Solid hazardous waste cracking technology and complete equipment

A complete set of equipment and hazardous waste technology, applied in the field of harmless treatment of hazardous solid waste, can solve problems such as waste of available resources for hazardous solid waste, environmental damage, etc., and achieve the effects of promoting cracking efficiency, avoiding potential safety hazards, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

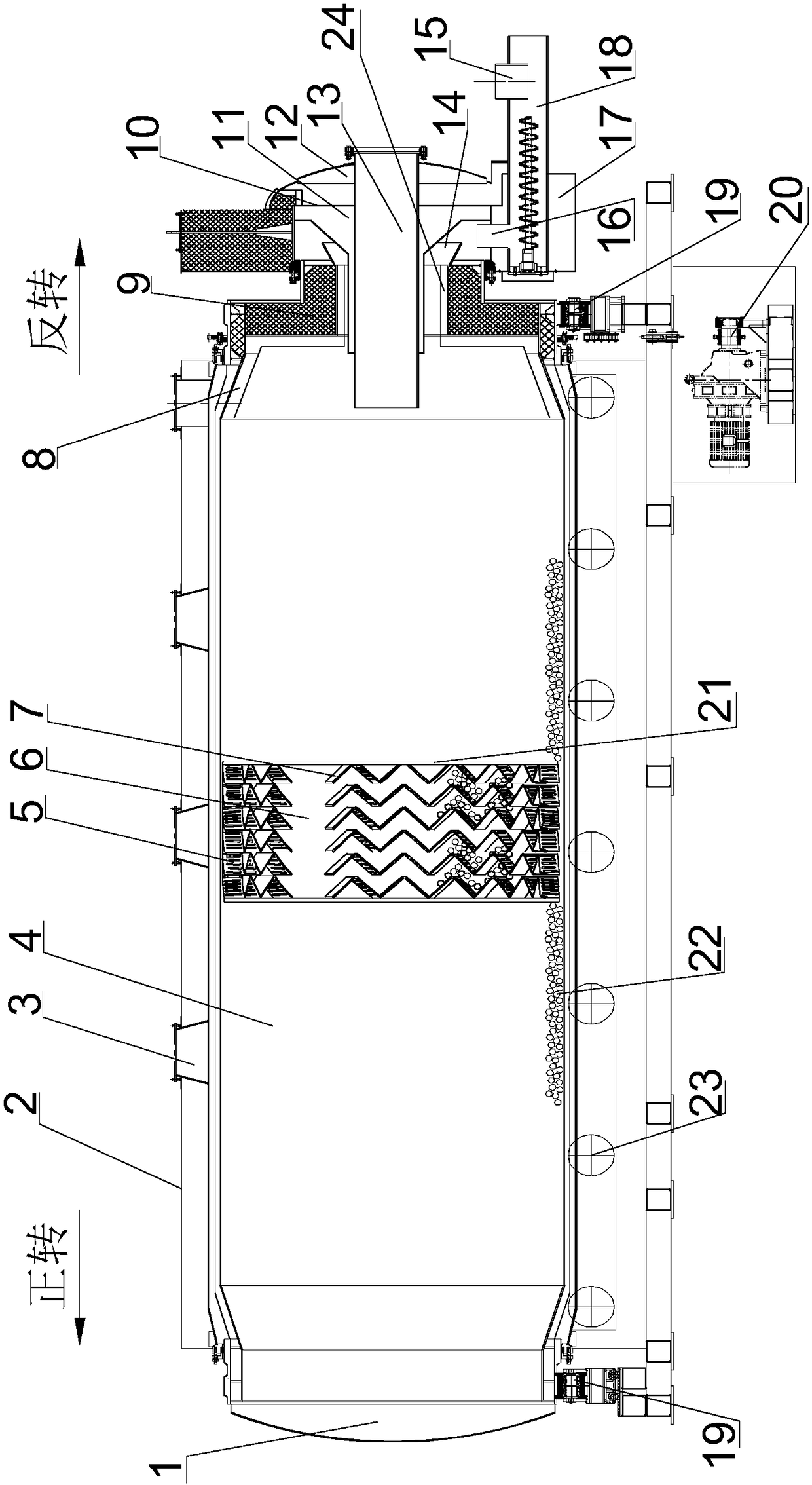

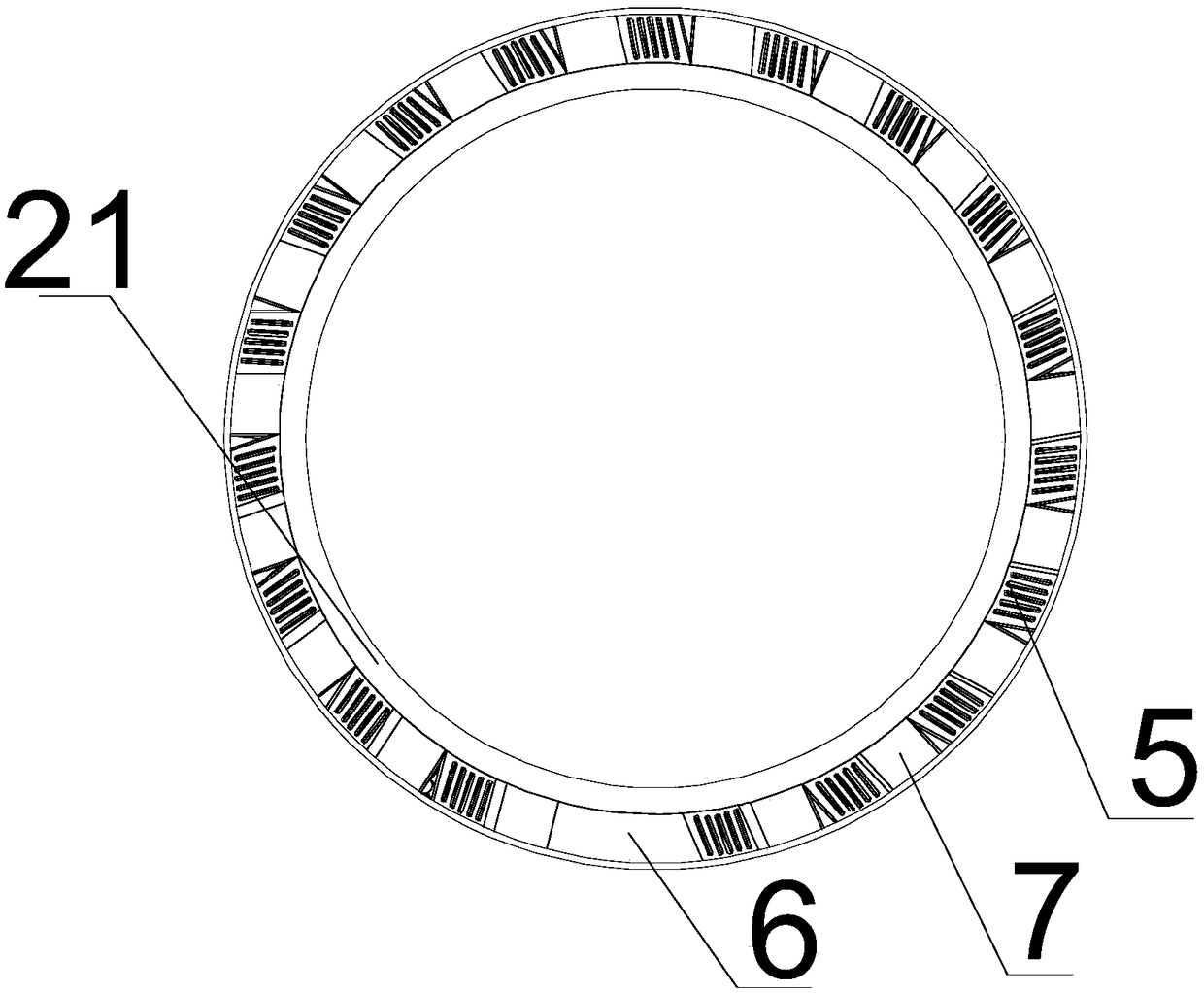

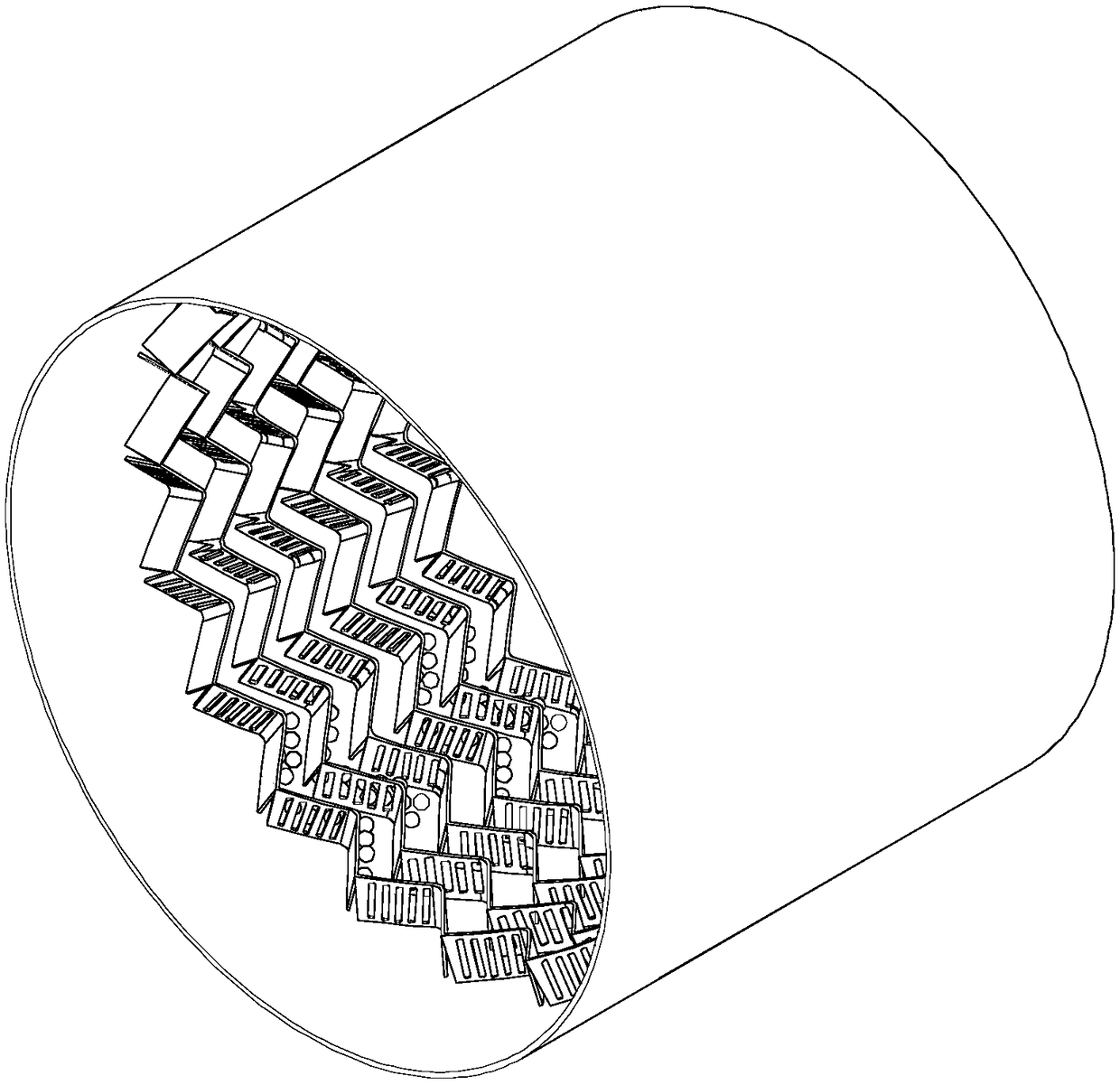

[0037] A complete set of equipment for pyrolysis of solid hazardous waste, comprising an outer cylinder 2 and a rotatable inner cylinder 4. The interior of the inner cylinder 4 is provided with at least one pyrolysis material storage area, and the storage area is formed by a circular ring on the inner wall of the inner cylinder. Several sets of guide plates and baffle plates 21 arranged on the top of the guide plates at both ends are composed, each set of guide plates is composed of alternately connected vertical plates 7 and sieve plates 5, the bottom of the inner cylinder 4 is provided with a reaction medium 22, and between each set of guide plates A reaction medium is also provided, and the reaction medium is a high temperature resistant sphere;

