Circulation fluid bed hydrogen preparation reaction technology and reaction device by reforming methane and water steam

A circulating fluidized bed and methane steam technology, applied in the petrochemical field, can solve the problems of increasing market demand, high reaction energy consumption, and high equipment cost, and achieve high equipment cost, simple design structure, and avoid cost increase. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

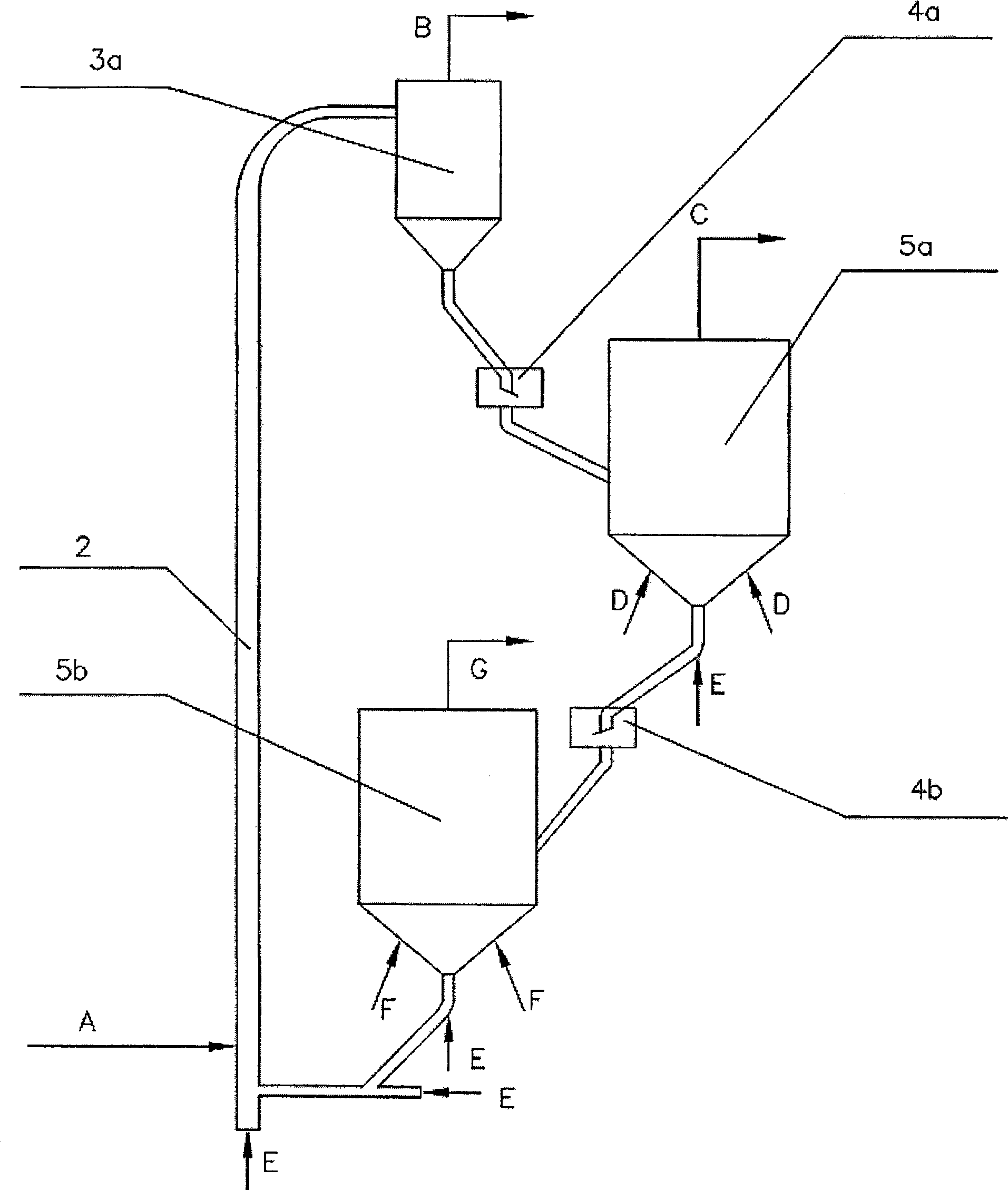

[0032] Such as figure 1 In the shown circulating fluidized bed methane steam reforming reaction device for hydrogen production, feed gas A at 400°C-450°C and catalyst particles at a temperature of 850°C-860°C undergo catalytic reforming reaction in riser reactor 2 , the molar flow rate ratio of water vapor and methane in feed gas A is 1.5, and the total volume flow rate is 9×10 4 m 3 / hr, the superficial gas velocity is 15m / s; the particle size of the catalyst particles is 0.06-0.10mm, and the density is 2200kg / m 3 , the circulation rate is about 700kg / s; the outlet temperature of the catalyst in the riser reactor 2 is 800°C to 810°C, and the methane conversion rate in the reforming process is greater than 95%; the first cyclone separator 3a with a separation efficiency of 98% is used; After leaving the first fluidized bed combustion reactor 5a, the temperature of the catalyst rises to 1190°C-1220°C, and then passes through the second fluidized bed reactor 5b to realize cata...

