Direction reduction and electric furnace smelting-separation preparation process of vanadium-titanium magnetite cold bound pellet

A technology of vanadium-titanium magnetite and production method, which is applied in the field of preparation of cold-consolidated carbon-containing pellets of vanadium-titanium-magnetite, and can solve the problem of low drying temperature and preheating burst of cold-consolidated carbon-containing pellets Reduction time, high C/Fe ratio, etc., to achieve the effect of greatly reducing pollution, reducing the overall cost of the product, and achieving good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

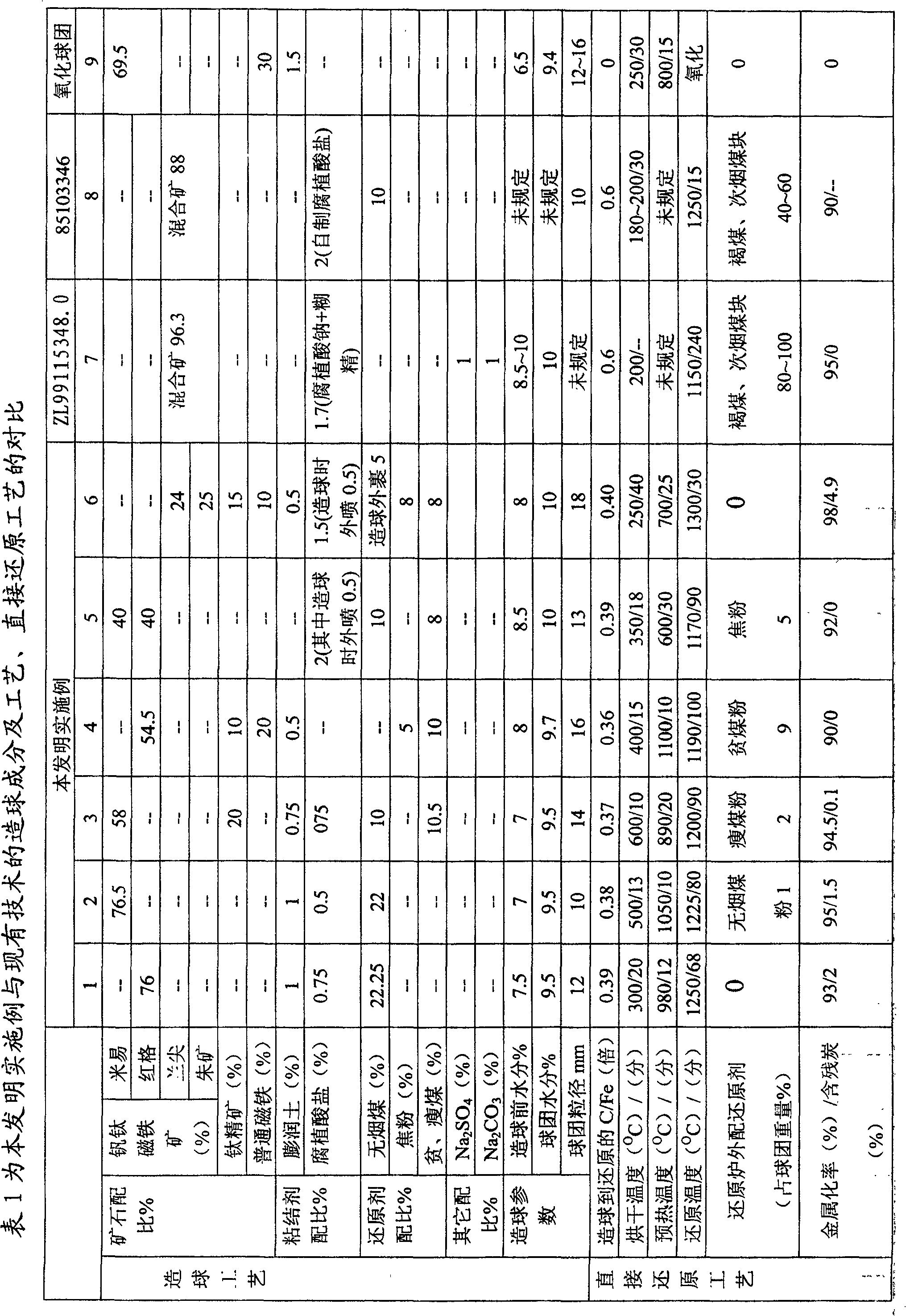

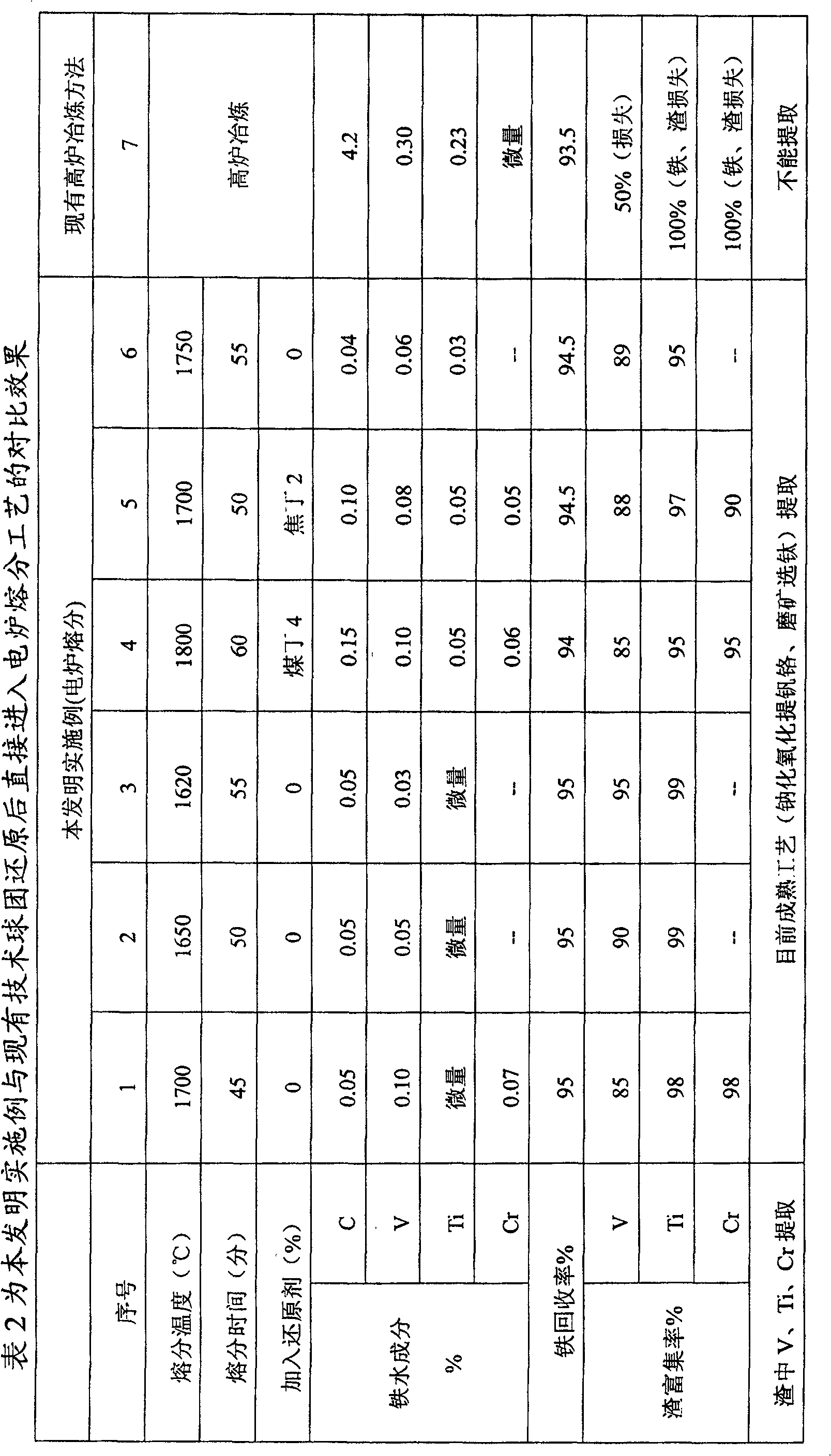

Embodiment 1

[0017] Example 1 This scheme is implemented in the coke oven gas comprehensive utilization project in Panzhihua, Sichuan. -200 mesh 55% vanadium-titanium magnetite concentrate (red grid ore: V 2 o 5 0.67%, Cr 2 o 3 : 1.3%, TiO 2 12.5%), -200 mesh 70% anthracite fine coal powder, -200 mesh 99% high-efficiency bentonite, -180 mesh 50% humate, respectively in proportions of 76.0%, 22.25%, 1.0%, and 0.75%. After mixing and grinding, the batch materials enter the pelletizing machine to form 12mm cold-solidified carbon-containing pellets. Before pelletizing, the moisture content of the material is 7.5%, the moisture content of the pellets is 9.5%, and the C / Fe ratio of the pellets is 0.39. The drying temperature of the cold-consolidated carbon-containing pellets is 300°C, the preheating temperature is 980°C, the reduction temperature is 1250°C, the preheating-reduction time is 80 minutes, the metallization rate of the reduced pellets is 93.0%, and the residual carbon content is ...

Embodiment 2

