Equipment, method and positioning installation for printing patterns on surface of small round ball

A surface printing and ball technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problem of not being able to print patterns on the surface of small balls in large quantities, and achieve the effect of reducing printing difficulty and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

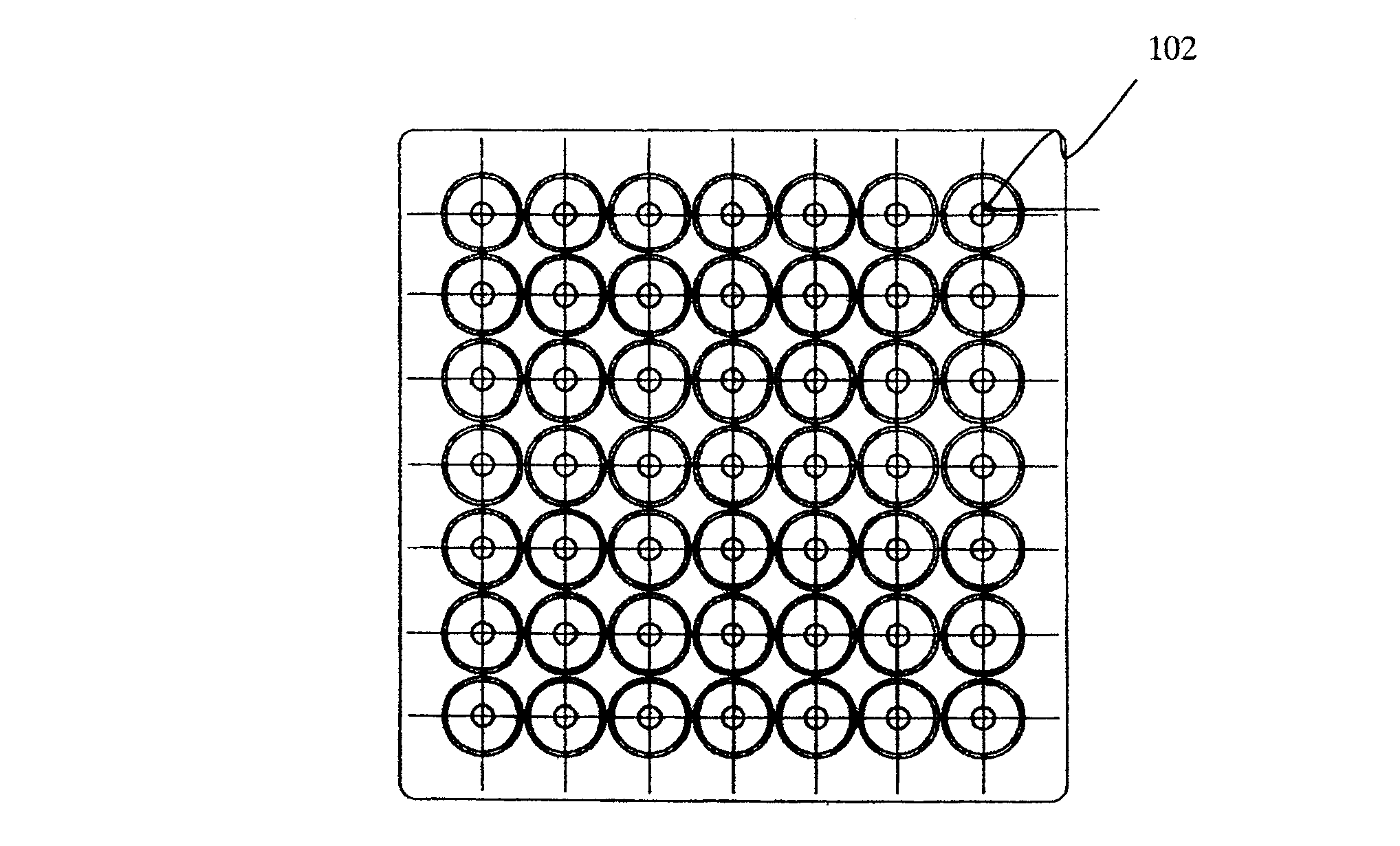

[0033] The device for printing patterns on the surface of tiny balls provided by the present invention comprises: a machine-connected deck installed on the substrate rack of a pad printing machine, and a ball clamp installed on the machine-linked deck; the ball A plurality of positioning holes are arranged in an array on the fixture, and the positioning holes accommodate the microspheres, and a part of the convex surface of the microspheres or both upper and lower convex surfaces are exposed outside the positioning holes.