Embodiment 2

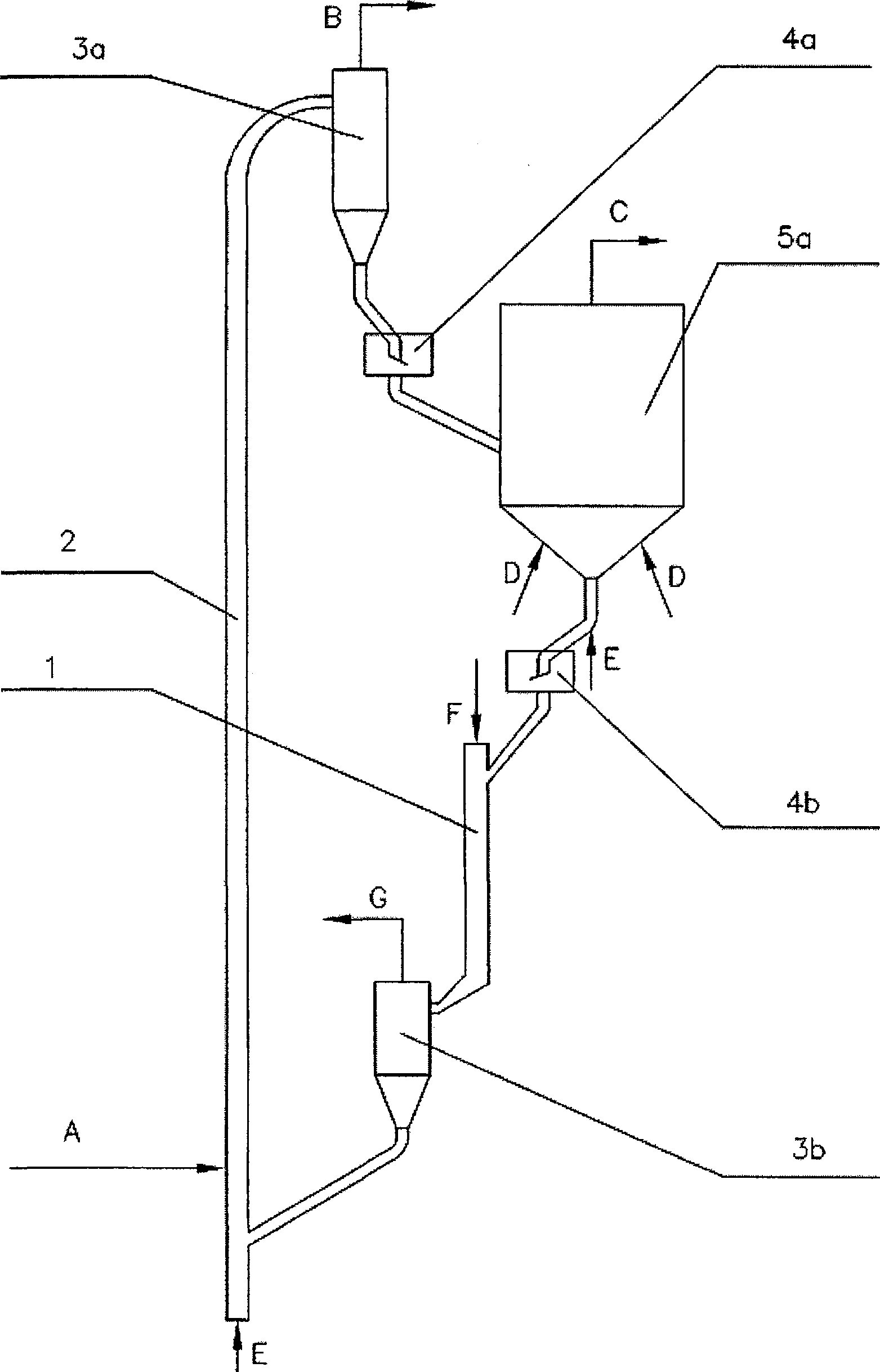

[0034] Such as figure 2 In the shown circulating fluidized bed methane steam reforming reaction device for hydrogen production, feed gas A at 400°C-450°C and catalyst particles at a temperature of 850°C-860°C undergo catalytic reforming reaction in riser reactor 2 , the molar flow rate ratio of water vapor and methane in feed gas A is 1.2, and the total volume flow rate is 7.9×10 4 m 3 / hr, the superficial gas velocity is 13.2m / s; the particle size of the catalyst particles is 0.06-0.10mm, and the density is 2200kg / m 3 , the circulation rate is about 620kg / s; the temperature of the catalyst at the outlet of the riser reactor 2 is 800°C to 805°C, and the methane conversion rate in the reforming process is greater than 95%; the first cyclone separator 3a with a separation efficiency of 98% is used; After the first fluidized bed combustion reactor 5a, the temperature of the catalyst is raised to 1170°C-1190°C, and then the catalyst is regenerated through the downcomer reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com