[0038] One side of the outer cylinder 2 is provided with an openable hatch 1, and a hot air cavity is arranged between the outer cylinder 2 and the inner cylinder 4, and a hot air outlet 3 and a hot air inlet 23 are arranged on the...

Embodiment 2

[0050] A complete set of equipment for pyrolysis of solid hazardous waste, including an outer cylinder 2 and a rotatable inner cylinder 4. Inside the inner cylinder 4, there are multiple sets of pyrolysis material placement areas, and each set of pyrolysis material placement areas is provided by the inner wall of the inner cylinder. Several sets of guide plates arranged around the circumference and baffle plates 21 arranged on the top of the guide plates at both ends are formed. Each set of guide plates is composed of alternately connected vertical plates 7 and sieve plates 5. The bottom of the inner cylinder 4 is provided with a reaction medium 22, and each set A reaction medium is also arranged between the guide plates, and the reaction medium is a high temperature resistant sphere;

[0051] One side of the outer cylinder 2 is provided with an openable hatch 1, and a hot air cavity is arranged between the outer cylinder 2 and the inner cylinder 4, and a hot air outlet 3 and a...

Embodiment 3

[0058] A complete set of equipment for pyrolysis of solid hazardous waste, including an outer cylinder 2 and a rotatable inner cylinder 4. Inside the inner cylinder 4, there are multiple sets of pyrolysis material placement areas, and each set of pyrolysis material placement areas is provided by the inner wall of the inner cylinder. Several sets of guide plates arranged around the circumference and baffle plates 21 arranged on the top of the guide plates at both ends are formed. Each set of guide plates is composed of alternately connected vertical plates 7 and sieve plates 5. The bottom of the inner cylinder 4 is provided with a reaction medium 22, and each set A reaction medium is also arranged between the guide plates, and the reaction medium is a high temperature resistant sphere;

[0059] The vertical plates and sieve plates are arranged alternately between two adjacent sets of guide plates, that is, one set of adjacent two sets of guide plates at the same horizontal posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com