Fermentor for applying CO2 fertilizer in greenhouse

A technology of carbon dioxide and fermentation equipment, which is applied in the direction of carbon dioxide production of fertilizers, fertilization equipment, and preparation of organic fertilizers. It can solve problems such as escape and crop poisoning, and achieve the effects of easy installation, prevention of poisoning, and reduction of trace harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

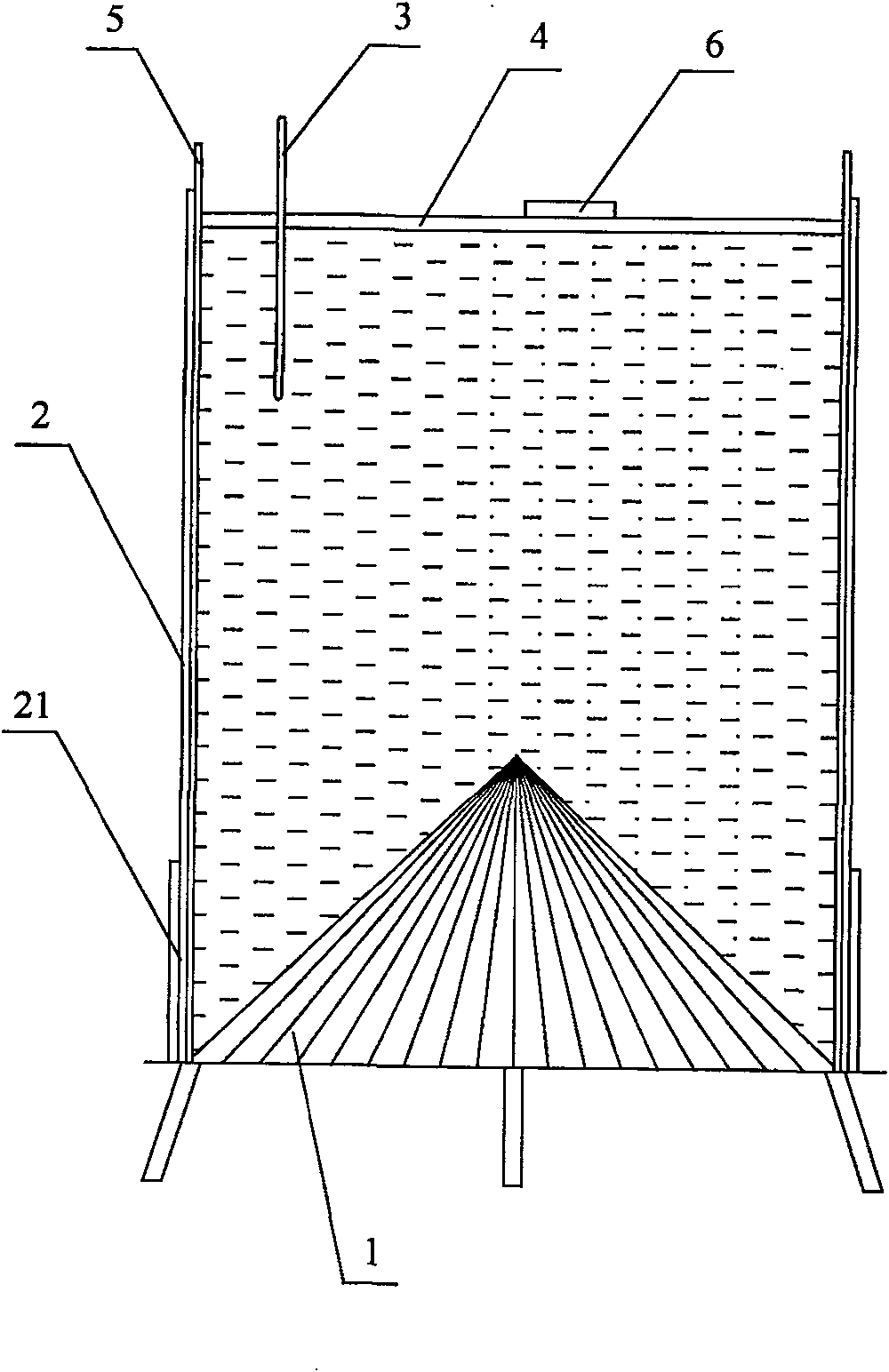

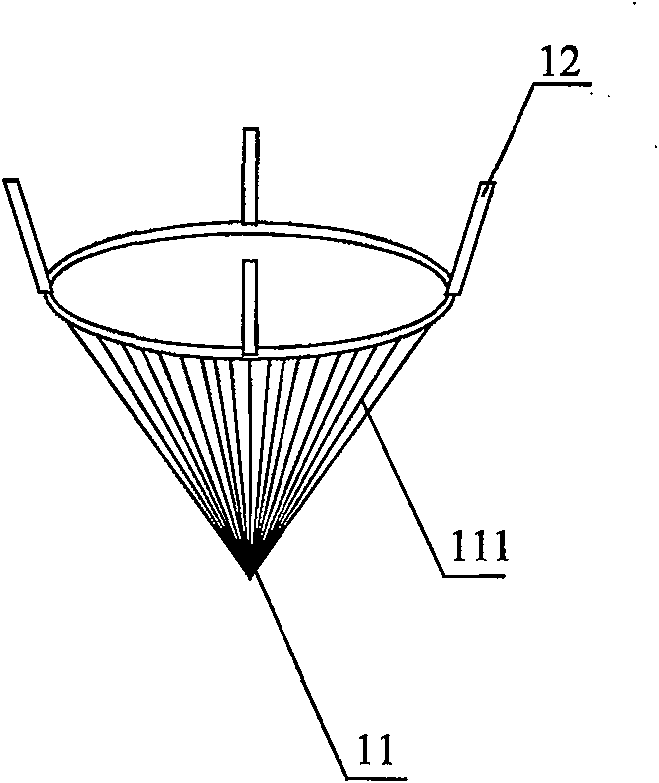

[0024] Figure 1 ~ Figure 3 Combined with a fermentation device for carbon dioxide fertilization in greenhouses, it includes a base assembly 1, the base assembly 1 is composed of an umbrella grid 11 and 4 supports 12, and the 4 supports 12 are evenly and symmetrically