Quantitative dispenser for powder

A powder and powder feeding technology, which is applied in the distribution and packaging of powdery materials, can solve the problems of powder leakage in the slide hopper, hinder the movement of the slide hopper, and the function cannot be realized, and achieve the effect of reducing the gap and lowering the precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

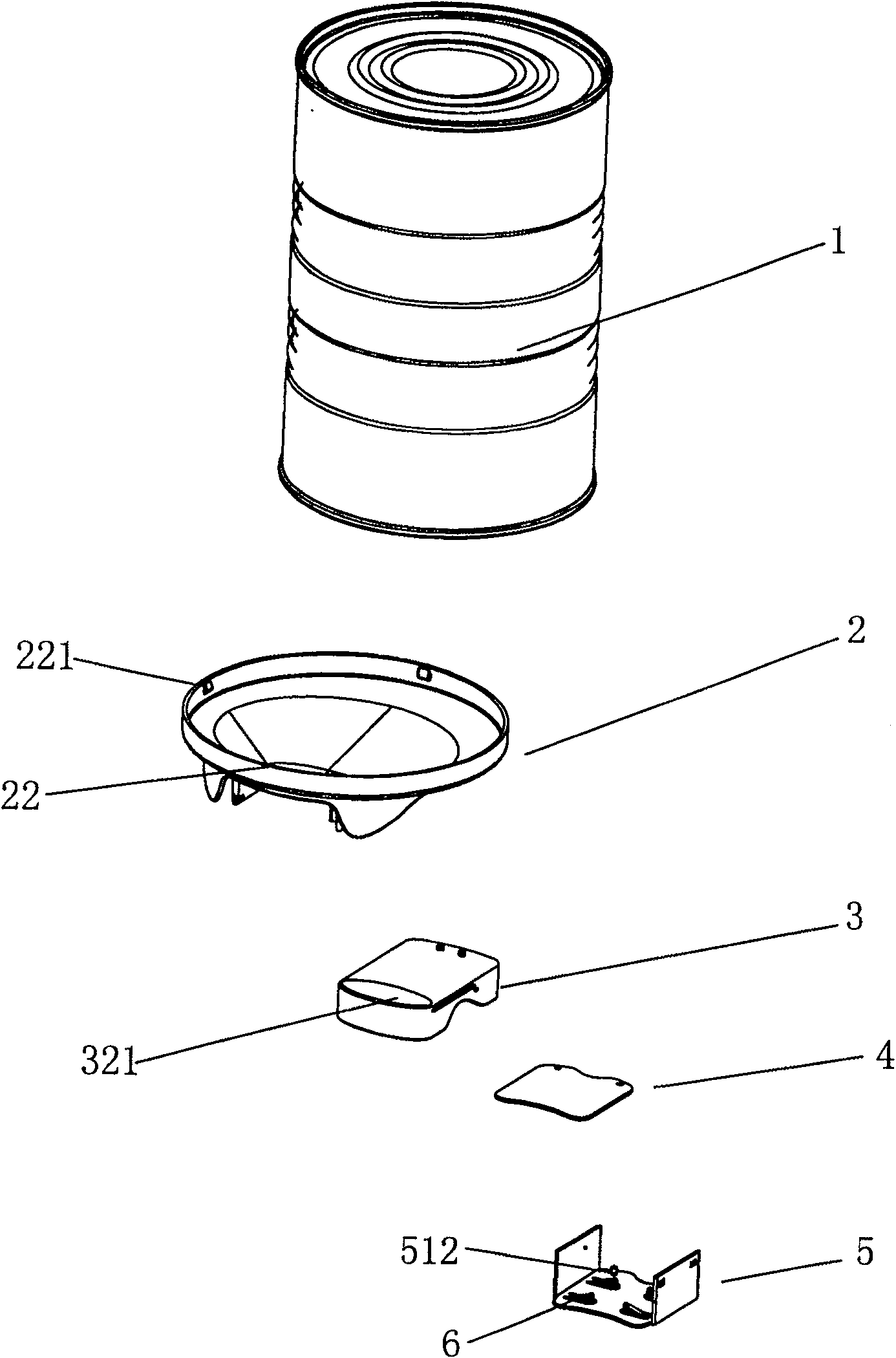

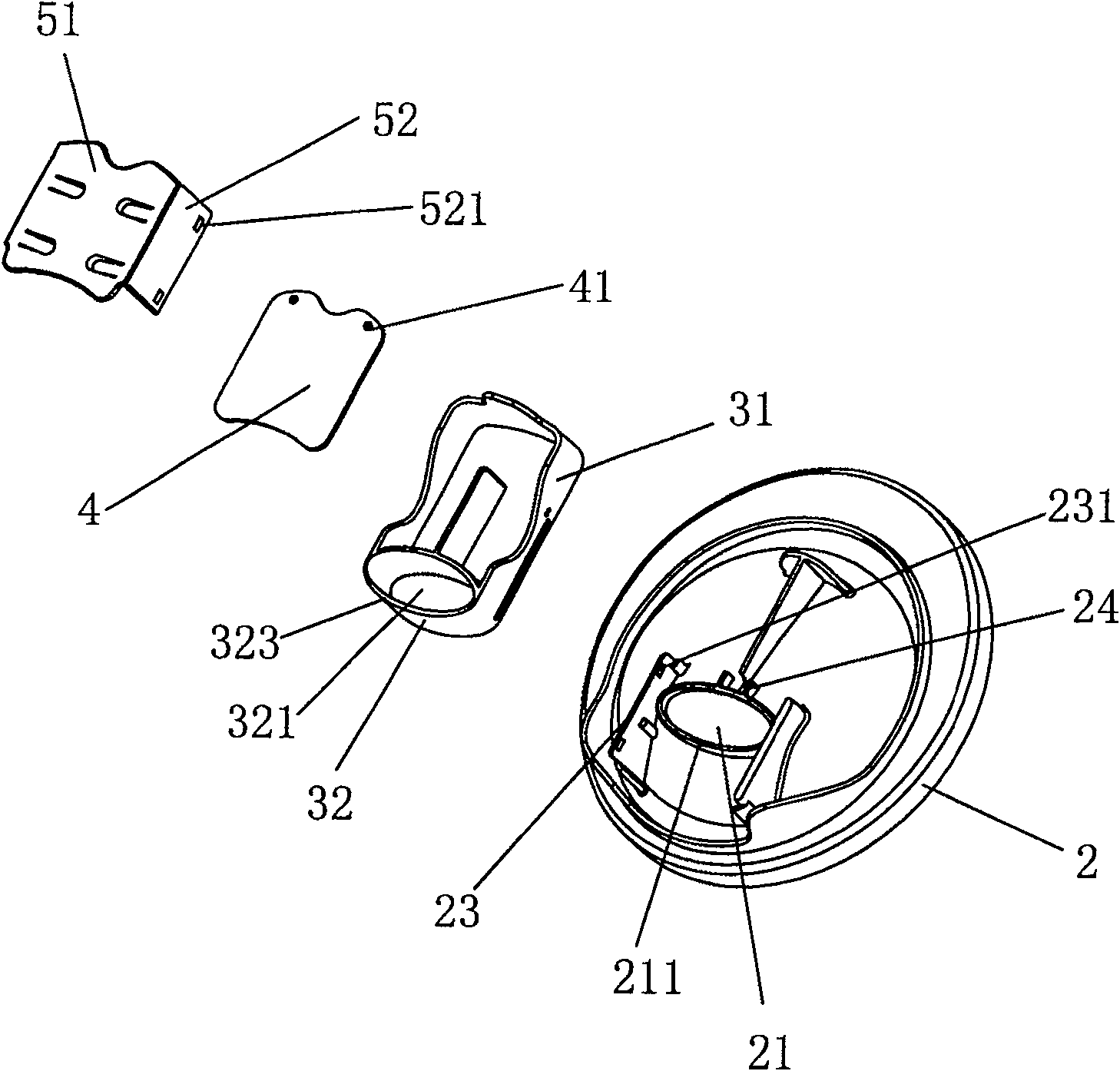

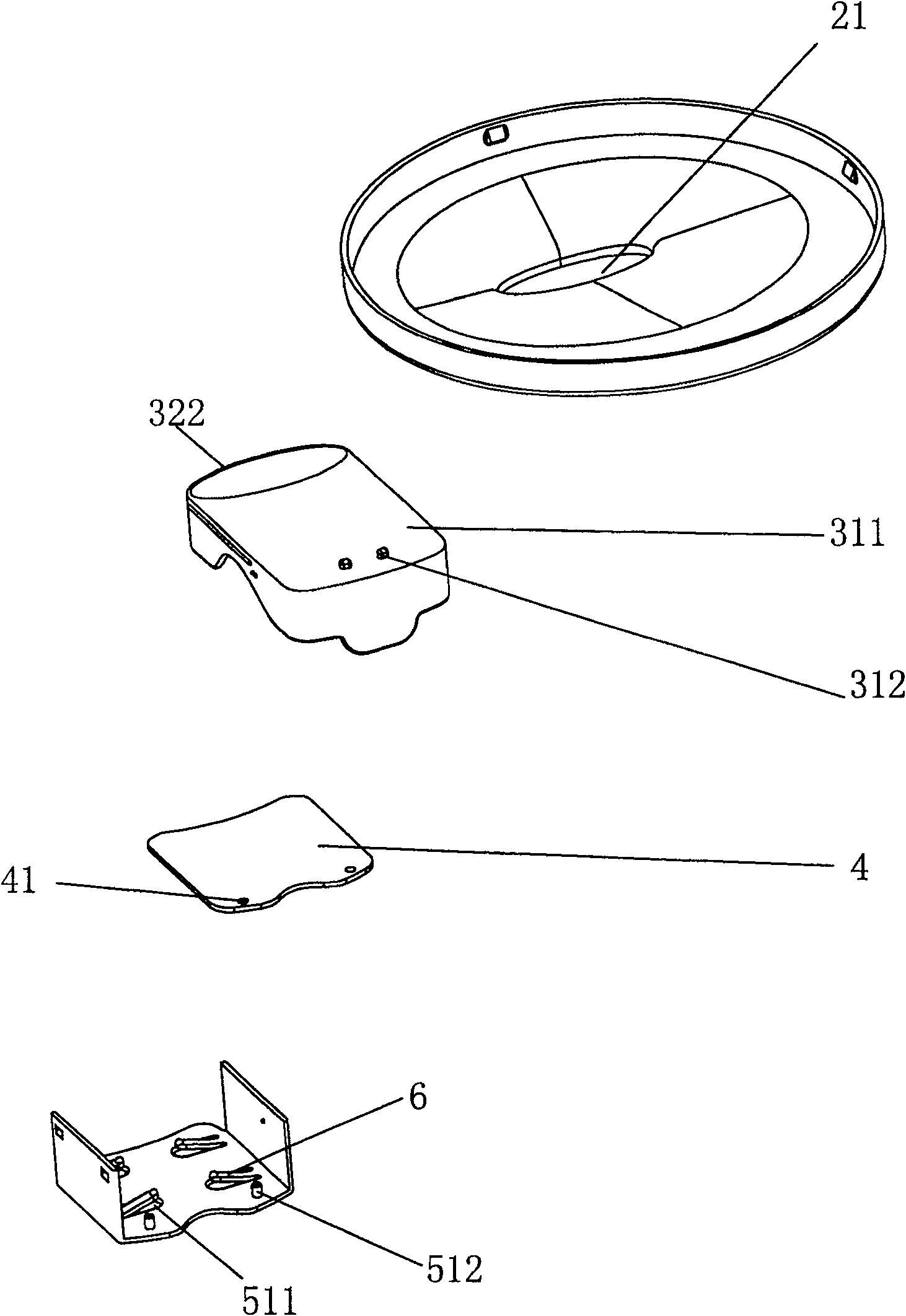

[0058] see Figure 1 to Figure 7 , The powder quantitative taking device of the present invention includes a powder container 1 , a sliding sleeve 2 , a sliding bucket 3 , a cover plate 4 , a pressing plate 5 and an elastic member 6 . The powder container 1 is used for storing powder, and its bottom end is provided with an opening for the powder to fall out. The sliding sleeve 2 is provided with a powder inlet groove 21 , and the powder inlet groove 21 runs through the sliding sleeve 2 along the direction of gravity. The sliding sleeve is provided with a circular fitting wall 22 on the side of the entrance of the powder inlet groove 21, the inner ring of the fitting wall 22 matches the outer ring at the bottom of the powder container 1, and the inner ring is protrudingly provided with a buckle 221, the bottom of the powder container 1 is provided with a slot corresponding to the position of the buckle. The sliding sleeve 2 is provided with two parallel guide rails 23 on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com