Dress ornament non-ironing drying shaper

A technology of setting machine and clothing, which is applied in the field of clothing production equipment and clothing non-ironing drying and setting machines, can solve the problems of high working environment temperature, low production efficiency, and large energy consumption, and achieve high production efficiency, energy saving, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

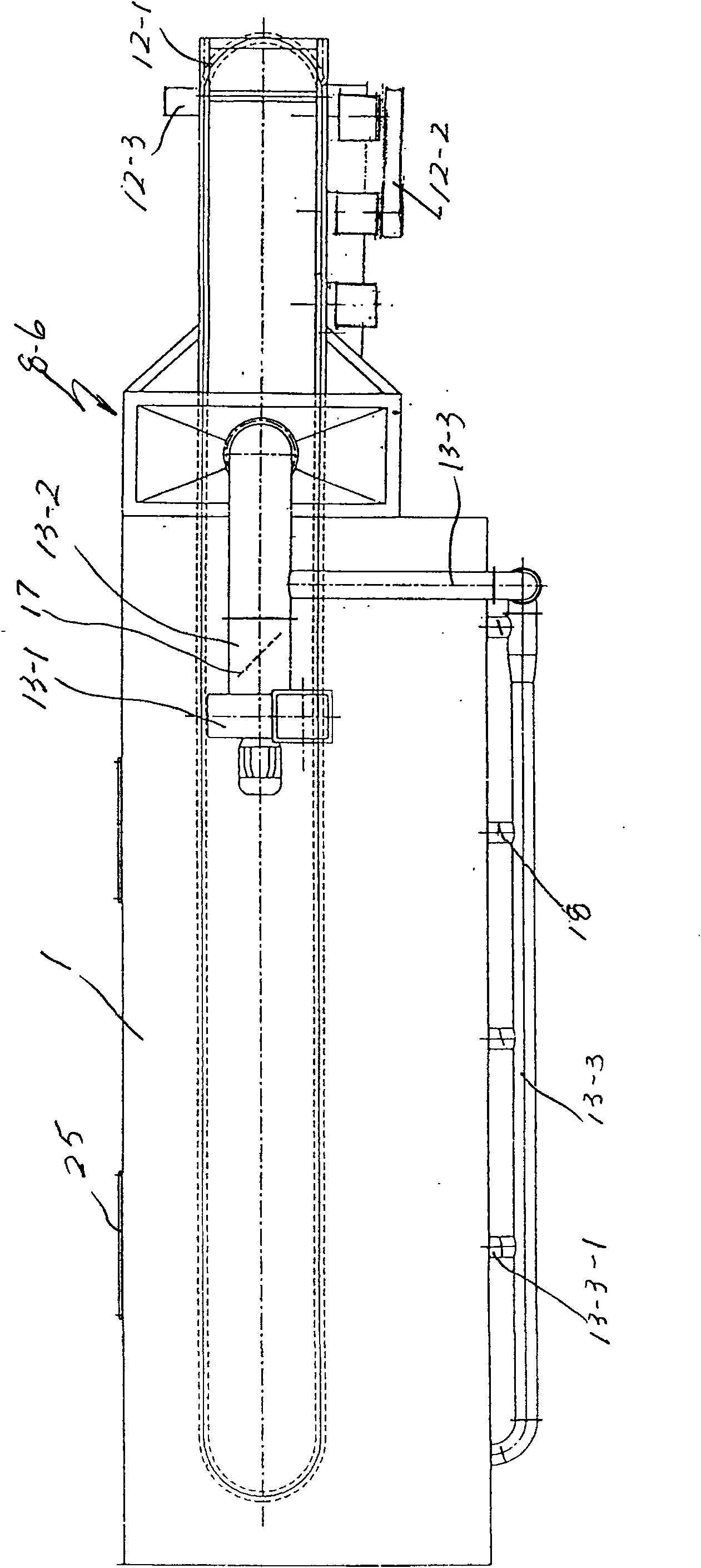

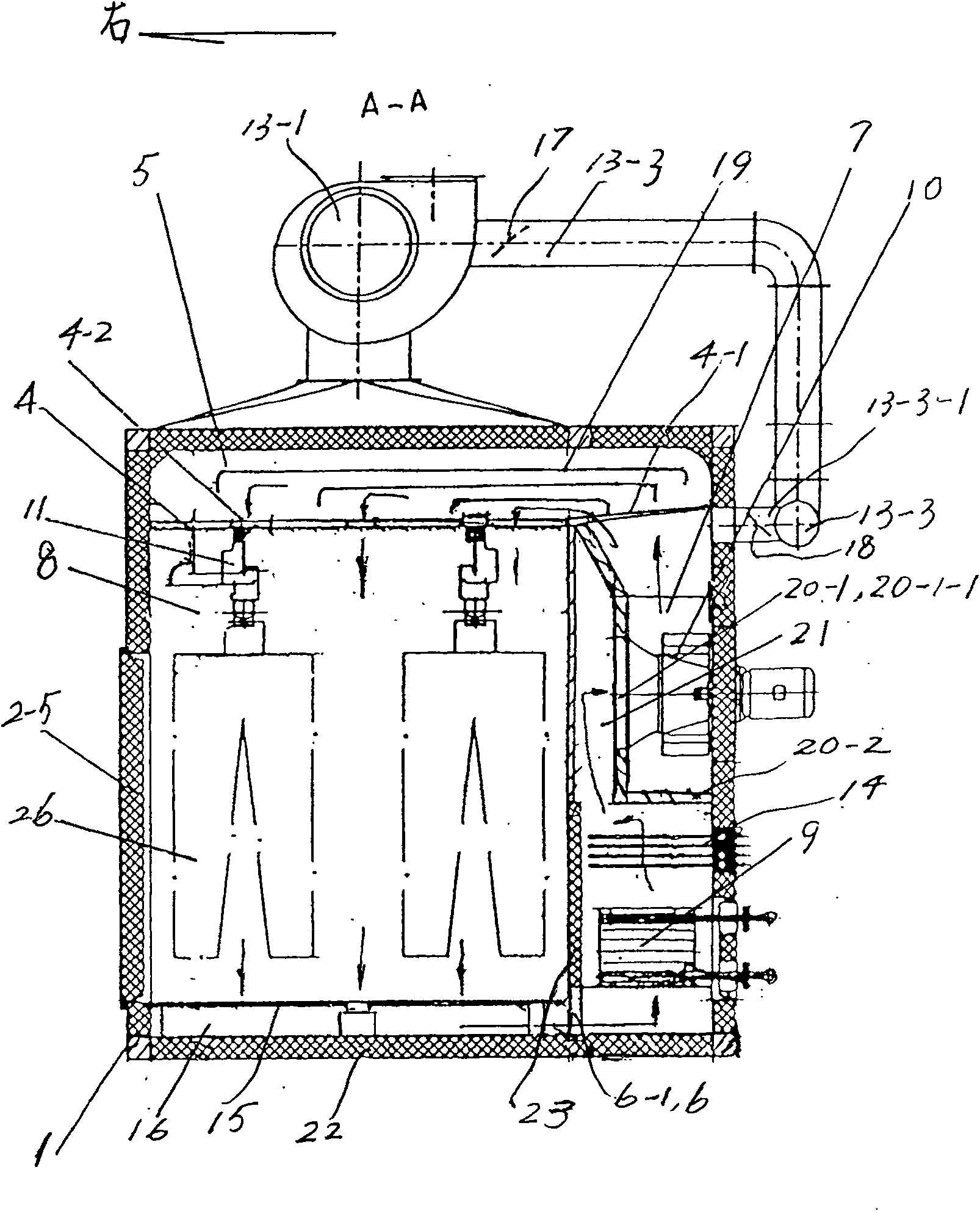

[0035] A typical embodiment of the present invention, as attached Figures 1 to 8 shown.

[0036]A non-ironing drying and setting machine for clothing, comprising a box body 1 and an electric control device 2, one end of the box body 1 is open; the working area 8 of the box body 1 is divided into sections for entering and exiting workpieces along the length direction 8-6 and 5 working sections 8-1, 8-2, 8-3, 8-4, 8-5, which are arranged separately but connected to each other, working sections 8-1, 8-2, 8 -3, 8-4, and 8-5 are respectively provided with temperature sensors 3; in the upper part of the box body 1, there are air inlets 4-1 and several air outlets 4-2 on both sides. plate 4, and the air plate 4 is fixedly connected to the box body 1 through the crossbeam 24, which is corresponding to the working sections 8-1, 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com