Asphalt felt spreader

A technology for pasting machines and linoleum, which is applied to roads, road repairs, roads, etc., can solve the problems of poor paste uniformity and effect, high labor intensity of construction personnel, and unsatisfactory construction, so as to achieve strong adhesion and good paste. The effect of high efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

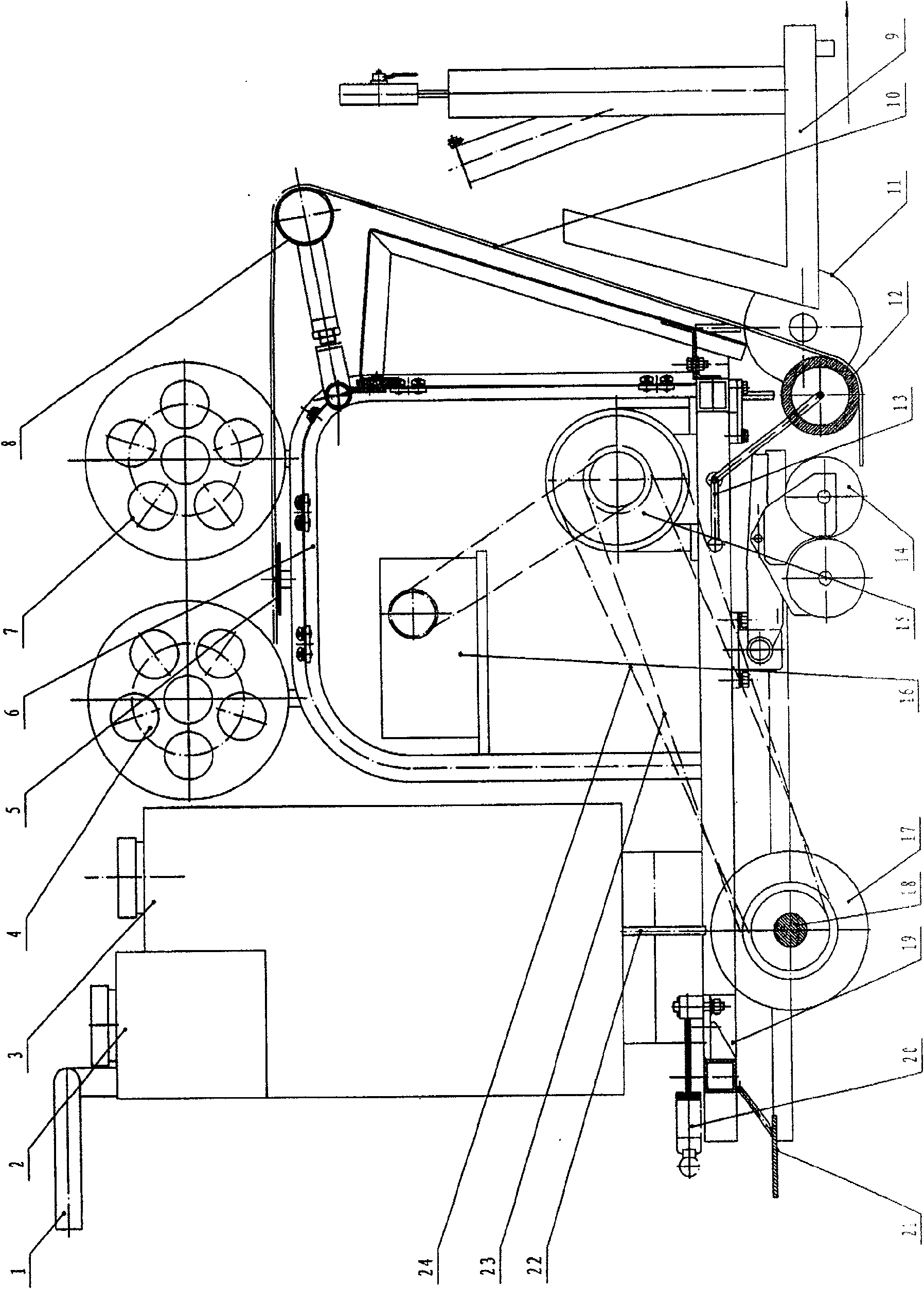

[0020] in figure 1 , 6 In this implementation, the felt applicator consists of the operating handle 1, the fuel tank 2, the water tank 3, the rear delivery felt roller 4, the felt connector 5, the frame 6, the front delivery felt roller 7, the felt guide roller 8, and the burner 9. , Front traveling wheel 11, front rolling felt roll 12, front pressure roller tie rod 13, rear rolling felt roll 14, reducer 15, engine 16, rear traveling wheel 17, axle 18, base 19, clutch 20, rear rolling The wheel control rod 21, the drip tube 22, the low-speed sprocket chain mechanism 23, and the fast sprocket chain mechanism 24 are connected together.