[0034] The method key that the present invention solves is to have conceived special fixture (or claiming splint), so whole production can form a set of semi-automatic assembly line.

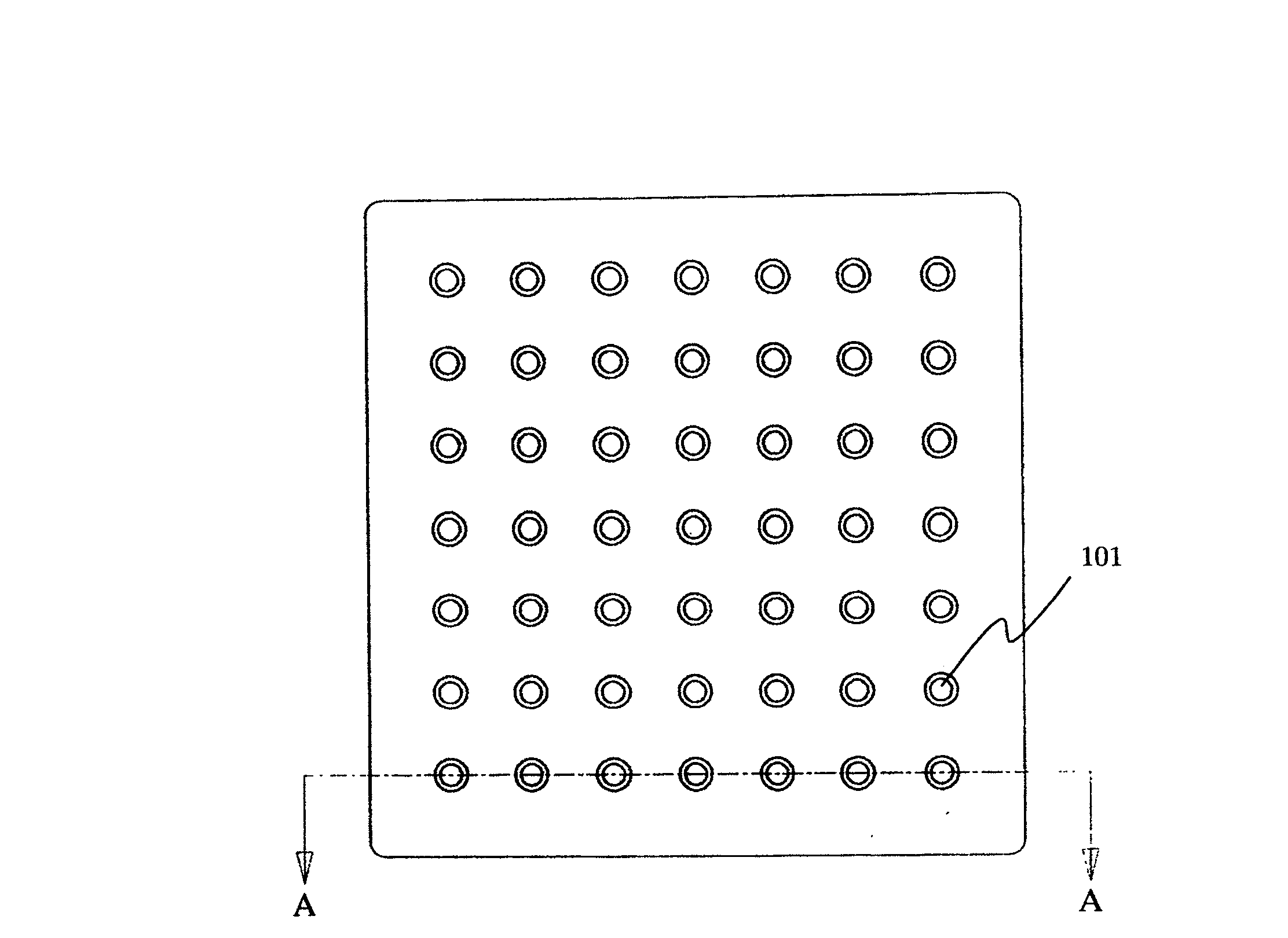

[0035] Such as figure 1 , figure 2 and image 3 As shown, the small ball clamp is a pair of splints, including: an upper splint with a plurality of bead stabilizing holes 101 arranged in an array; a lower splint with a plurality of bead clamping holes 102 corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com