Method for continuous production of polyamide

A technology for polyamide and amidation, which is applied in the field of continuous preparation of polyamide, can solve the problems of increased addition of end group modifiers, difficulty in preparing polyamide, change in residence time, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

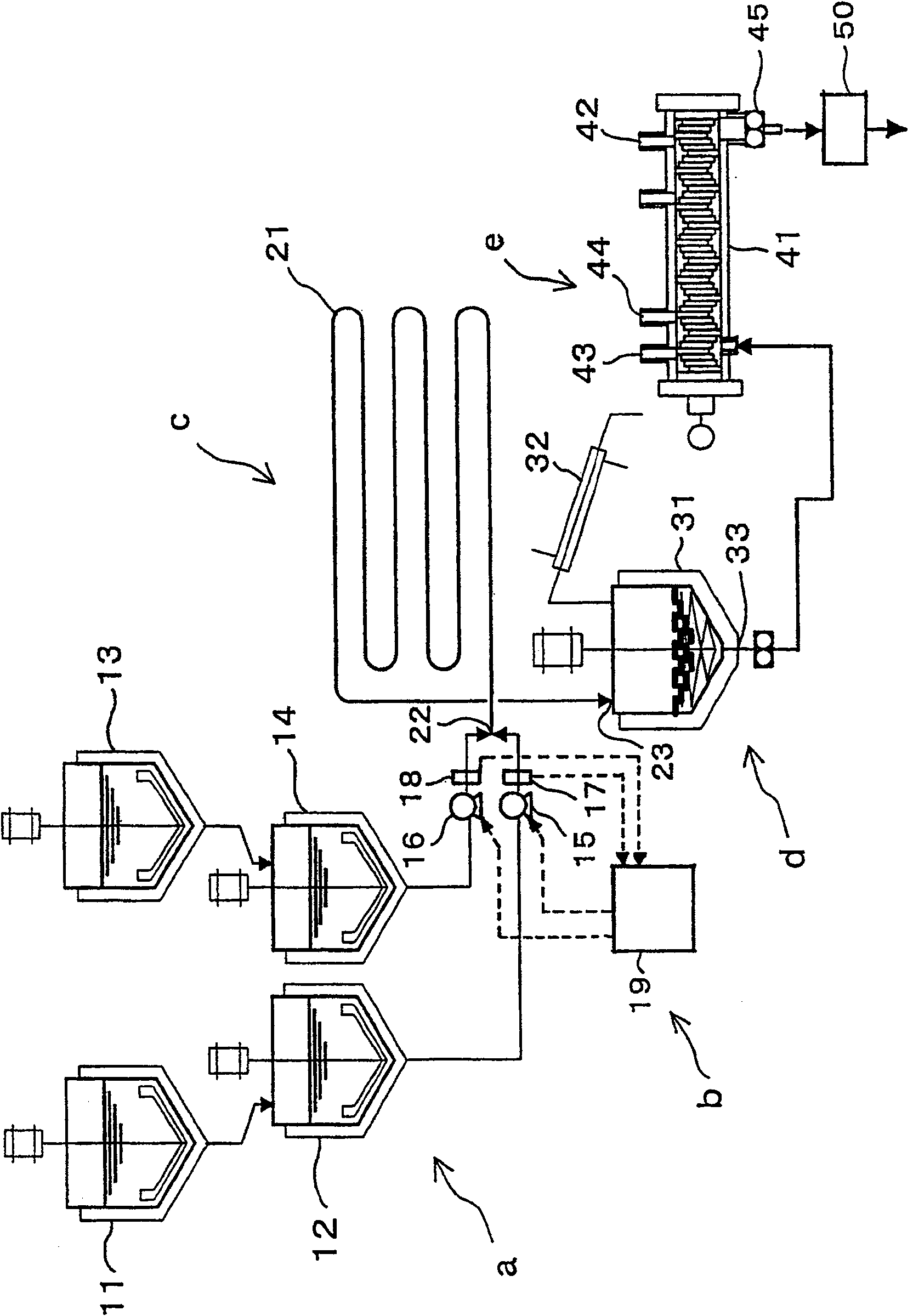

[0085] As the production method using the melt polymerization of polyamide, a production method such as batch type, batch type and solid phase polymerization, and continuous production using a multi-stage polymerization reactor can be performed. The melt viscosity control of the present invention can be used in these conventionally known production methods. However, in continuous production, it is necessary to immediately control the quality of the prepared polymer and feed it back to the production process to produce a polymer of a certain quality for a long time. Therefore, the melt viscosity control of the present invention is particularly preferred for the continuous production of polyamide. .

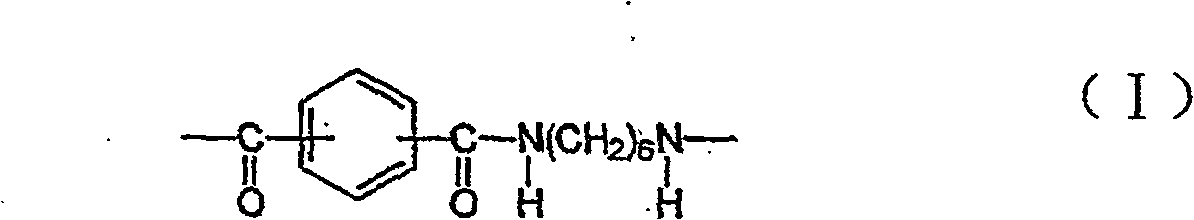

[0086] The continuous production method of the present invention can be applied to any one of aliphatic polyamides and aromatic-containing polyamides, and the polyamide includes at least one selected from, for example, the above repeating units (I) to (V).