[0021] On the base 19, a combustor 9 is fixedly connected and installed with a screw fastening coupling at the front end, and a clutch 20 is fixedly connected and installed with a screw fastening coupling at the rear end. Between the burner 9 and the clutch 20 on the base 19, the frame 6, the engine 16, the reducer 15, the water tank 3, the rear ro...

Embodiment 2

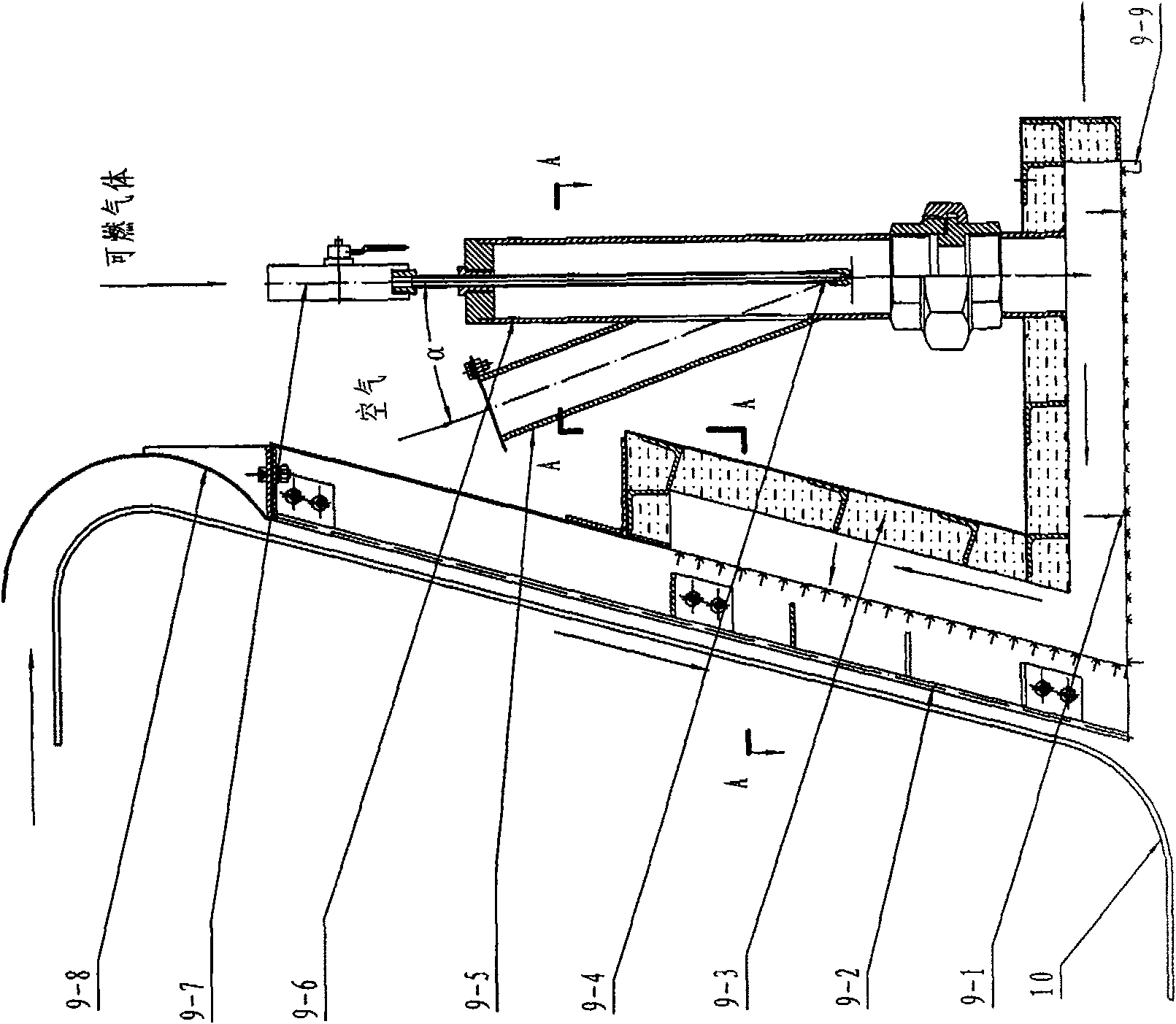

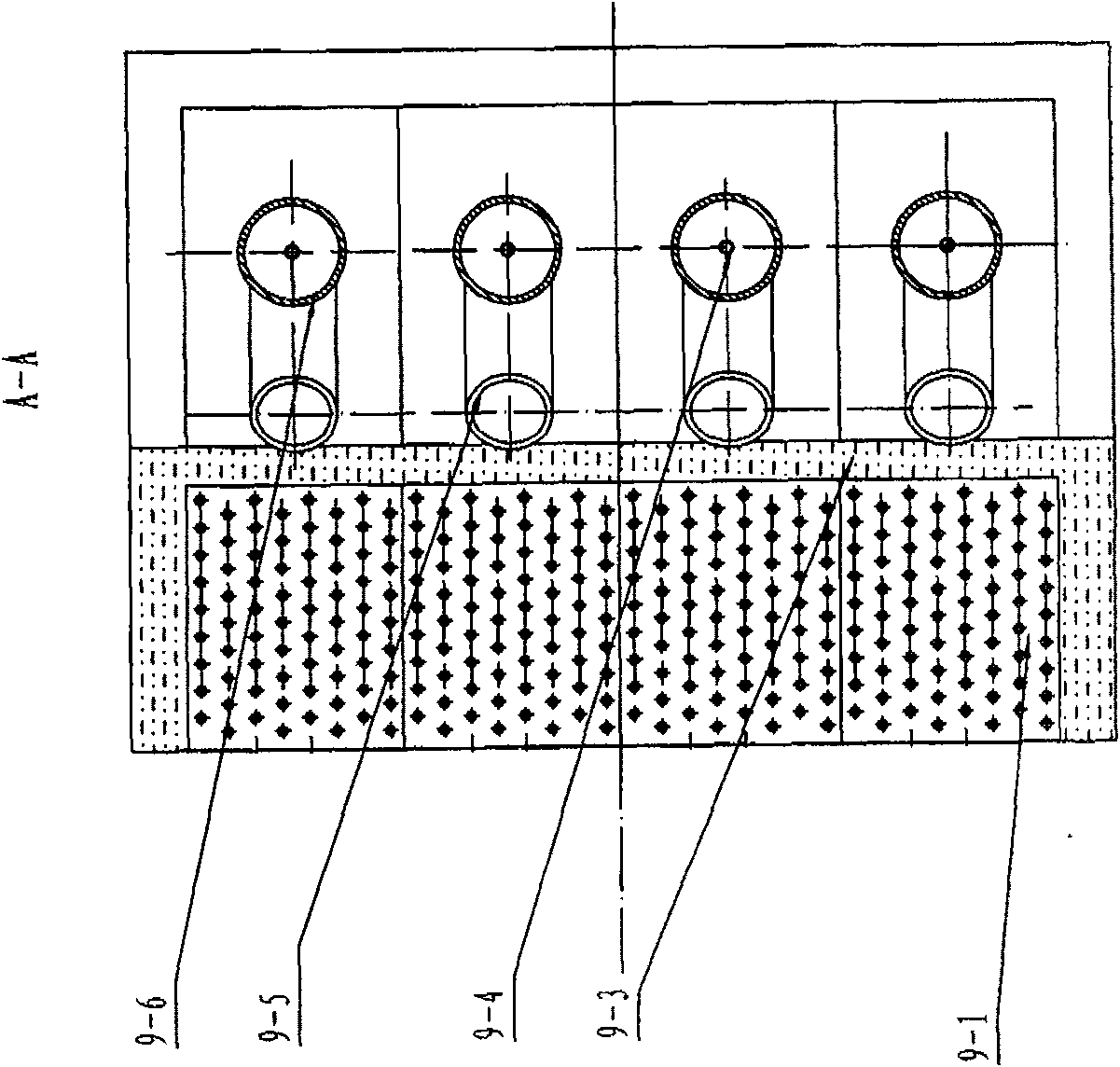

[0027] In this embodiment, the combined combustion chamber 9-1 is composed of 4 combustion chambers with exactly the same structure arranged in a row in the left and right direction. The combined combustion chamber 9-1 is equipped with 4 main mixing tubes 9-6, each of which is The pipe 9-6 communicates with a combustion chamber, and the side wall of each main mixing pipe 9-6 is fixedly connected with a threaded fastening connector to install an air suction pipe 9-5, which is connected to the main mixing pipe. 9-6 are connected, the angle α between the center line of the main mixing pipe 9-6 and the center line of the air suction pipe 9-5 is 10°, and the upper end of each main mixing pipe 9-6 is equipped with a gas control valve 9-7 , Each main mixing pipe 9-6 is equipped with a gas nozzle 9-4 connected with the gas control valve 9-7, and the gas nozzle 9-4 is located at the center line of the main mixing pipe 9-6 and the center of the air suction pipe 9-5 55mm below the line inter...

Embodiment 3

[0029] In this embodiment, the combined combustion chamber 9-1 is composed of 4 combustion chambers with exactly the same structure arranged in a row in the left and right direction. The combined combustion chamber 9-1 is equipped with 4 main mixing tubes 9-6, each of which is The pipe 9-6 communicates with a combustion chamber, and the side wall of each main mixing pipe 9-6 is fixedly connected with a threaded fastening connector to install an air suction pipe 9-5, which is connected to the main mixing pipe. 9-6 are connected, the angle α between the center line of the main mixing pipe 9-6 and the center line of the air suction pipe 9-5 is 20°, and the upper end of each main mixing pipe 9-6 is equipped with a gas control valve 9-7 , Each main mixing pipe 9-6 is equipped with a gas nozzle 9-4 connected with the gas control valve 9-7, and the gas nozzle 9-4 is located at the center line of the main mixing pipe 9-6 and the center of the air suction pipe 9-5 80mm below the line inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com