Making method of proton exchange film fuel cell electric piling

A fuel cell stack, proton exchange membrane technology, applied in fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve the failure to improve the reaction efficiency, the problem of MEA support, and the failure to improve the volume specific power and other problems, to achieve the effect of improving laser welding efficiency, affecting contact resistance, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

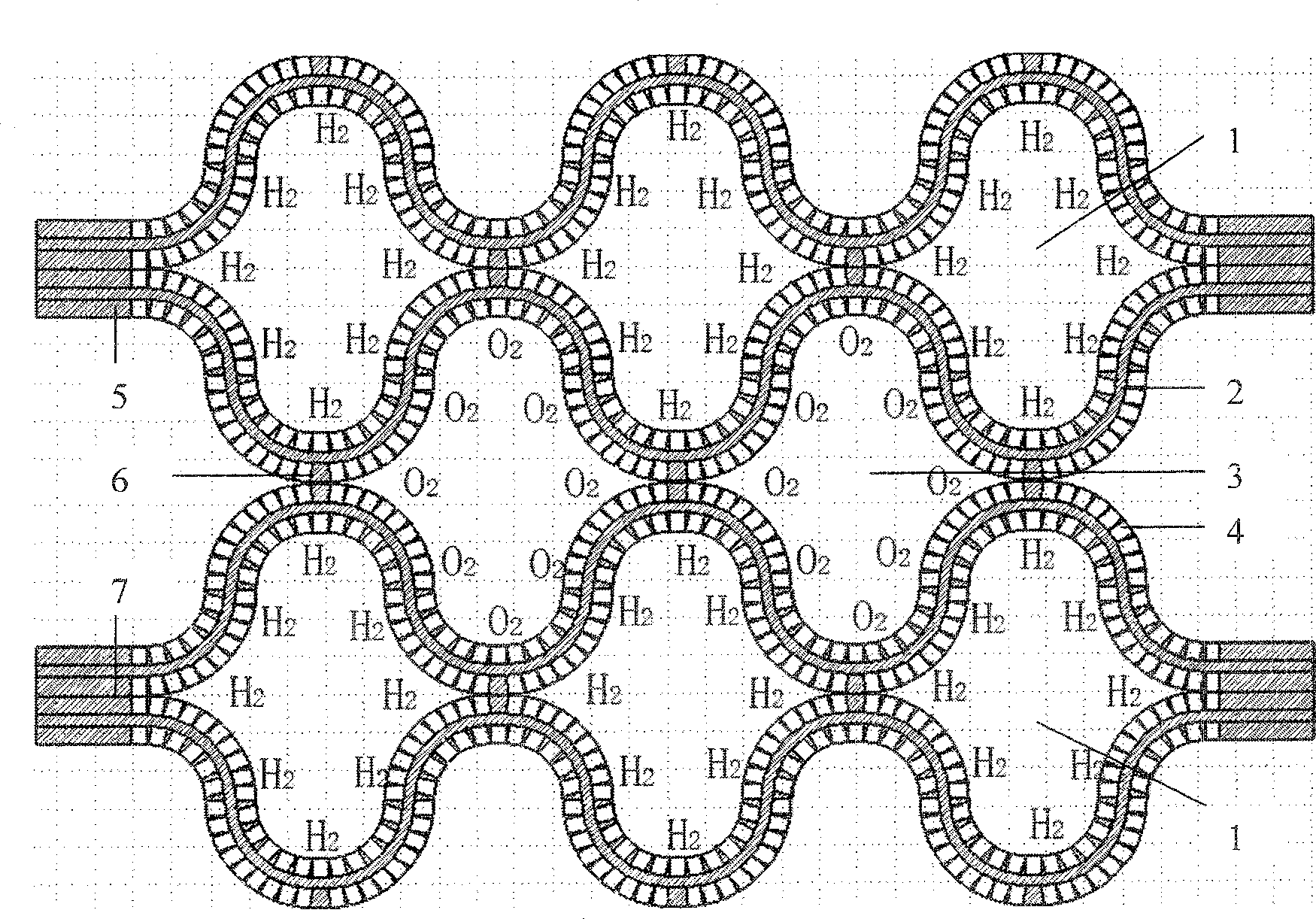

[0035] This embodiment is implemented under the following conditions of implementation and technical requirements:

