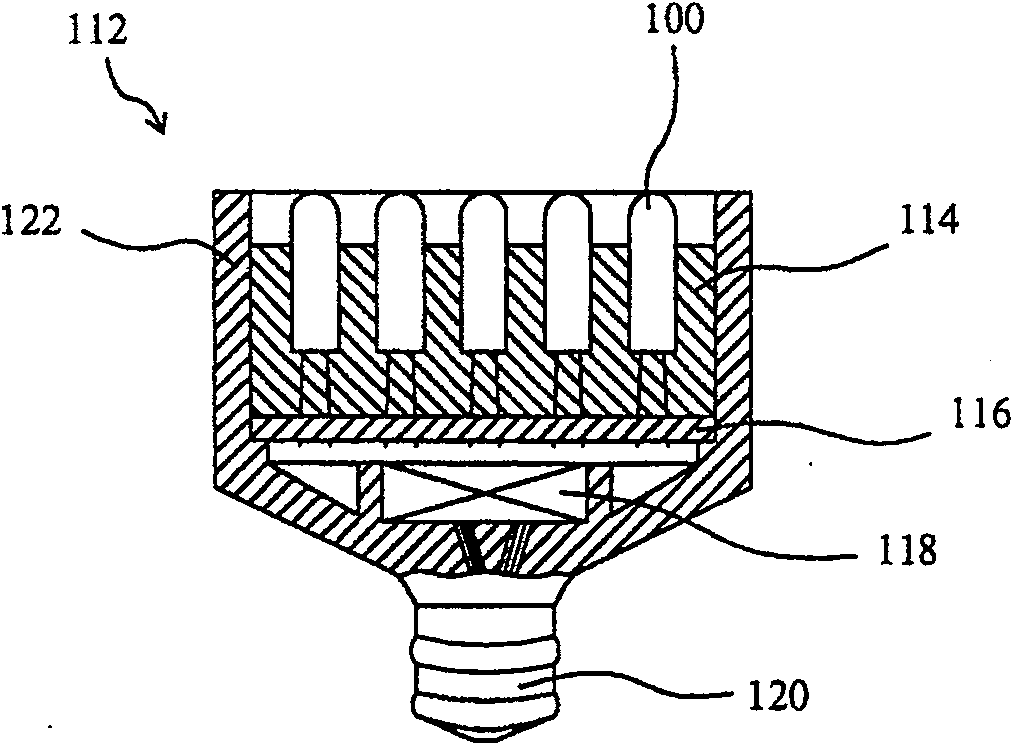

[0073] Figure 13 A high power LED electric lamp 200 of the present invention is shown, Figure 14 for its exploded view. In the high-power LED lamp 200, the lampshade 202 has a chamber 203, which is filled with a light-transmitting liquid 204; On the MCPCB 210, the packaging adhesive layer 208 fixes the high-power LED 206 and the MCPCB 210 in a carrier 212 and forms a watertight structure; one end of the carrier 212 is placed in the positioning ring 214 and the sealing cover 216; the sealing adhesive layer 218 is placed on the Seal cap 216 seals the nozzle of lampshade 202; and a power conversion drive module 220 is connected between this high-power LED light source device and a bulb standard connector 224, thus, the power that introduces from power line 226 is converted into direct current constant current , to drive the high power LED 206 via the power line 222 . The profile of sealing cover 216 is as Figure 15 As shown, it has an inclined surface 232 and a groove 234 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com