Exhaust gas treatment system

A technology for waste gas treatment and waste gas, which is applied to the treatment of combustion products, combustion methods, and the use of liquid separation agents, etc. It can solve the problems of easy accumulation and blockage of dust particles, affecting equipment use time and human resources, and the failure of the treatment system to process waste gas normally. , to achieve the effect of convenient cleaning of the combustion chamber, saving manpower requirements, and improving the accumulation of dust in the channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

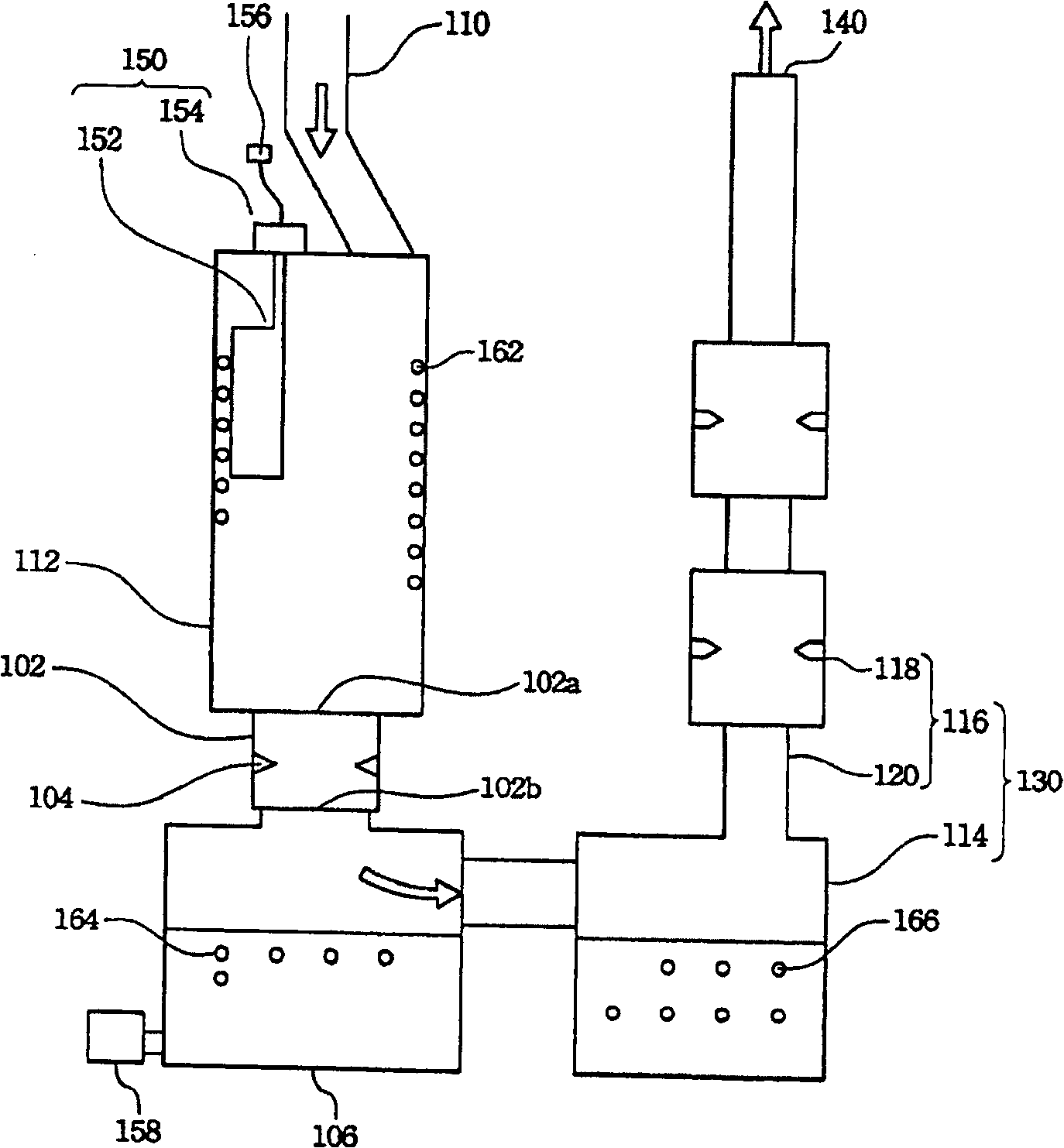

[0027] The invention discloses a waste gas treatment system, which has the effect of improving dust accumulation and blocking in pipelines generated by burning waste gas. By vertically connecting the channel of the combustion gas outlet to a dust collection box, the situation of dust accumulation in the pipeline is greatly reduced or even eliminated, thereby reducing the frequency of equipment cleaning and making it more convenient. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate figure 1 icon.

[0028] refer to figure 1 , which shows a configuration diagram of components of an exhaust gas treatment system according to a preferred embodiment of the present invention. The exhaust gas treatment system mainly includes a guide channel 102 , a fluid nozzle 104 and a dust box 106 . An outlet 102b below the guide channel 102 is vertically connected to the dust box 106. A fluid nozzle 104 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap