Bridge type shield construction method for box type bridge

A construction method and technology for bridges, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as inability to meet traffic needs, and achieve the effect of reducing operation time and safety risks, good operation stability, and improving speed limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

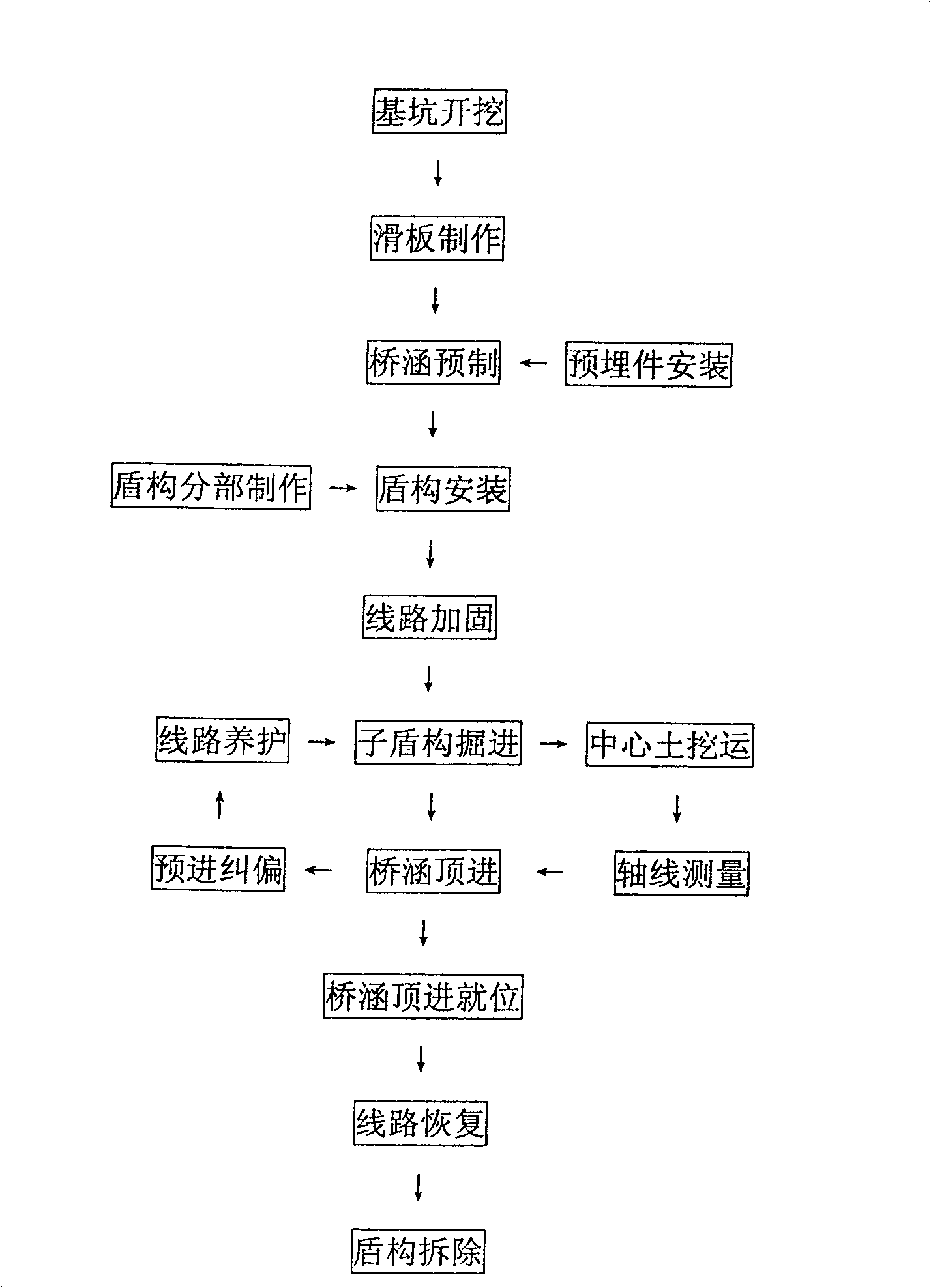

Method used

Image

Examples

Embodiment 1

[0026] Lincun 2-13m Rigid Bridge Project of Guangzhou-Shenzhen Line

[0027]It is designed as a 2-hole rigid bridge with a clearance of 13.03×6m, a length of 14m, a bridge spacing of 5m, and 0.9m from the top of the rail to the top of the culvert, passing through two high-speed seamless main lines underneath. The box-shaped bridge is prefabricated in a single section and constructed by the bridge shield method. During the jacking period, the line is only simply buckled with rails, and there is no digging pile to lift the beam. During the jacking period, the train running speed is limited to 60Km / h to 80km / h. The newly erected bridge has been jacked in place, the south bridge is 6cm lower than the design elevation, and the north bridge is 4cm higher than the design elevation.

Embodiment 2

[0029] 2-8m+2-12m just erected bridge to pass through Beijing-Zhuhai Expressway

[0030] The project is located on Renmin East Road, Changsha City, with a 72° oblique intersection. The foundation is loamy soil with a bearing capacity of 160kpa and no groundwater. The bridges are all 35m long, and the box-shaped bridges are divided into three prefabricated sections. The bridge shield method and the relay method are jacking construction. During the construction period, the speed of vehicles is not limited, and the jacking quality is excellent. The original construction unit used the tube shed method to support and jack the project, the road surface was seriously damaged, and the box bridge was pulled out after the head was planted, and the bridge shield method was used to complete it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com