Active organic electroluminescent display panel and production thereof

A technology of electroluminescence display and manufacturing method, which is applied in the direction of electroluminescence light source, light source, electric light source, etc., to achieve the effect of improving brightness difference, uniform brightness, and improving display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

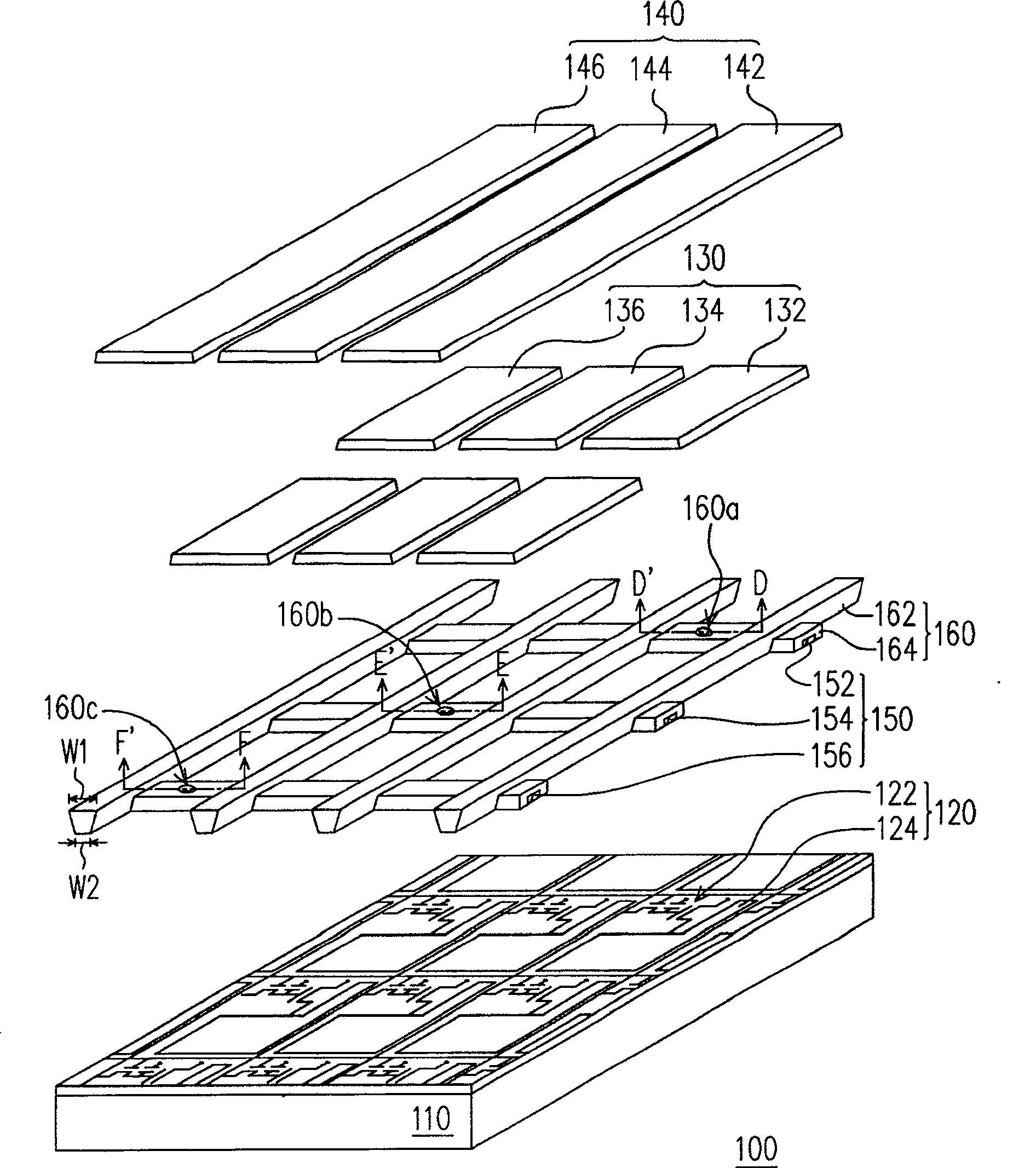

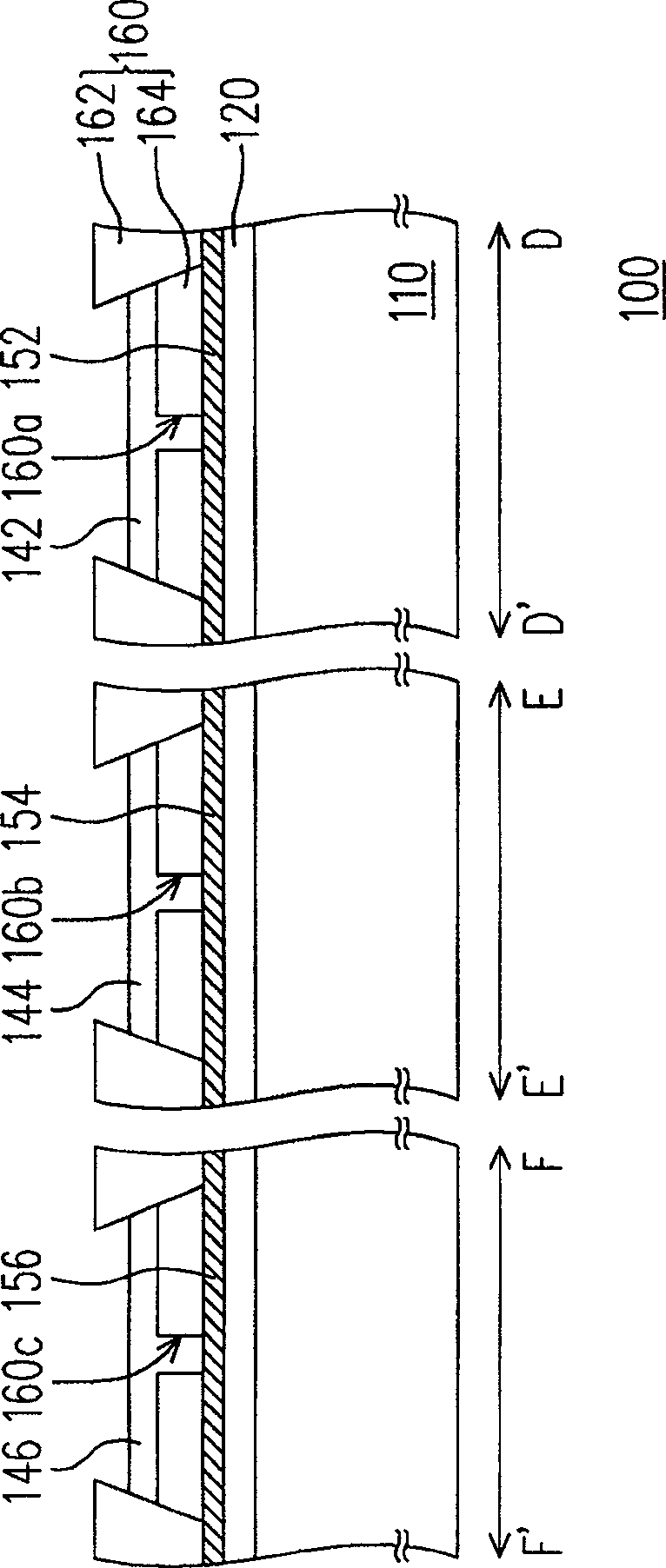

[0059] see Figure 1A and Figure 1B as shown, Figure 1A It is a structural schematic diagram of an active organic electroluminescence display panel according to a first preferred embodiment of the present invention. Figure 1Bis a schematic diagram of a partial cross-sectional structure of an active organic electroluminescence display panel according to a first preferred embodiment of the present invention, wherein Figure 1B The cross-sectional structure shown is along the Figure 1A D-D', E-E' and F-F' section lines. Please also see Figure 1A and Figure 1B The active organic electroluminescence display panel 100 includes a substrate 110 , a pixel structure layer 120 , an organic light emitting layer 130 and a cathode pattern layer 140 , wherein the pixel structure layer 120 is disposed on the substrate 110 . In addition, the pixel structure layer 120 includes, for example, an active element array 122 and an anode pattern layer 124, wherein the active element array 122 ...

