Elevation type triaxial connecting system for jet printing

A three-axis linkage, lifting mechanism technology, applied in printing, manipulators, typewriters, etc., can solve the problems of small starting torque inertia, narrow speed regulation range, low sensitivity, etc., and achieve good stability, simple control structure, and clear characters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

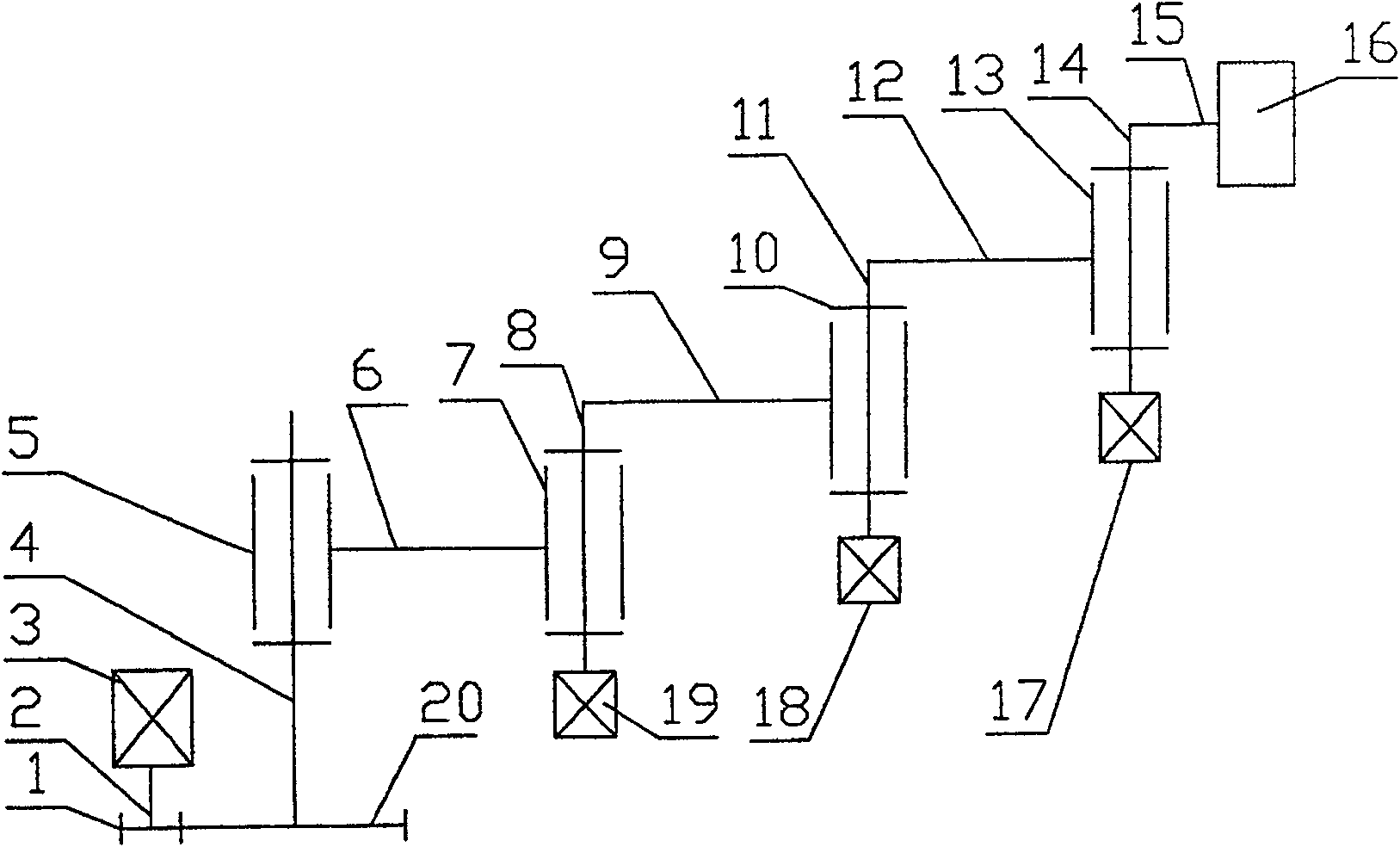

[0025] based on the following figure 1 with figure 2 , illustrating a preferred embodiment of the present invention.

[0026] Such as figure 1 As shown, the lift-type three-axis linkage mechanism for jet printing provided by the present invention includes a plane mechanism and a lift mechanism;

[0027] The planar mechanism is provided with a mechanical arm device including three rotational degrees of freedom around the respective Z axes and a wrist device connected to the printing device;

[0028] Described lifting mechanism is provided with and comprises servomotor a 19, screw mandrel 4 (ball screw can be used), bull gear 20, pinion 1 and lifting frame 5, and screw mandrel 4 is installed on lifting frame 5, and bull gear 20 and the screw are connected as one, the large gear and the pinion 1 mesh, the pinion 1 is connected with the output shaft 2 of the servo motor, the AC servo motor 19 drives the pinion 1 to realize the main rotation, and the large gear 20 and the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com