[0018] Example 2 This scheme is implemented in the coke oven gas comprehensive utilization project in Panzhihua, Sichuan. -200 mesh 65% vanadium-titanium magnetite concentrate (Panzhihua Miyi Baima ore, chrome-free, V 2 o 5 0.78%, TiO 210%) and -180 mesh 70% anthracite clean coal powder and -200 mesh more than 99% high-efficiency bentonite, -180 mesh 50% humate in proportions of 76.5%, 22%, 1.0%, and 0.5% respectively. After mixing and grinding, the batch materials enter the pelletizing machine to form 10mm cold-solidified carbon-containing pellets. The moisture content of the material before pelletizing is 7.0%, the moisture content of the pellets is 9.5%, and the C / Fe ratio of the pellets is 0.38. The drying temperature of the cold-consolidated carbon-containing pellets is 500°C, the preheating temperature is 1050°C, the reduction temperature is 1225°C, the preheating-reduction time is 90 minutes, the metallization rate of the reduced pellets is 95.0%, and the residual car...

Embodiment 3

[0019] Example 3 This scheme is implemented in the coke oven gas comprehensive utilization project in Panzhihua, Sichuan. -200 mesh 70% vanadium-titanium magnetite concentrate (Panzhihua Miyi Baima ore, chromium-free, V 2 o 5 0.83%, TiO 2 8.0%) and -200 mesh 40% titanium concentrate (TFe34%, TiO 2 47.5%), -180 mesh 70% lean lean fine coal powder, -180 mesh 70% anthracite fine coal powder, -200 mesh 99% or more high-efficiency bentonite, -180 mesh 50% humate by 58% , 20%, 10%, 10.5%: 0.75%, 0.75% ratio ingredients. After mixing and grinding, the batch materials enter the pelletizing machine to form 14mm cold-solidified carbon-containing pellets. The moisture content of the material before pelletizing is 7.0%, the moisture content of the pellets is 9.5%, and the C / Fe ratio of the pellets is 0.37. The drying temperature of the cold-consolidated carbon-containing pellets is 600°C, the preheating temperature is 890°C, the reduction temperature is 1200°C, the preheating-reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com