Substrate processing method, substrate processing apparatus and control program

A substrate processing method and a substrate processing device technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as narrow process window, complex conveying mechanism, and multi-process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0161] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each figure, the same code|symbol or a similar code|symbol is attached|subjected to the same or equivalent member, and a repeated description is abbreviate|omitted.

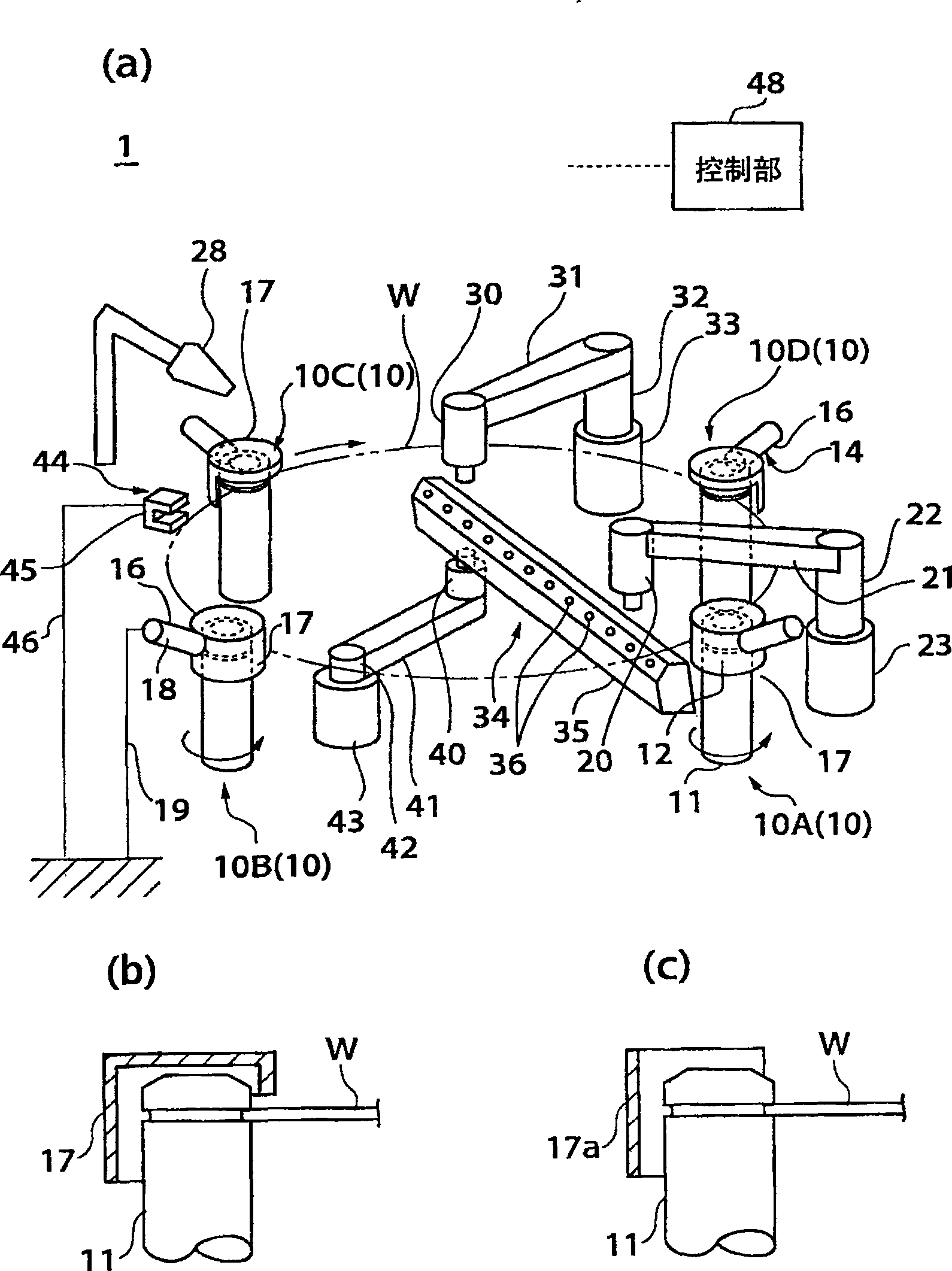

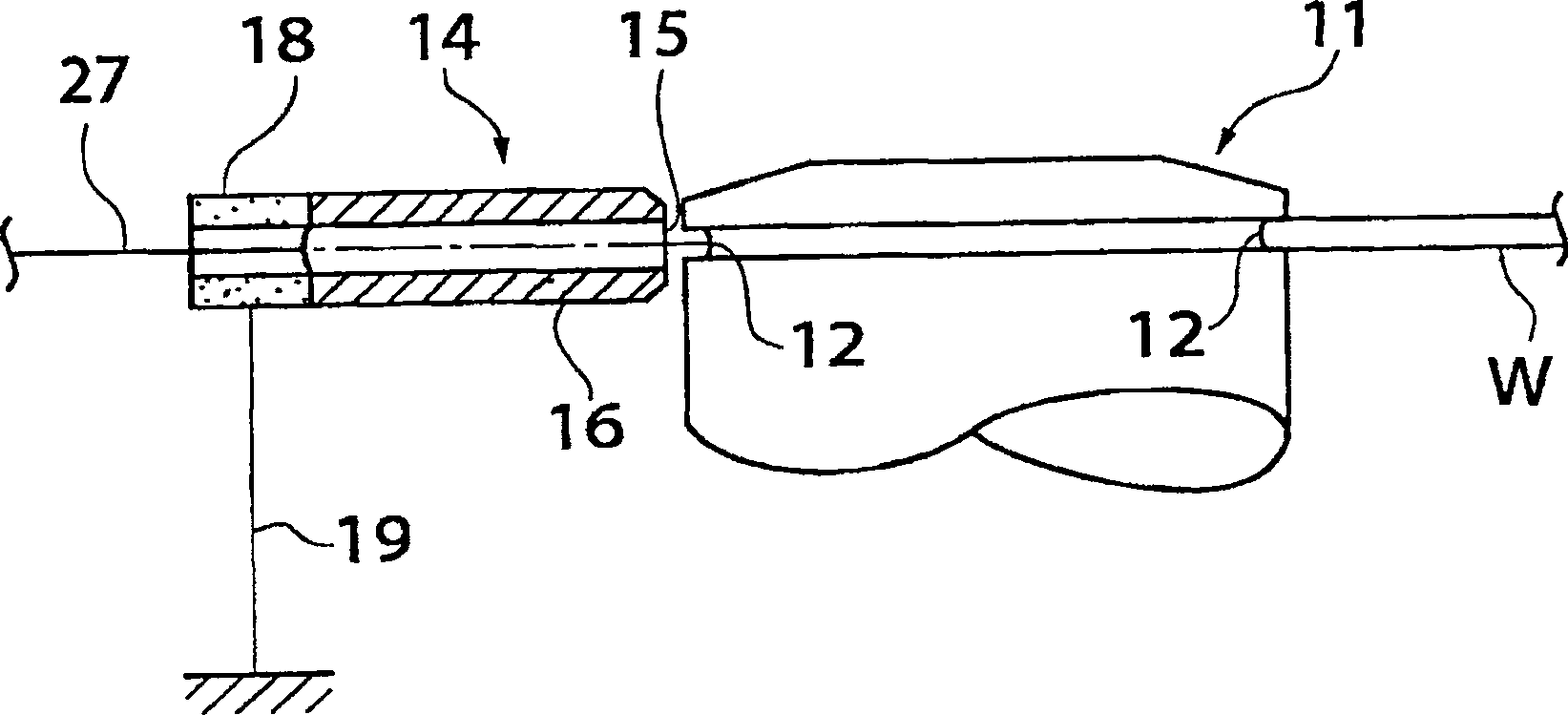

[0162] figure 1 (a) is a schematic perspective view of the substrate processing apparatus 1 according to the embodiment of the present invention. The substrate processing apparatus 1 includes a holding substrate W (in figure 1 In (a), the substrate holder 10 rotates and is shown by a two-dot chain line, the water supply nozzle 20 for supplying cleaning water to the upper surface of the substrate W, and the upper surface fixed rinse nozzle 28 serving as a rinse water supply nozzle , the upper air supply nozzle 30 for supplying drying gas to the upper surface of the substrate W, the lower surface porous rinse nozzle 34 serving as a rinse water supply nozzle for supplying cleaning water to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com