[0087] Polyamide has an aro...

Embodiment 1

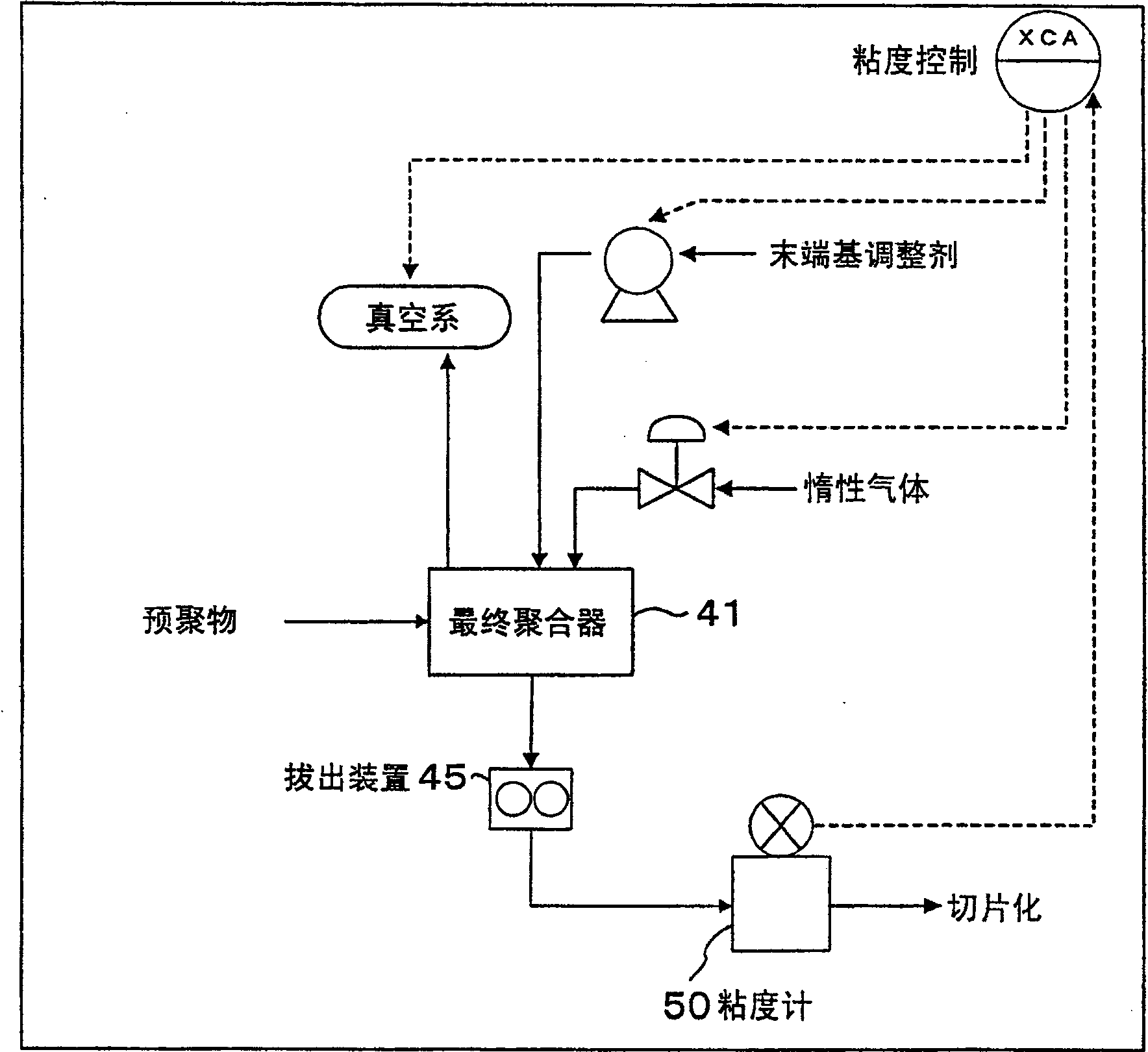

[0212] The polyamide prepolymer ([RV]1.61) containing adipic acid and metaxylylenediamine as the main raw materials is supplied to a reaction temperature of 255°C, atmospheric pressure (no vacuum operation), and screw rotation speed of 50rpm. In the reactor SCR of the conditions, the final polymerization is carried out. The flushing amount of nitrogen (purity 99.999% or more) is automatically controlled by the indicated value of the melt viscometer. With an average residence time in SCR of 10 minutes, a polyamide resin with an average [RV] of 2.37 and a standard deviation [σ] of 0.02 was prepared. The average value of [RV] and standard deviation [σ] are calculated from the measurement results of 20 samples taken at intervals of 10 minutes or more.

Embodiment 2

[0214] Except that the vacuum degree in the reactor SCR was set to a fixed value of 865 hPa, the same procedure as in Example 1 was performed. The average value of [RV] of the prepared polyamide resin was 2.38, and the standard deviation [σ] was 0.01.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com