Optical fibre grating digital demodulation method and system based on autocorrelation principle

A technology of fiber grating and demodulation method, which is applied in the coupling of optical waveguide and the transmission of sensing components by optical devices, etc., which can solve the problem of low measurement accuracy and high price of fiber grating sensing system demodulation technology, which cannot meet the actual needs of the project And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the drawings and embodiments.

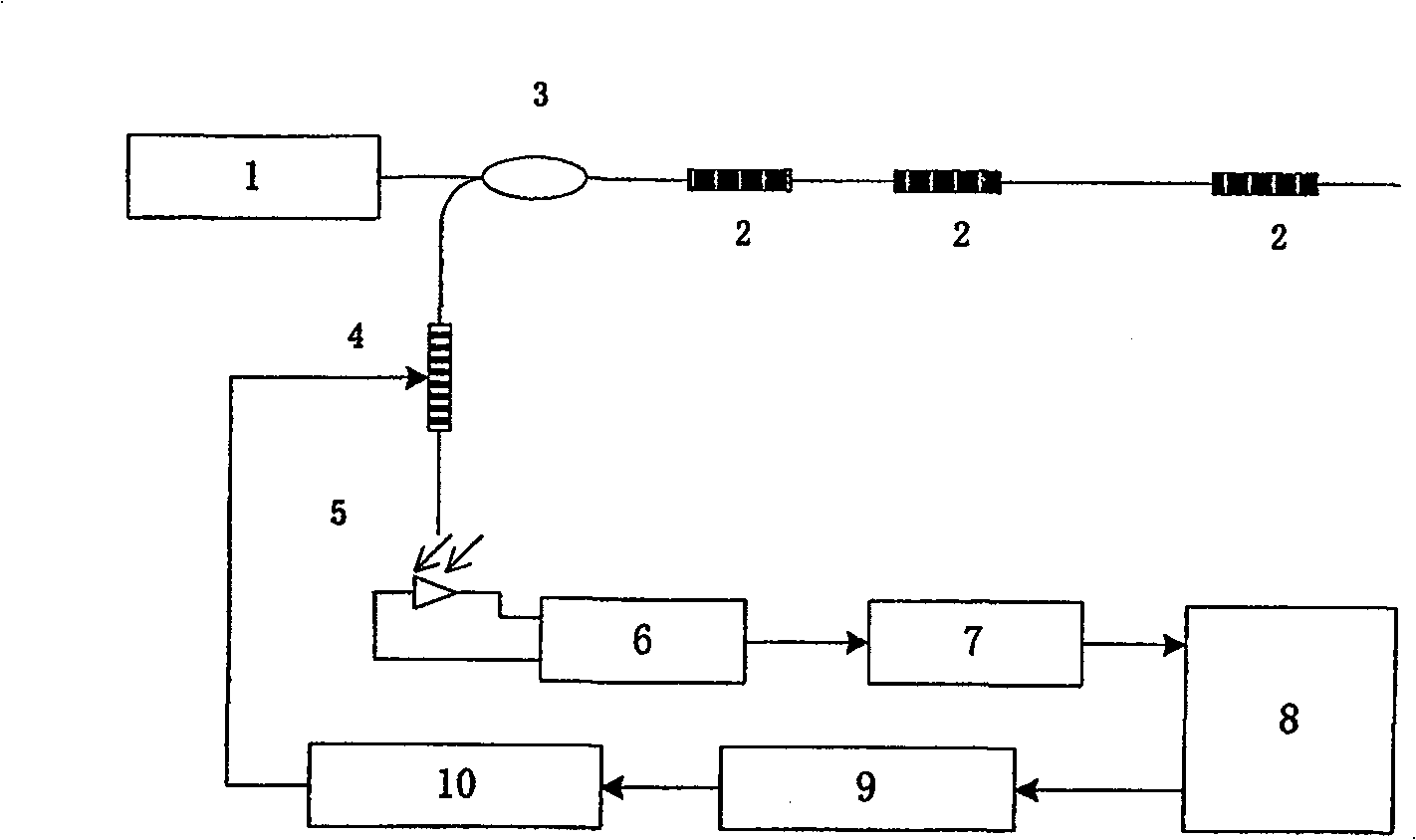

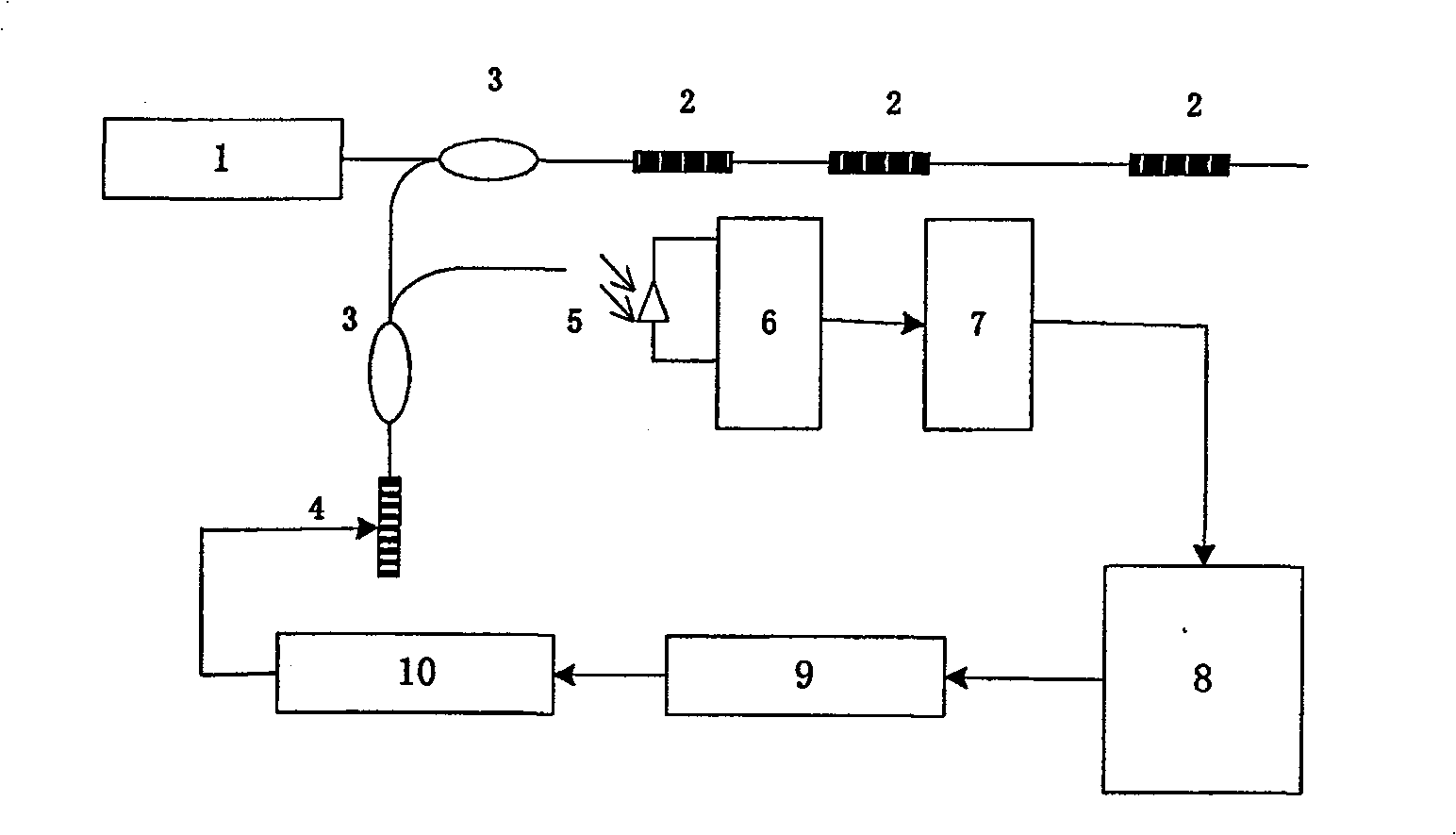

[0070] figure 1 , figure 2 In, the fiber grating autocorrelation digital demodulation system includes a broadband light source 1 and a number of serially connected fiber grating sensors 2. The light source 1 is connected to the fiber grating sensor 2 through a 2×2 coupler 3, and the coupling device is also connected to a tunable The filter 4 is connected, and the tunable filter 4 is connected to the photodetector 5. The photodetector 5 is connected to the preamplifier 6, the digital-to-analog converter 7, and the digital-to-analog converter 7 is connected to the digital controller 8 using the DSP chip. The input terminal is connected; the output terminal of the digital controller 8 is connected to the control input terminal of the tunable filter 4 via the electromechanical controller 9 and the electromechanical modulation system 10 in turn. The tunable filter 4 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com