Method for manufacturing laminated hd (high-density) paper with good oxygen-barrier properties, and hd paper obtained thereby

A performance, good technology, applied in the direction of cellulose plastic layered products, chemical instruments and methods, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

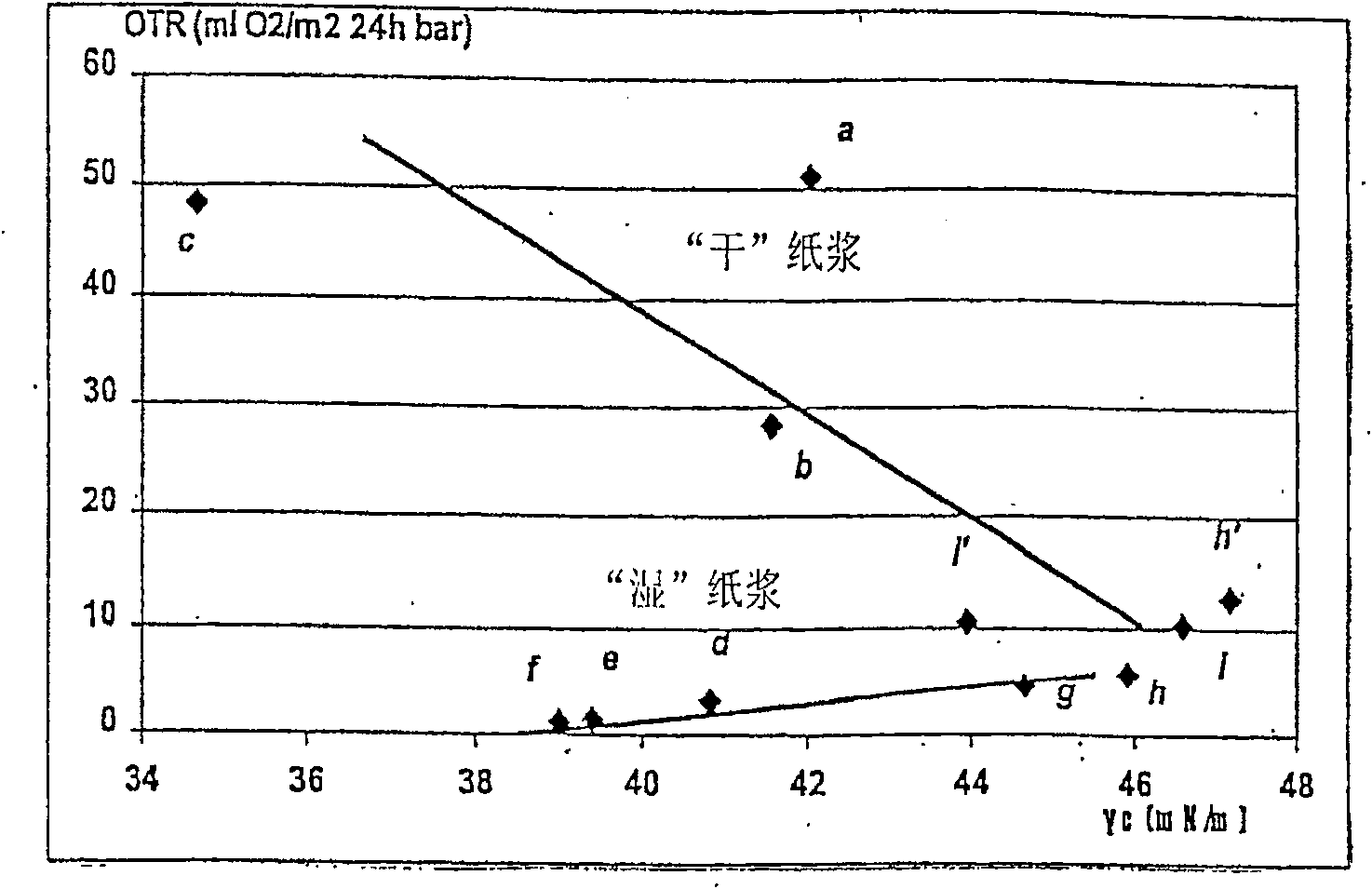

[0030] Example 1: Comparison of Oxygen Barrier of Wet Sulphite Pulp Made Paper Sheets and Dry Sulphite Pulp Made Paper Sheets

[0031] Table 1 shows that under the same coating conditions, the oxygen barrier of paper made from wet sulphite pulp is significantly better than that of paper made from dry sulphite pulp.

[0032] Table 1 : Test results for HDPE covered high density paper and OTR made from dry (sulfate) and "wet" (sulfite) pulp, respectively. The surface energy of each individual paper is also given. The surface energy of the HDPE (CG8410) film is 38.4 mN / m.

[0033] sample

[0034] *in ml O 2 / m 2 24h atm gives

example 2

[0035] Example 2: Comparison of the oxygen barrier of a sheet of paper made from wet sulphite pulp treated in a steaming chamber and a sheet of similar paper not treated in a steaming chamber

[0036] The treatment in the steam chamber lowers the surface energy of the paper and makes HDPE a better barrier. This does indicate an improved basis between materials. This leads to a lowering of the average surface energy and thus the ΔG (Gibbs free energy) of the formation of new crystalline structures at the surface of the storage paper by way of storage (especially for LDPE). This results in a lower OTR. This can be seen from Table 2 and Table 3. Here CG 8410 is HDPE type, CA7230 is LDPE type. The same applies to Table 4 above.

[0037] Table 2: Test results for OTR of HDPE coated HD paper made from "wet" (sulfite) pulp (FL812). CA7230: 36.2mN / m, FL812: 40.4mN / m

[0038] polymer

Roll pressure, KPa

OTR

ml / m 2 24h atm

Stored OTR

ml / m 2...

example 3

[0041] Example 3: Comparison of the oxygen barrier of a sheet of paper made from wet sulphite pulp with internal sizing and the oxygen barrier of a sheet of the same paper without internal sizing

[0042] Table 4: Test results for OTR of HDPE coated high density paper made from "wet" (sulfite) stock (Candor paper) without internal sizing with AKD stock. 50.9mN / m

[0043] polymer

[0044] The oxygen barrier of Candor papers was less satisfactory than internally sized papers. However the barrier is in any case better than that obtained with internal sizing of high density papers made with 60, 90 or 100% pre-dried sulphate pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com