Method and equipment for solid-liquid separation

A solid-liquid separation and equipment technology, which is applied in the field of solid-liquid separation, can solve the problems that affect the improvement of the filter cake degree of the belt filter press, reduce the filtration efficiency, and the wear of the filter belt, so as to improve the pressing dehydration efficiency and high dehydration efficiency , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

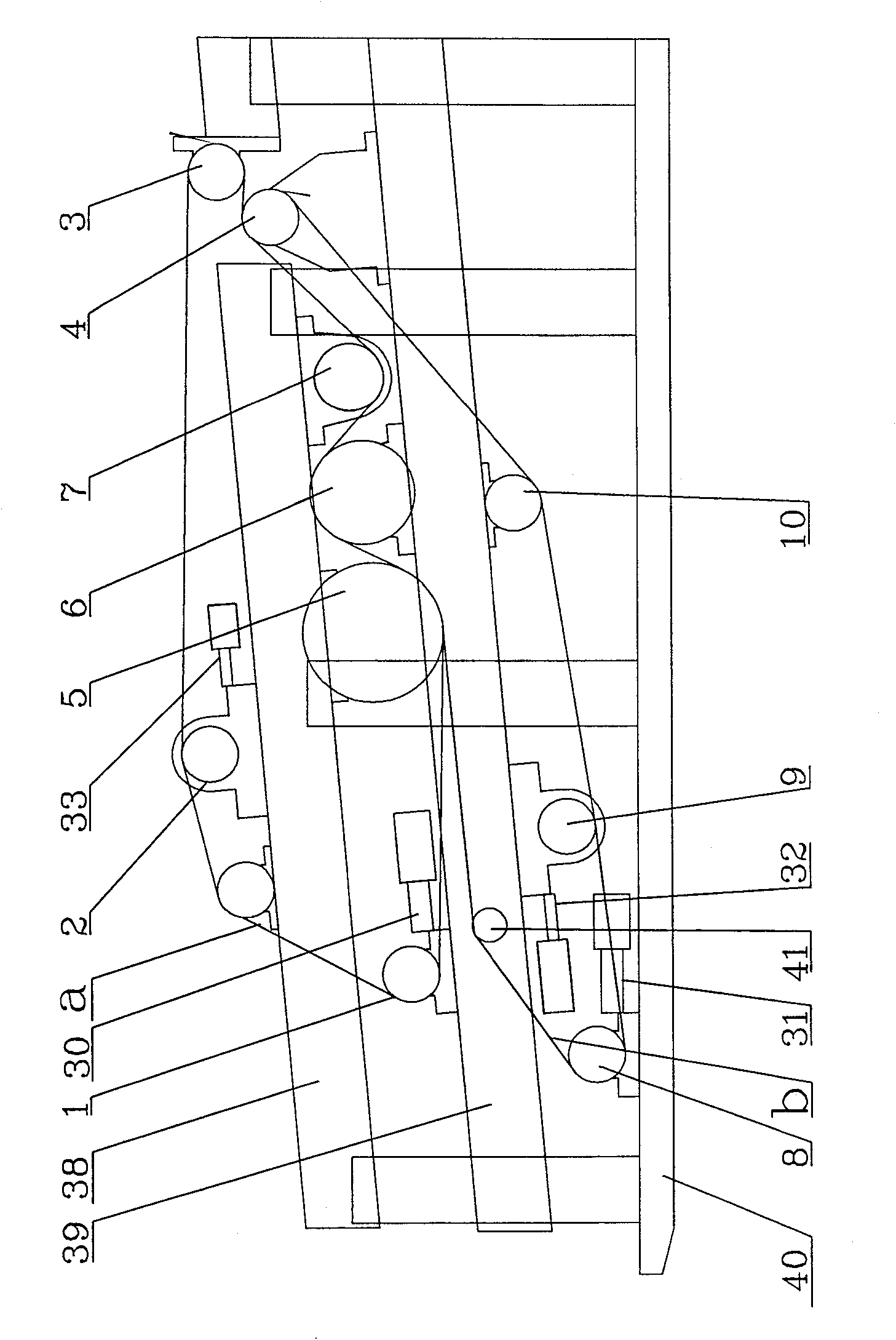

[0036] The solid-liquid separation equipment in this embodiment is equipped with two press dehydration zones, low pressure and high pressure. For the structure of the press dehydration zone in the embodiment, see Figure 1-3 .

[0037] see figure 1 , 2 , the upper pressure belt a in the low-pressure press area of this embodiment wraps around the idler roller 1, the correction roller 2, the idler roller 3, the main drive roller 4, the idler roller 7, the press roller 6, and the idler roller 5; the lower filter belt b wraps Idler roller 8, idler roller 5, press roller 6, idler roller 7, main drive roller 4, idler roller 10, deviation correction roller 9. As shown in the figure, idler rollers 1, 3, 5, 7, 8, 10, correction rollers 2, 9, main drive roller 4, and press roller 6 are installed on the upper frame 38, the lower frame 39 and the bottom of the frame respectively. Rack 40. The upper pressure belt a wrapped around the outer bottom of the idler 1 and the lower filter ...

