Treatment technology of producing sulfuric acid from alkylated spent sulfuric acid through high temperature decomposition

A technology of alkylating waste sulfuric acid and pyrolysis, which is applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of not introducing the process in detail, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

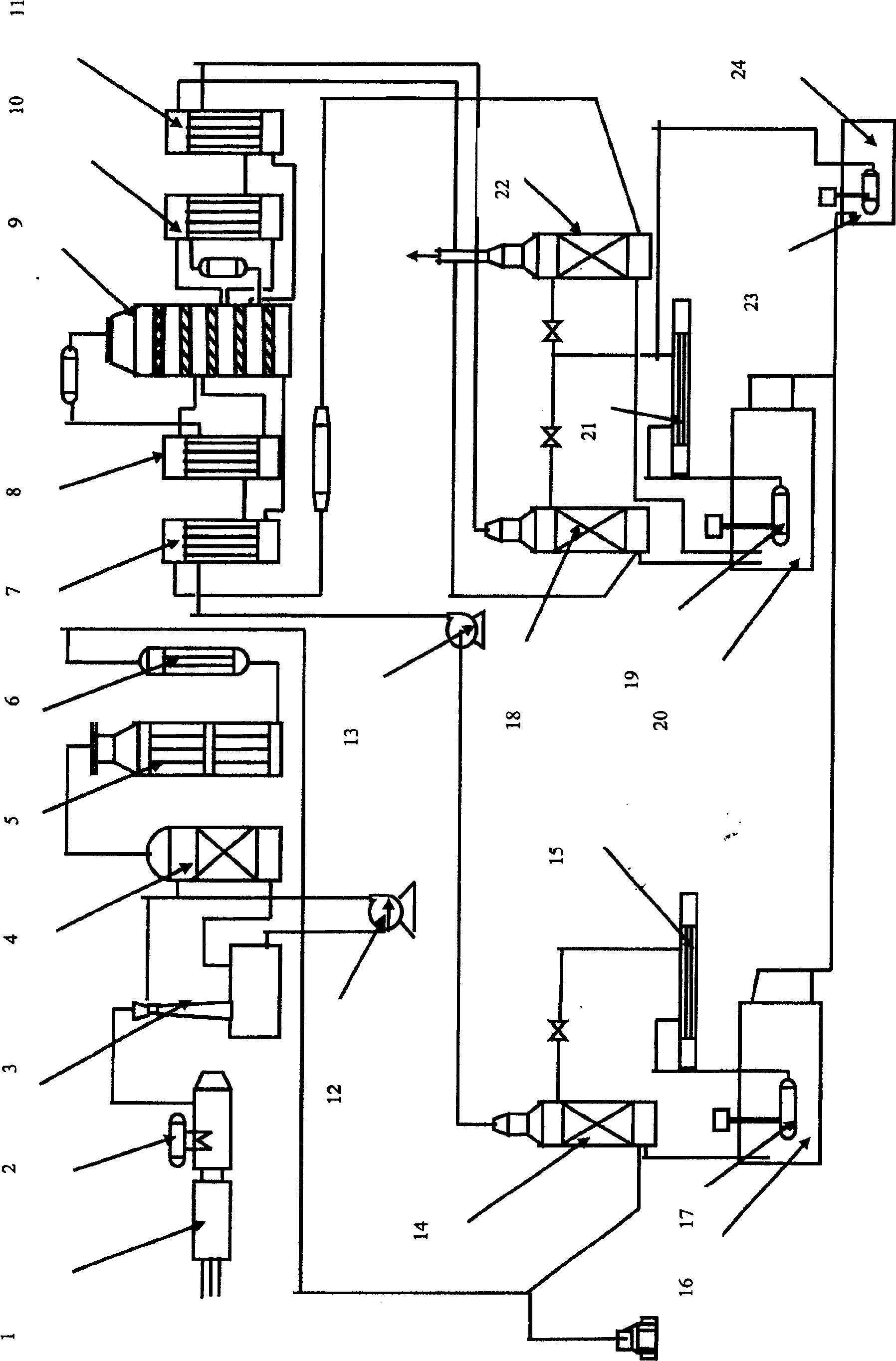

Method used

Image

Examples

example 3

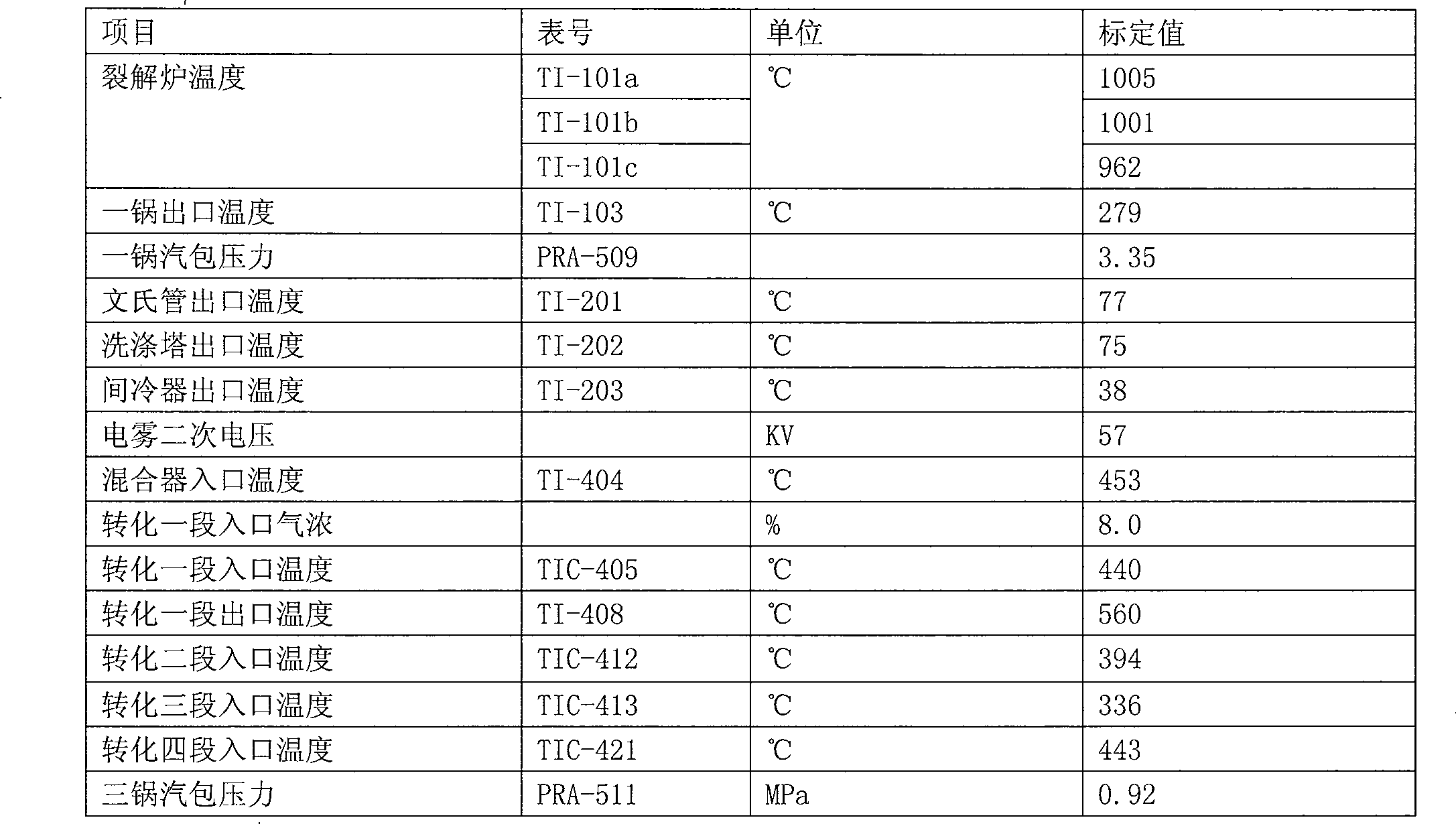