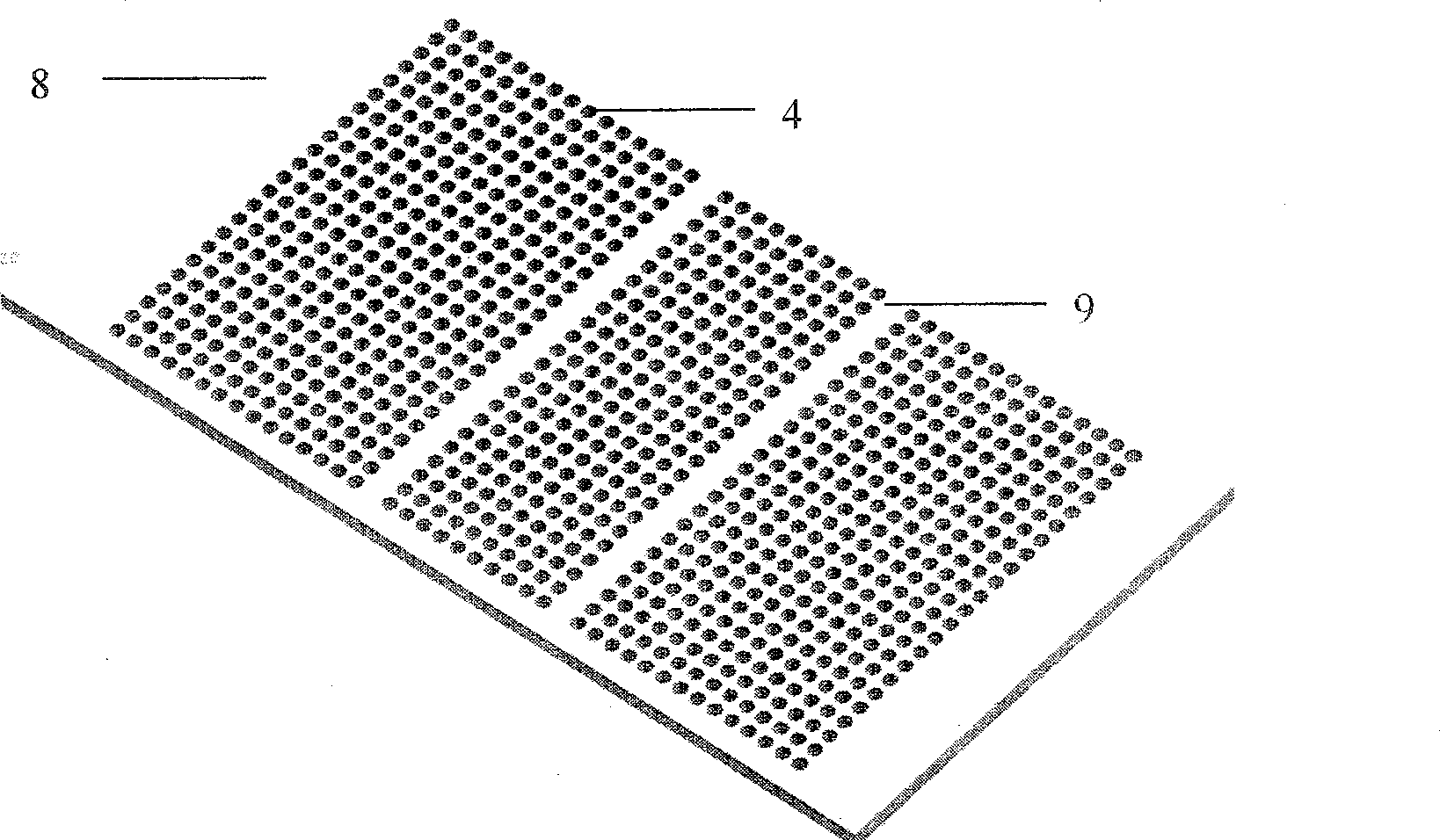

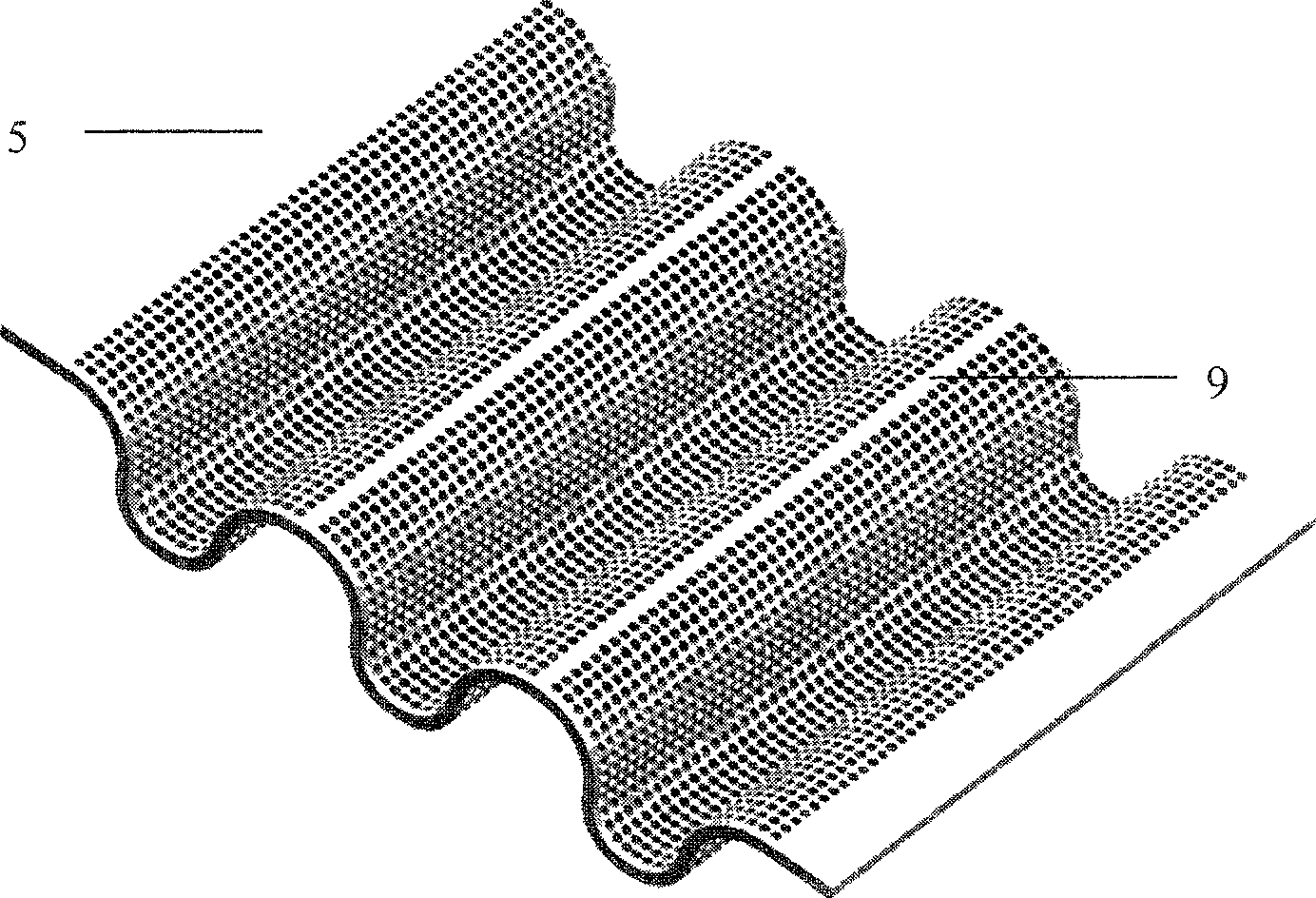

[0036] The corrugated MEA 2 is formed by hot pressing, and the upper and lower dies are made of metal aluminum. When the temperature of the hot pressing process is controlled at 130°C, the overall chemical and physical properties of the MEA will not be affected during bending. The unipolar plate 8 is made of 0.2mm ultra-thin stainless steel, and the dense pores are obtained through a precision punching process with a diameter of 0.4mm. At the same time, a laser welding area 9 is reserved according to the design requirements, and the area width is 0.6mm. Using laser welding technology with concentrated energy and small heat-affected zone, the spot width is 0.4mm, and a pair of unipolar plates are precisely welded into bipolar plates. In this embodiment, a fiber laser is used.

[0037] For the acidic working environment of proton exchange membrane fuel cells, the ...

Embodiment 2

[0041] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0042] The corrugated MEA2 is formed by hot pressing, and the upper and lower dies are made of metal aluminum. When the temperature of the hot pressing process is controlled at 135°C, the overall chemical and physical properties of the MEA will not be affected during bending. The unipolar plate 8 is made of 0.5mm ultra-thin stainless steel, and the dense pores are obtained through a precision punching process with a diameter of 0.8mm. At the same time, a laser welding area 9 is reserved according to the design requirements, and the area width is 1mm. Using laser welding technology with concentrated energy and small heat-affected zone, the beam spot width is 0.6 mm, and a pair of unipolar plates are precisely welded into bipolar plates. In this embodiment, a fiber laser is used.

[0043] This embodiment also adopts cyclic voltammetry, and the electrolyte is a mix...

Embodiment 3

[0047] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0048] The corrugated MEA 2 is formed by hot pressing, and the upper and lower dies are made of metal aluminum. When the temperature of the hot pressing process is controlled at 140°C, the overall chemical and physical properties of the MEA can not be affected during bending. The unipolar plate 8 is made of 1.0mm ultra-thin stainless steel, and the dense pores are obtained through a precision punching process with a diameter of 1mm. At the same time, a laser welding area 9 is reserved according to the design requirements, and the area width is 1.2mm. Using laser welding technology with concentrated energy and small heat-affected zone, the spot width is 0.8mm, and a pair of unipolar plates are precisely welded into a bipolar plate. In this example, a fiber laser is used.

[0049] This embodiment also adopts cyclic voltammetry, and the electrolyte is a mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com