Template support system of box type girder cast-in-place concrete floor plate of steel frame construction

A technology of formwork support and box girder, which is applied to the preparation of building components on site, formwork/formwork/work frame, building construction, etc., can solve the problems of slowing down construction progress, slow construction progress, and large steel consumption. Achieve the effect of speeding up the construction progress and reducing the workload on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

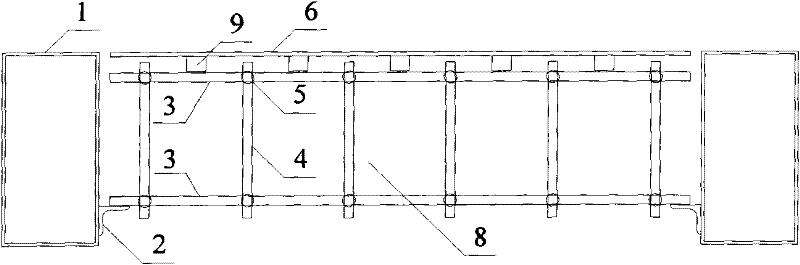

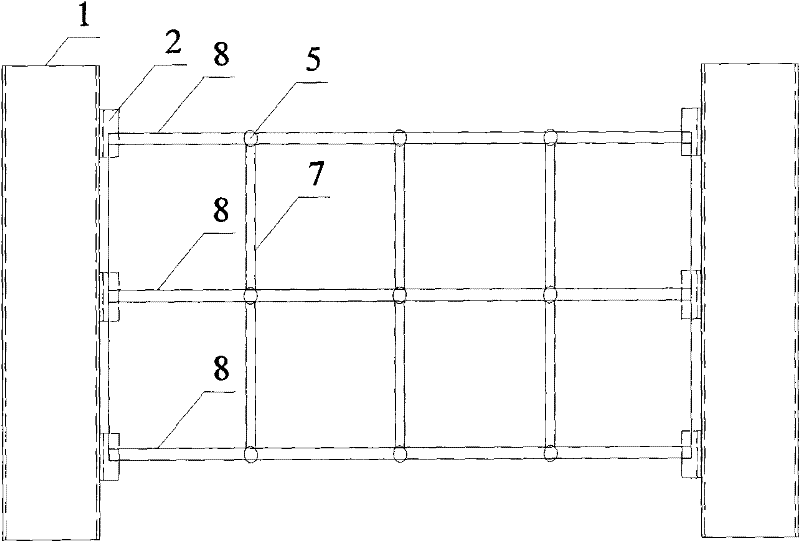

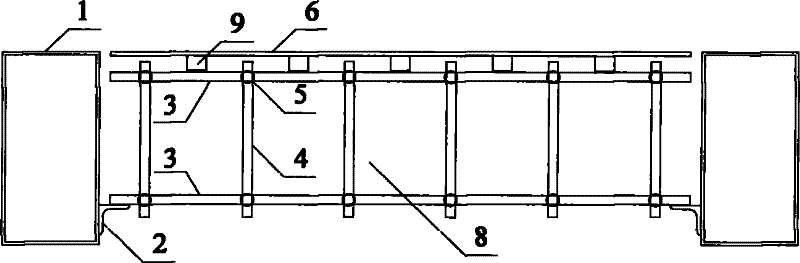

[0018] The formwork support system of the steel frame structure box girder cast-in-place concrete floor includes box section beam 1, corbel 2, horizontal scaffold steel pipe 3, vertical scaffold steel pipe 4, steel pipe fastener 5, wooden formwork 6, tie rod steel pipe 7, Lumber 9; 2 horizontal scaffold steel pipes 3 and multiple vertical scaffold steel pipes 4 are connected through steel pipe fasteners 5 to form a scaffold steel pipe truss 8, more than 2 scaffold steel pipe trusses 8 and more than 2 tie rod steel pipes 7 pass through steel pipe fasteners 5 Connection, the corbel 2 is welded to the box-section beam 1, the lower end of the scaffold steel pipe truss 8 is placed on the corbel 2, the upper end of the scaffold steel pipe truss 8 is placed on the corrugated wood 9, and the wooden formwork 6 is placed on the corrugated wood 9, and the corbel 2 is 100×10 Angle steel with a length of 200 mm, the length of the welds between the back and shoulder of the corbel 2 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com