[0045] Example 3 Product Quality

[0046] concentration% Measured value in V301, V302 dry 95.5 absorb 98.0

example 4

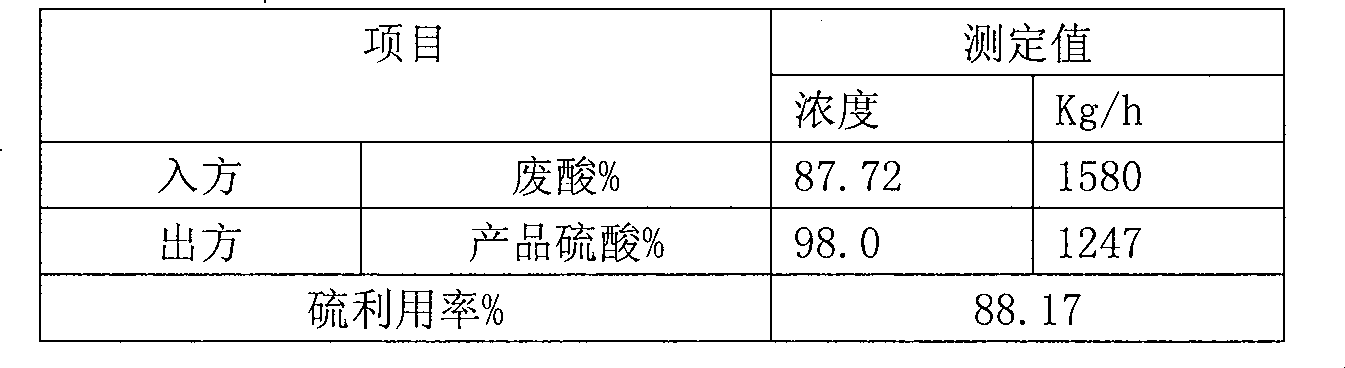

[0047] Example 4 Energy consumption index of device operation

[0048]

[0049] measured value measured value measured value 1 fresh water 15.04 12.05 2.17 2 Electricity 415.8 333 99.9 3 1.0MPa steam -5.63 -4.51 -356.25 4 deoxygenated water 6.17 4.94 45.45 5 gas 1.03 0.83 830 total 621.27

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com