Embodiment 2

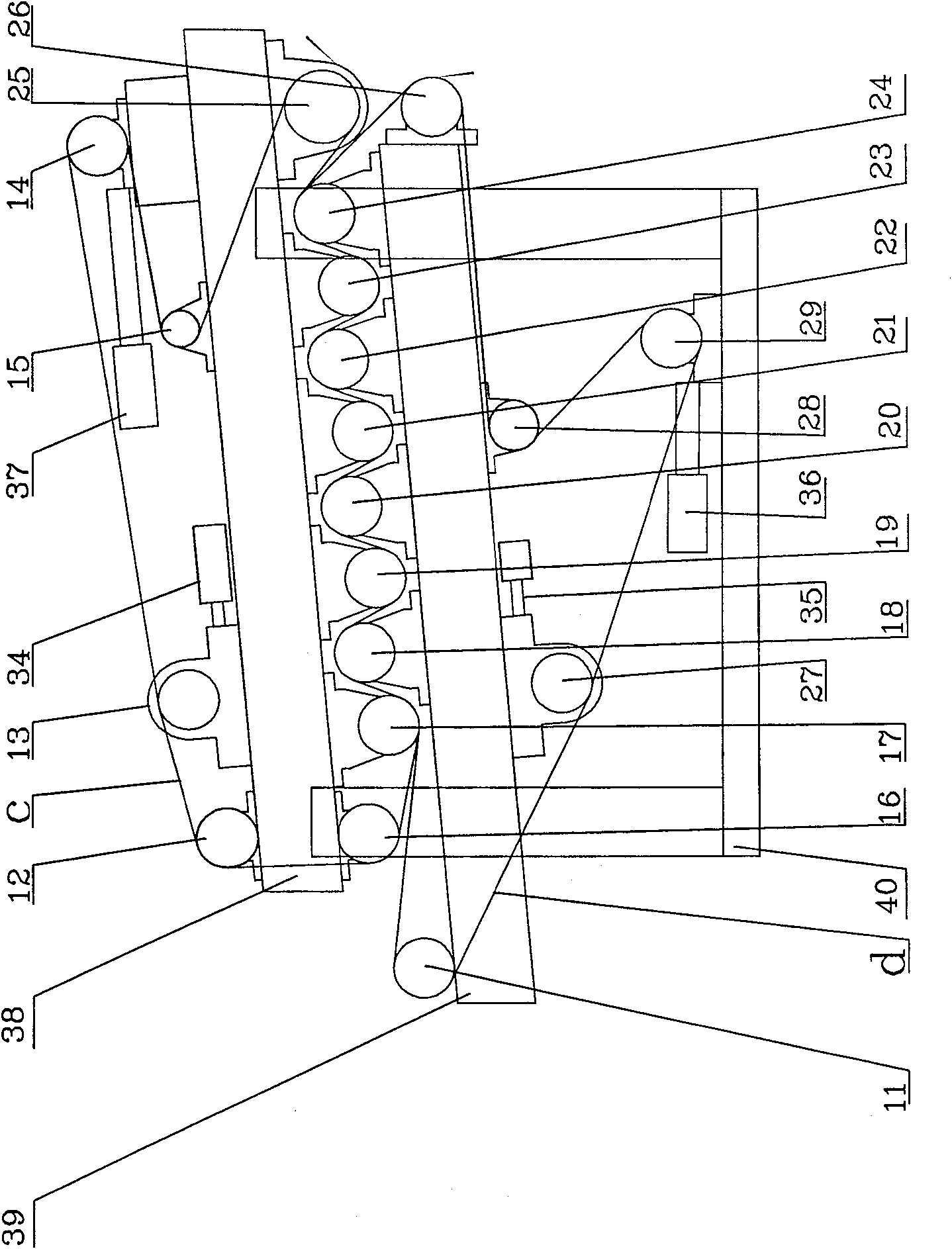

[0051] The solid-liquid separation equipment in this embodiment is equipped with three press dehydration zones of low pressure, medium pressure and high pressure. For the structure of the press dehydration zone in the embodiment, see Figure 4 , 5 .

[0052] The structure of the low pressure press zone of this embodiment is the same as that of the low pressure press zone of embodiment 1; the structure of the middle press zone is the same as that of the high pressure press zone of embodiment 1. The structure of the high pressure press section see Figure 5 , the upper pressure belt e wraps around the idler roller 42, the correction roller 43, the tension roller 47, the idler roller 45, the main drive roller 54, the press roller 53, the idler roller 52, the press roller 51, the idler roller 50, and the idler roller 49, The lower filter belt f wraps around the idler roller 48, the idler roller 50, the squeeze roller 51, the idler roller 52, the squeeze roller 53, the idler roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com