arranged on the umbrella grid 11 the lower end. The umbrella-shaped grid 11 is composed of several grid bars 111 and is shaped like an umbrella surface, so the circular bottom of the umbrella-shaped grid 11 is hollow. The grid bar 111 can be made of materials such as steel bars, wooden bars and bamboo poles. The gap between two adjacent grid bars 111 is 8-10 cm, and the gap refers to the largest gap between the two grid bars 111 . In actual use, the diameter of the bottom of the umbrella grid 11 is adjusted accordingly according to the area of the greenhouse and the number of fermentation devices placed in the greenhouse.

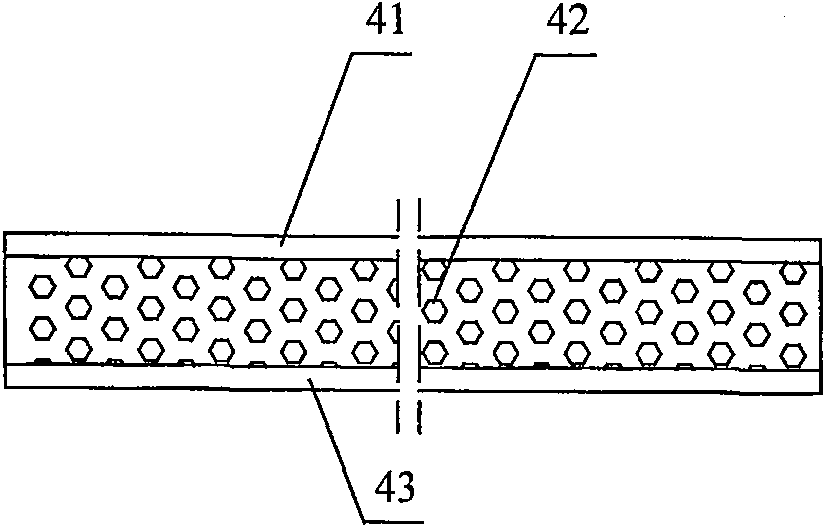

[0025] The barrel body 2 is a tubular thing surrounded by a grid wire mesh sheet. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com