Full-automatic cover making machine

A cover machine, fully automatic technology, applied in the field of cardboard positioning, folding machine equipment, paper product gluing, can solve the problem that the qualified rate of finished products cannot be effectively guaranteed, the lack of automatic trimming and corner trimming mechanism, adjustment cumbersome and other problems, to achieve the effect of convenient operation, beautiful finished product, simple and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

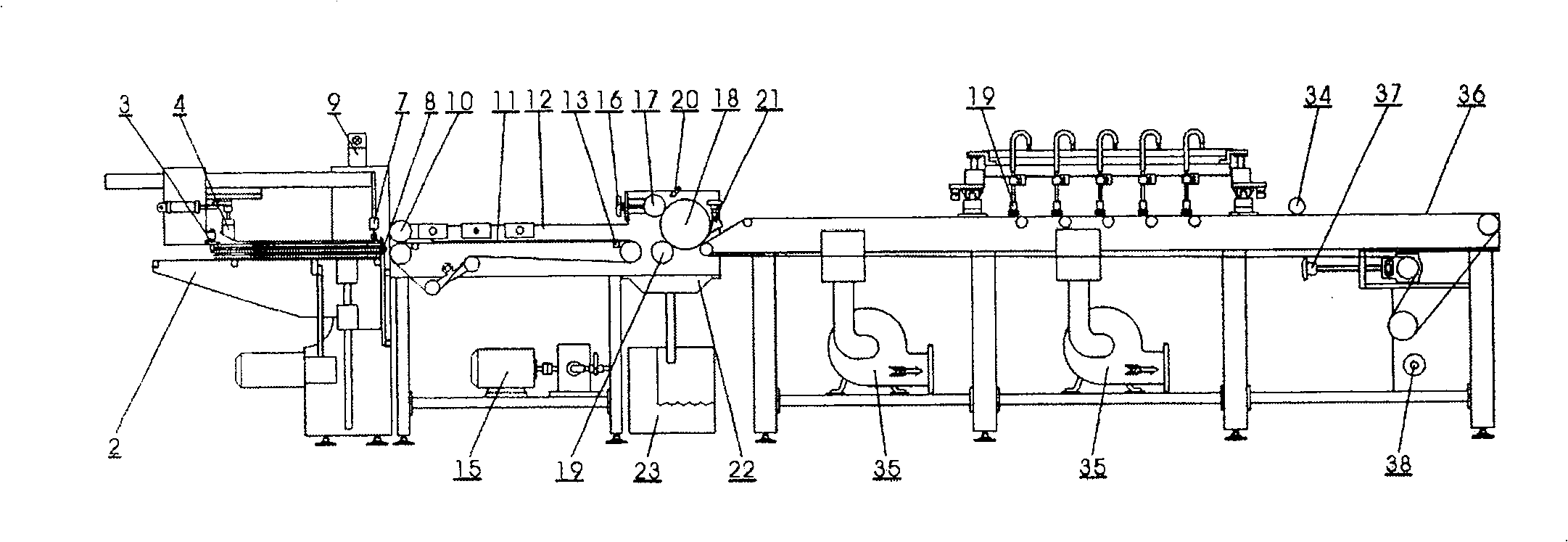

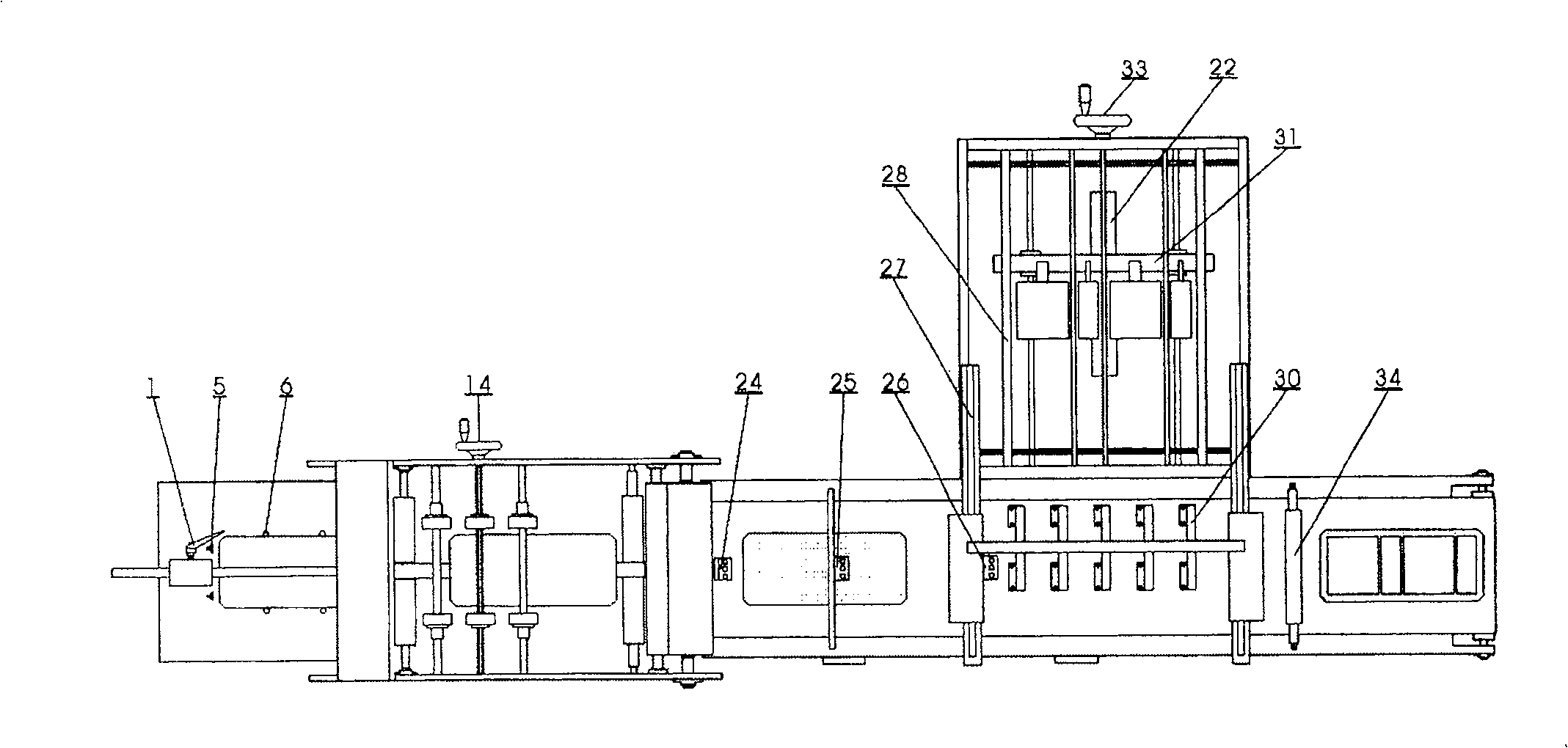

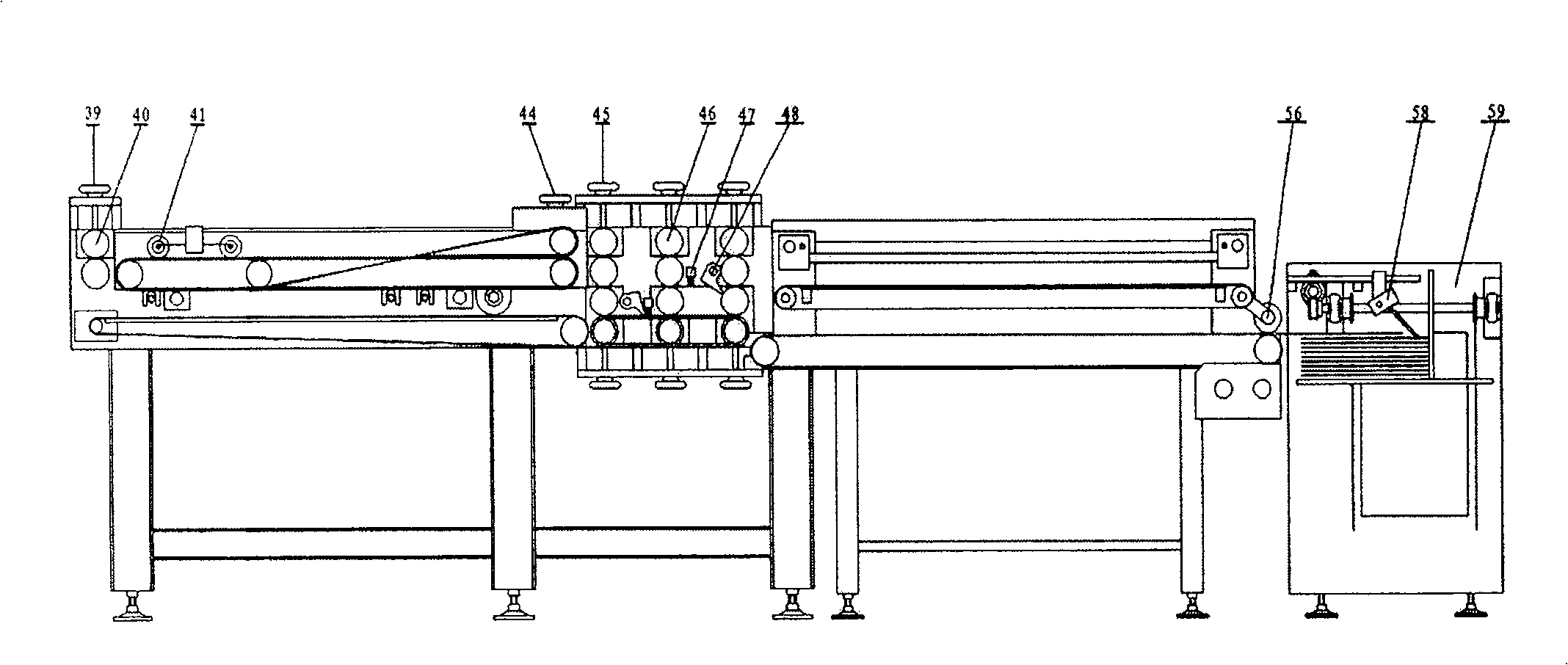

[0017] The fully automatic cover folding machine consists of a gluing part, a cardboard positioning part, a folding part and a receiving table. The structure of the gluing part is as follows figure 1 , figure 2 As shown, it includes the stacking platform, paper feeding platform, gluing mechanism and cardboard feeding platform connected in sequence. The feeder head on the stacking platform adopts a fully pneumatically controlled push-back paper feeding structure, that is, there are air blowing nozzles 5 on both sides of the horizontal cylinder 60 of the feeder, and the vertical cylinder 61 and the suction nozzle 4 above the paper 62 connection, the horizontal cylinder 60 is connected with the fixed frame of the vertical cylinder 61, and the adjustment handle 1 adjusts the position of the feeder head according to the length of the paper; the blowing nozzle 5 is used to blow the paper loose so that the paper does not stick; The front end is flat, and the signal lamp 9 flashes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com