Toothed wheel single flank engagement measuring apparatus and method

A single-sided meshing and measuring device technology, which is applied in the direction of measuring devices, using optical devices, and using optical devices to transmit sensing components, etc., can solve the problems of backward measuring systems and cannot meet fast and accurate measurements, and achieve high measurement accuracy. Wide application range and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the present invention will be further described:

[0051] 1. Mechanical device

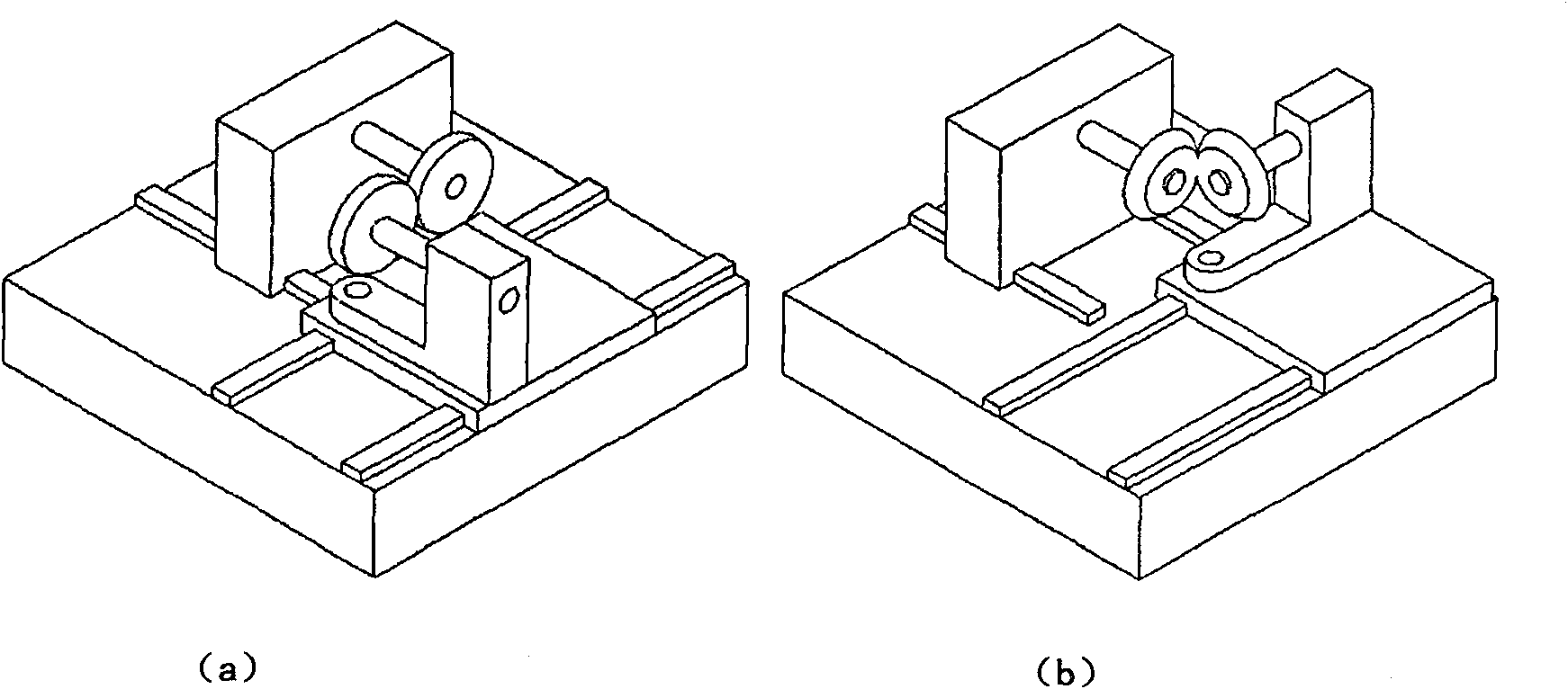

[0052] In order to make the instrument have the function of measuring cylindrical gears and bevel gears, the present invention installs the standard gear and the measured gear on two horizontal parallel shaft systems, the schematic diagram is as follows figure 1 As shown in (a), when measuring bevel gears, one of the shaft systems needs to be rotated 90 degrees on the common plane (parallel to the horizontal plane) of the two shaft systems. The schematic diagram is shown in the attached figure 1 As shown in (b), since the shaft system rotates in the same horizontal plane, the center of gravity will not move up, which ensures the measurement accuracy of the bevel gear.