no. 2 example

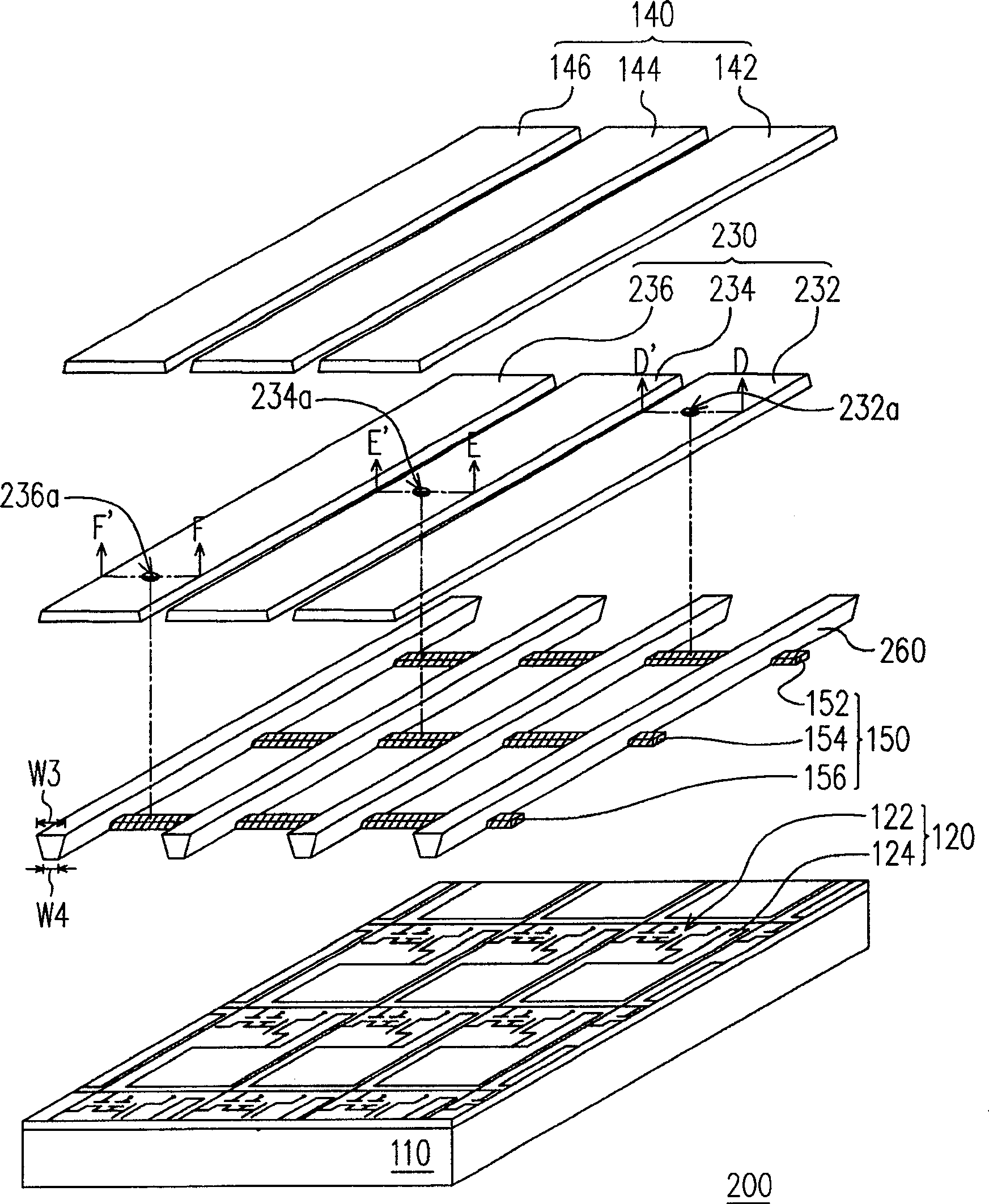

[0068] see Figure 2A and Figure 2B as shown, Figure 2A It is a schematic structural diagram of an active organic electroluminescence display panel according to a second preferred embodiment of the present invention. Figure 2B is a schematic diagram of a partial cross-sectional structure of an active organic electroluminescence display panel according to a second preferred embodiment of the present invention, wherein Figure 2B The cross-sectional structure shown is along the Figure 2A D-D', E-E' and F-F' section lines. If the number of the second embodiment is the same as that of the first embodiment, it means that the components specified in the second embodiment are the same as those specified in the first embodiment, and will not be repeated here.

[0069] see Figure 2A and Figure 2B As shown, the second embodiment is similar to the first embodiment, the difference is that the shapes of the first organic light emitting pattern 132, the second organic light emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com