Single chip integrated CMOS imaging sensor with dual-focus microlens array

A microlens array, image sensor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of quantum efficiency, light concentration efficiency and poor reliability, moisture resistance, high temperature resistance and radiation resistance. Aging and other issues to achieve the effect of improving light collection and quantum efficiency, low cost, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings.

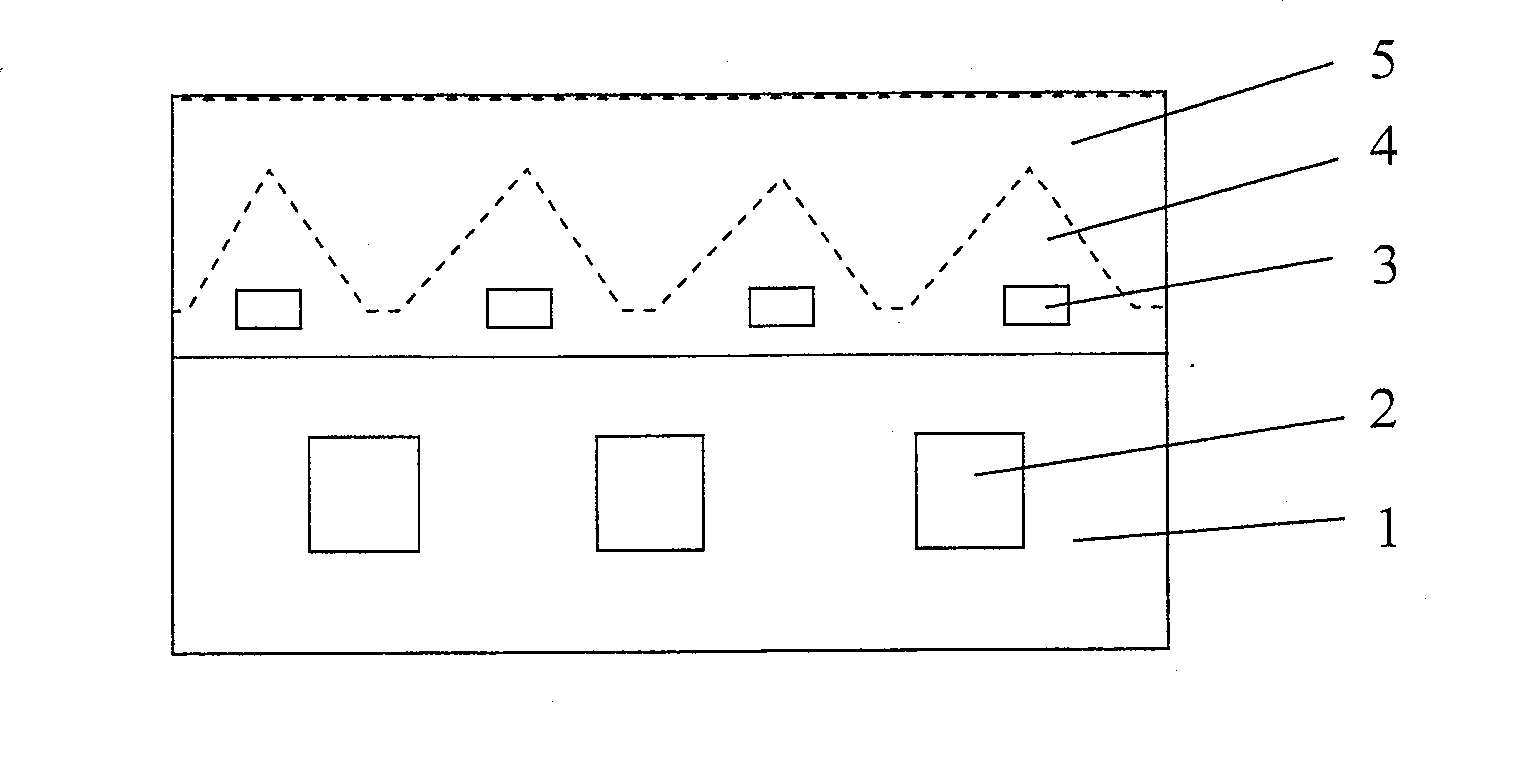