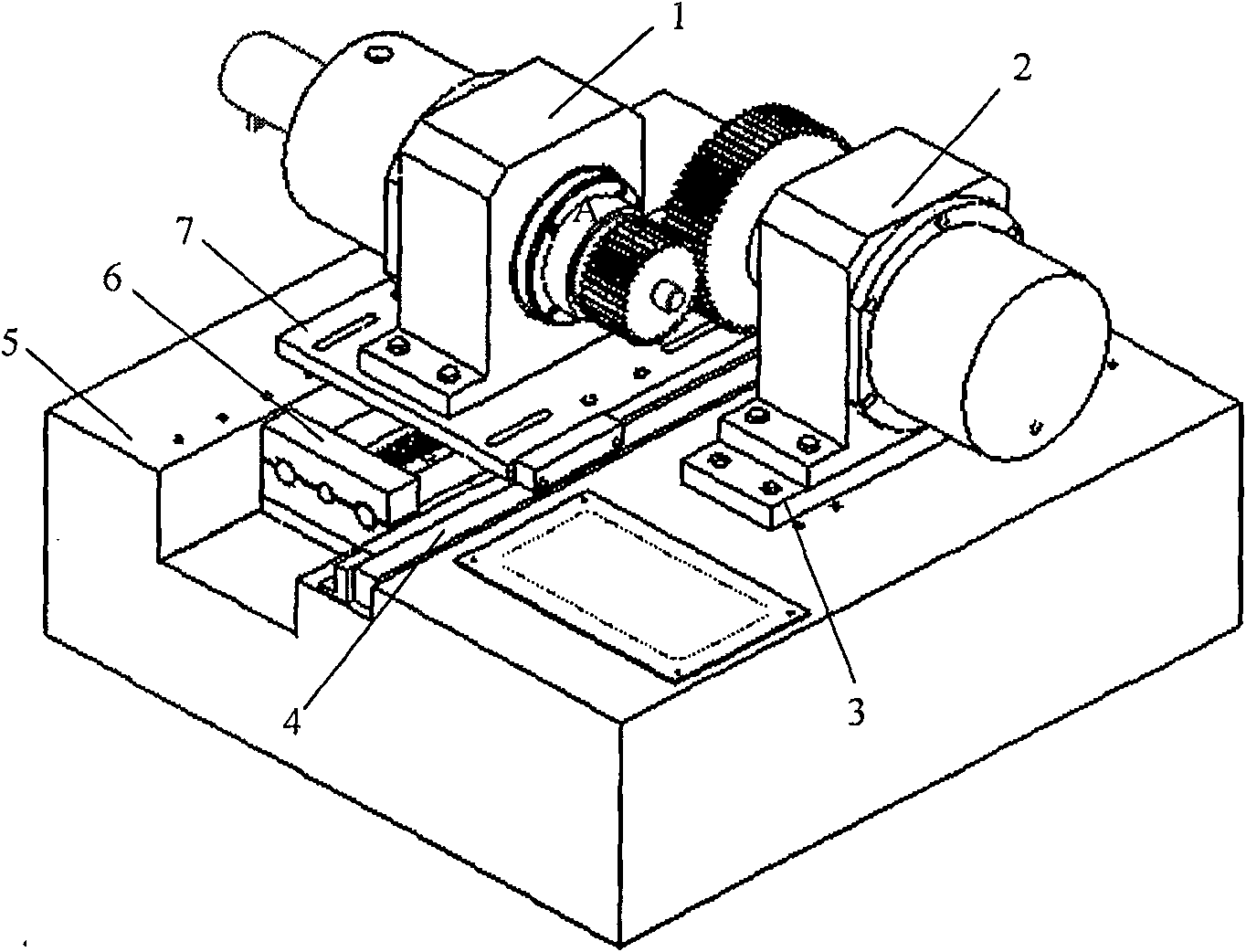

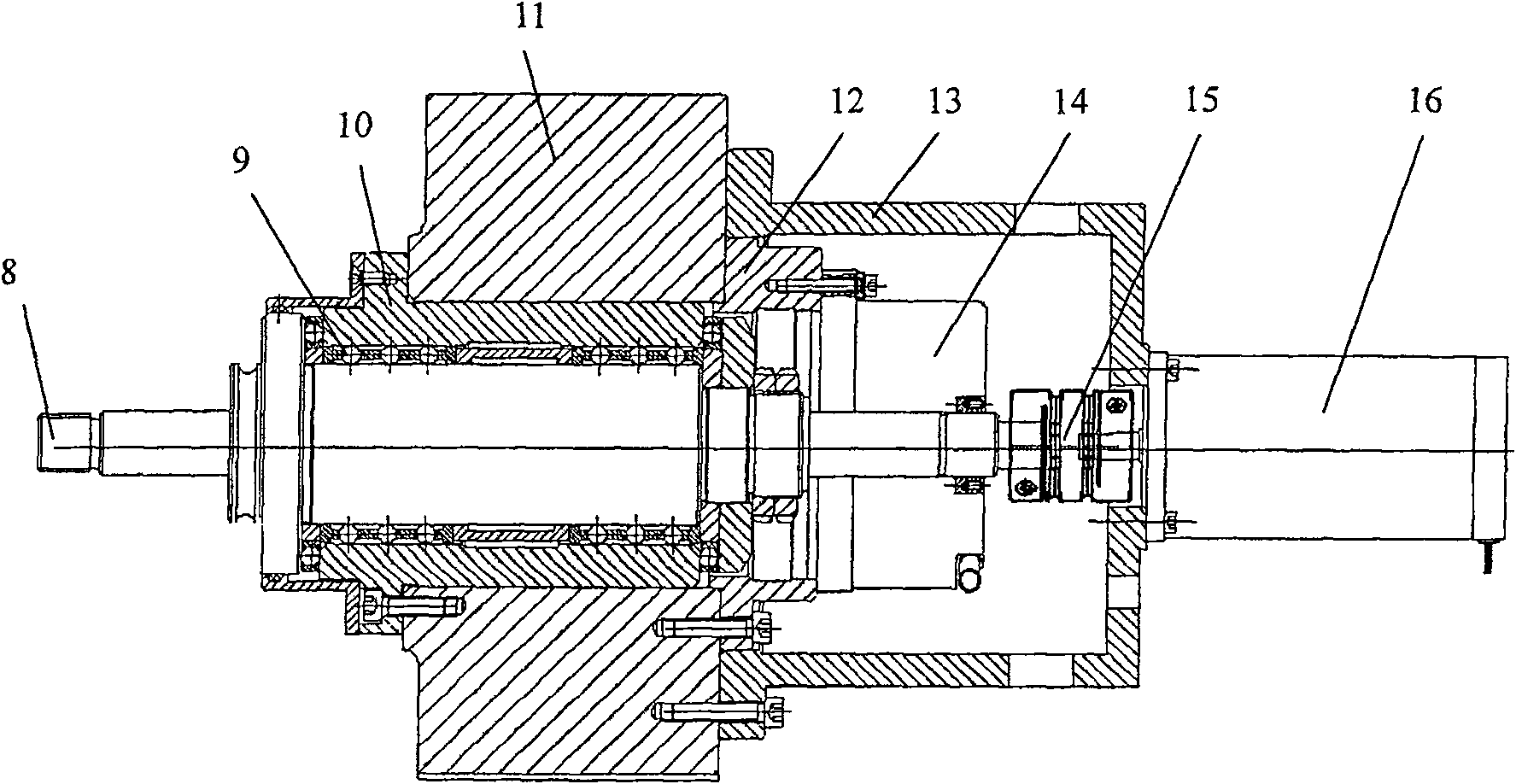

[0053] The mechanical device of the present invention is composed of a support, a servo mechanical system, a spindle system and a detection system. The support includes the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com