Oil pumping workover rig

A workover rig and oil pumping technology, applied to drilling equipment, wellbore/well components, drill pipes, etc., can solve the problems of reduced service life and performance of equipment, insufficient traction, difficult workover, etc., to achieve workover function Integrity, prolonging service life and convenient workover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

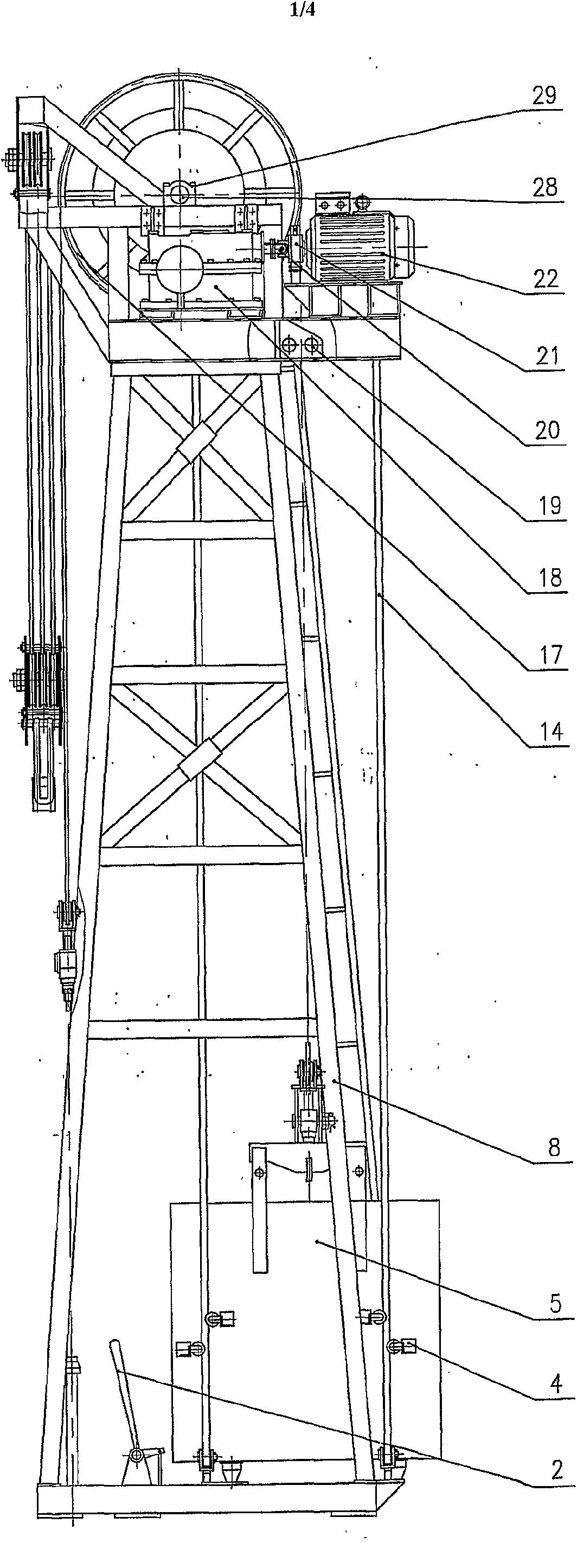

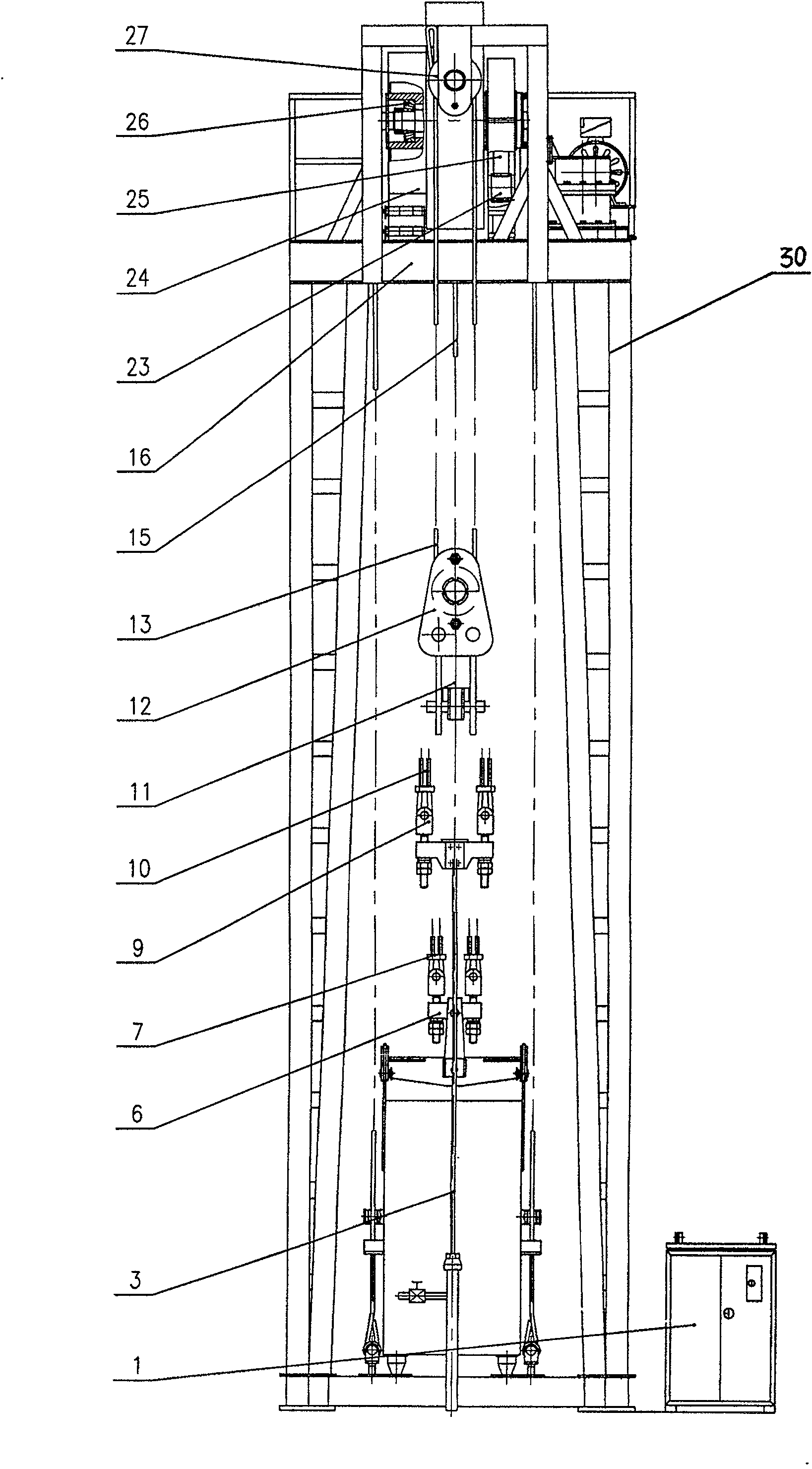

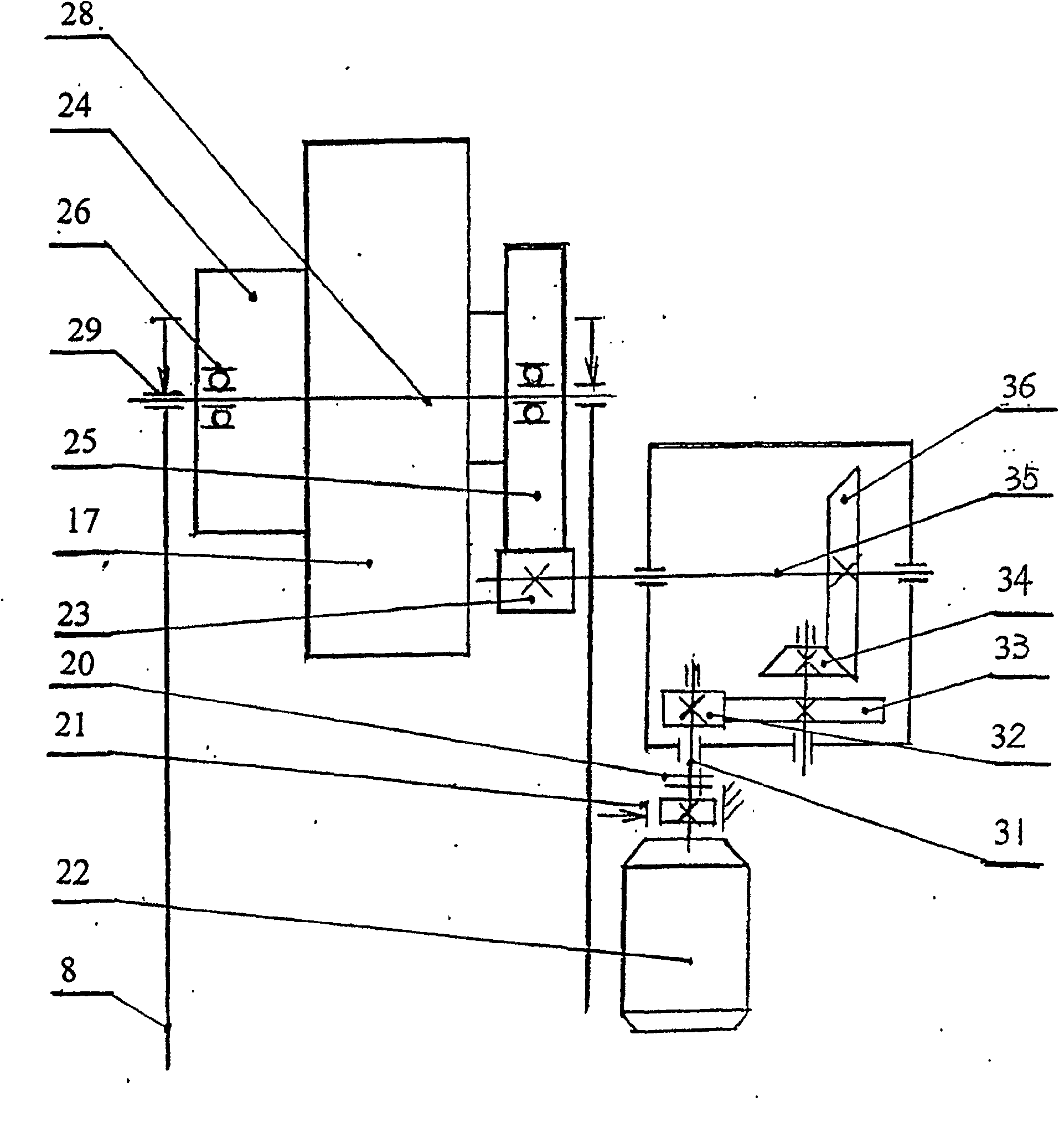

[0013] refer to figure 1 , figure 2 , the present invention includes an electric control cabinet 1, a main frame 8, a support platform 16, a motor 22, an electric brake 21, a coupling 20, a reducer 18, a polished oil rod 3, a rope suspension device 9 for a polished oil rod, and a sucker rod rope 10. Counterweight box 5, counterweight rope hanger 6, counterweight rope 7, protection rope 15, protection rope clamp 19, driving device, bracket platform 16 is located on the main frame 8, and motor 22 passes through electric brake 21 and joint The shaft device 20 is in drive connection with the reducer 18, the reducer 18 is connected to the driving device, one end of the sucker rod rope 10 is connected to the oil sucking rod 3 through the oil sucking rod hanging device 9, and the other end is fixed on the driving device, and one end of the counterweight rope 7 is Connect the counterweight rope hanger 6 on the counterweight box 5, and the other end is fixed on the driving device, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com