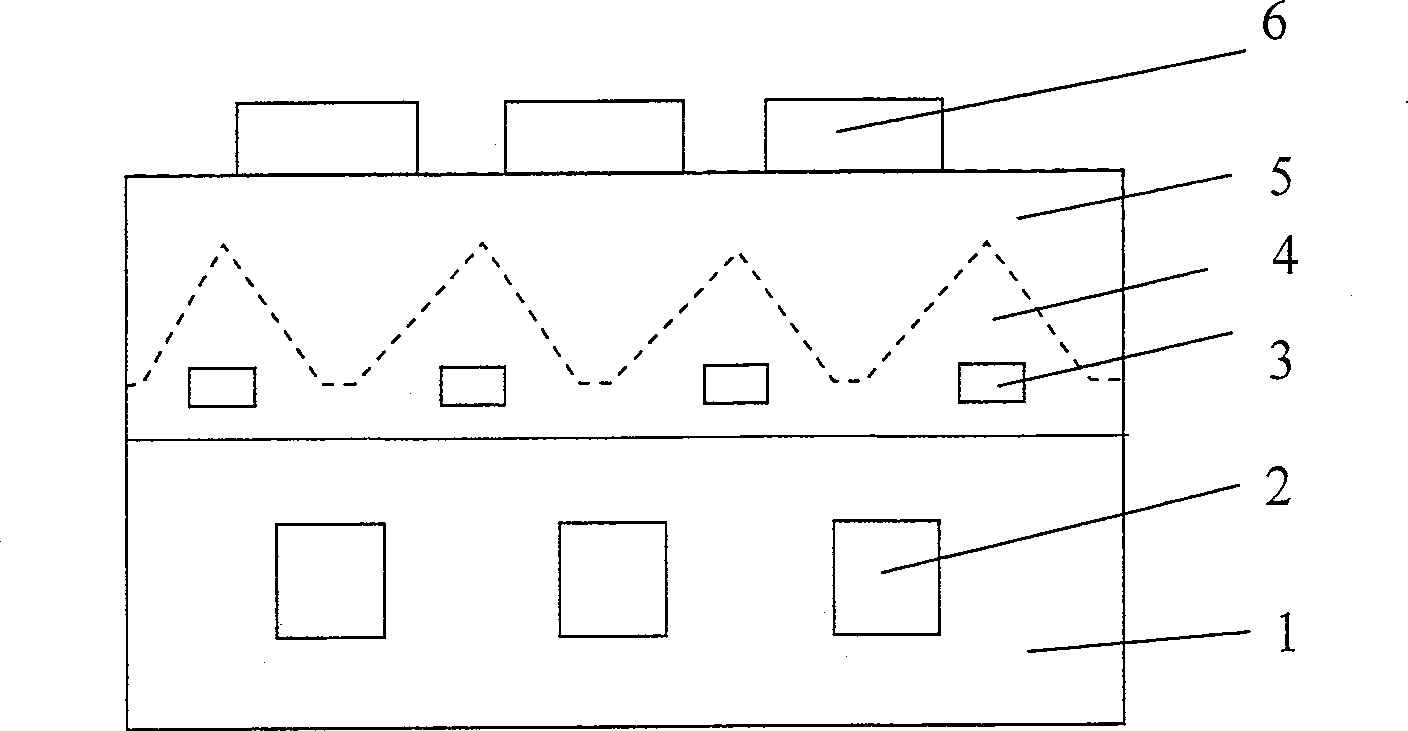

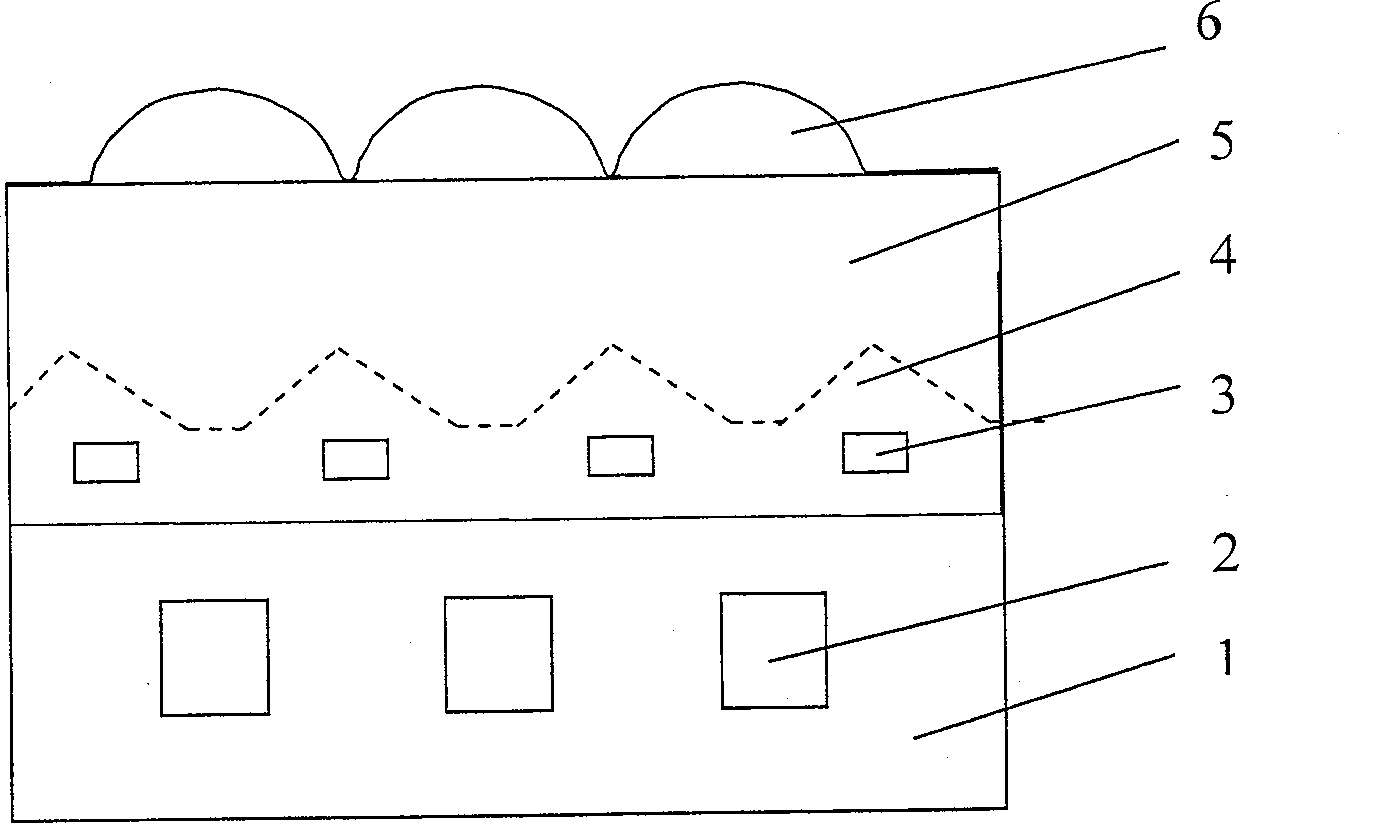

[0058] Figure 1A-1E A schematic diagram of the monolithically integrated CMOS image sensor with a bifocal lens array and its manufacturing process of the present invention is illustrated.

[0059] According to a specific embodiment of the present invention, the monolithically integrated CMOS image sensor with bifocal microlens array, such as Figure 1E shown, including:

[0060] A standard CMOS logic circuit, which integrates a pin photodiode 2, has a top layer metal 3, and a silicon oxide insulating layer 4;

[0061] The microlens array 5 is integrated in the active area of the CMOS circuit, more specifically, the light-absorbing surface corresponding to the pixel unit;

[0062] A silicon nitride layer 7 covering the microlens array 5;

[0063] The color filter 8 is arranged on the silicon nitride layer 7;

[0064] Among them, the bifocal microlens array is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com