Electric control gasoline injector

A gasoline injector and electronic control technology, which is applied to machines/engines, fuel injection devices, engine components, etc., can solve the problems of high cost, high processing difficulty, and high processing conditions, and achieves light weight, convenient processing, The effect of processing simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

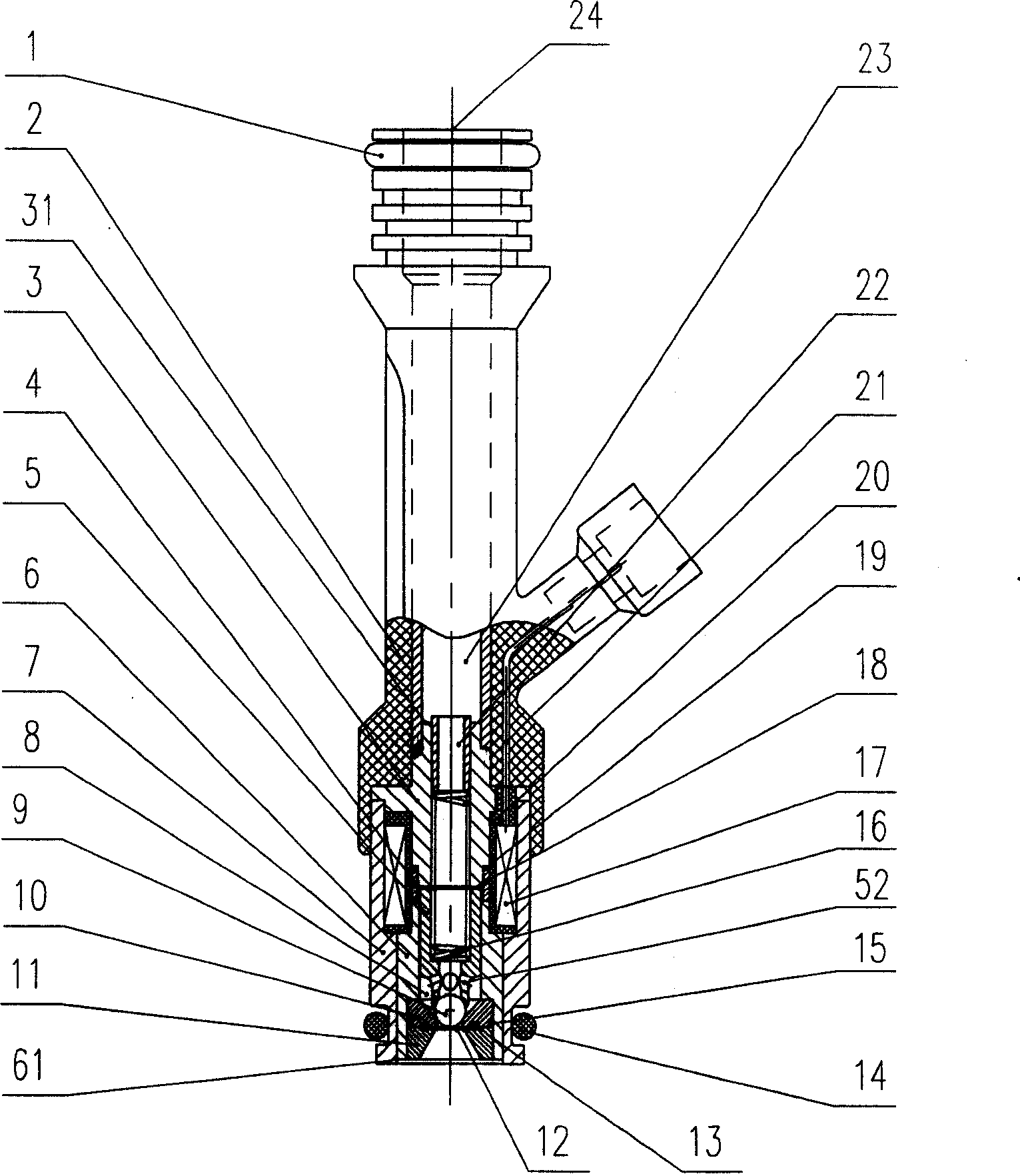

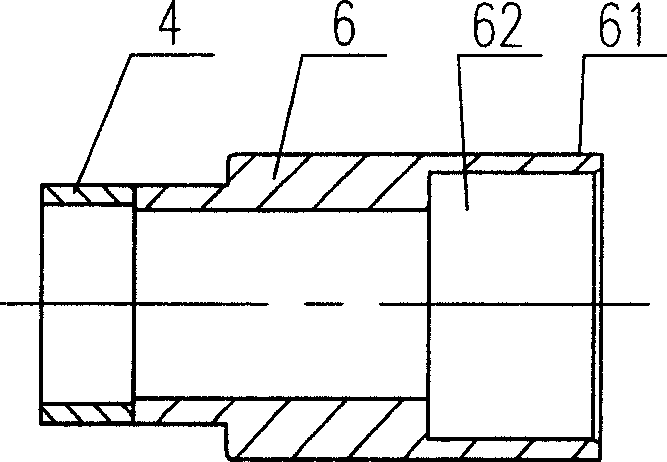

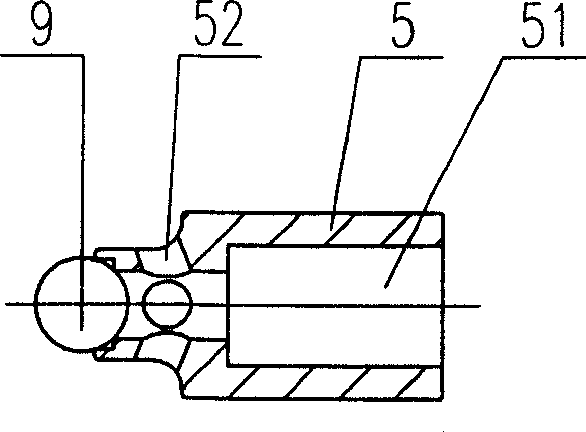

[0038] An electronically controlled gasoline fuel injector, comprising a housing (7), a valve core (5), a metering hole valve seat, an iron core (3), a guide sleeve (6), and an electromagnetic coil (17) with a wire holder (20) , degaussing sheet (18), oil inlet pipe (23), spring (16) and plastic casing (2), and the guide sleeve (6) with the spool (5) inside is mounted on one end of the casing (7), and the spring (16) is installed in the inner hole of the spool (5) and extends into one end of the inner hole of the iron core (3), and one end of the guide sleeve (6) is equipped with the valve seat (10), O-shaped sealing ring II ( 13), O-ring IV (15), orifice plate (12), cover (11) composed of orifice valve seat, coil (17) and iron core ( 3), the inner hole of the iron core (3) with the spring (16) extending into the end is equipped with a hollow opening elastic pin (22), and the elastic pin (22) and the iron core (3) are welded and fixed on the upper end surface (31) of the iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com