Field emitting display of electronic emitting source including forming multilayer structure

An electron emission source and electron emission technology, applied in the direction of image/graphic display tube, discharge tube/lamp manufacturing, discharge tube/lamp parts, etc., can solve the problems of shortened life of electron emission source, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

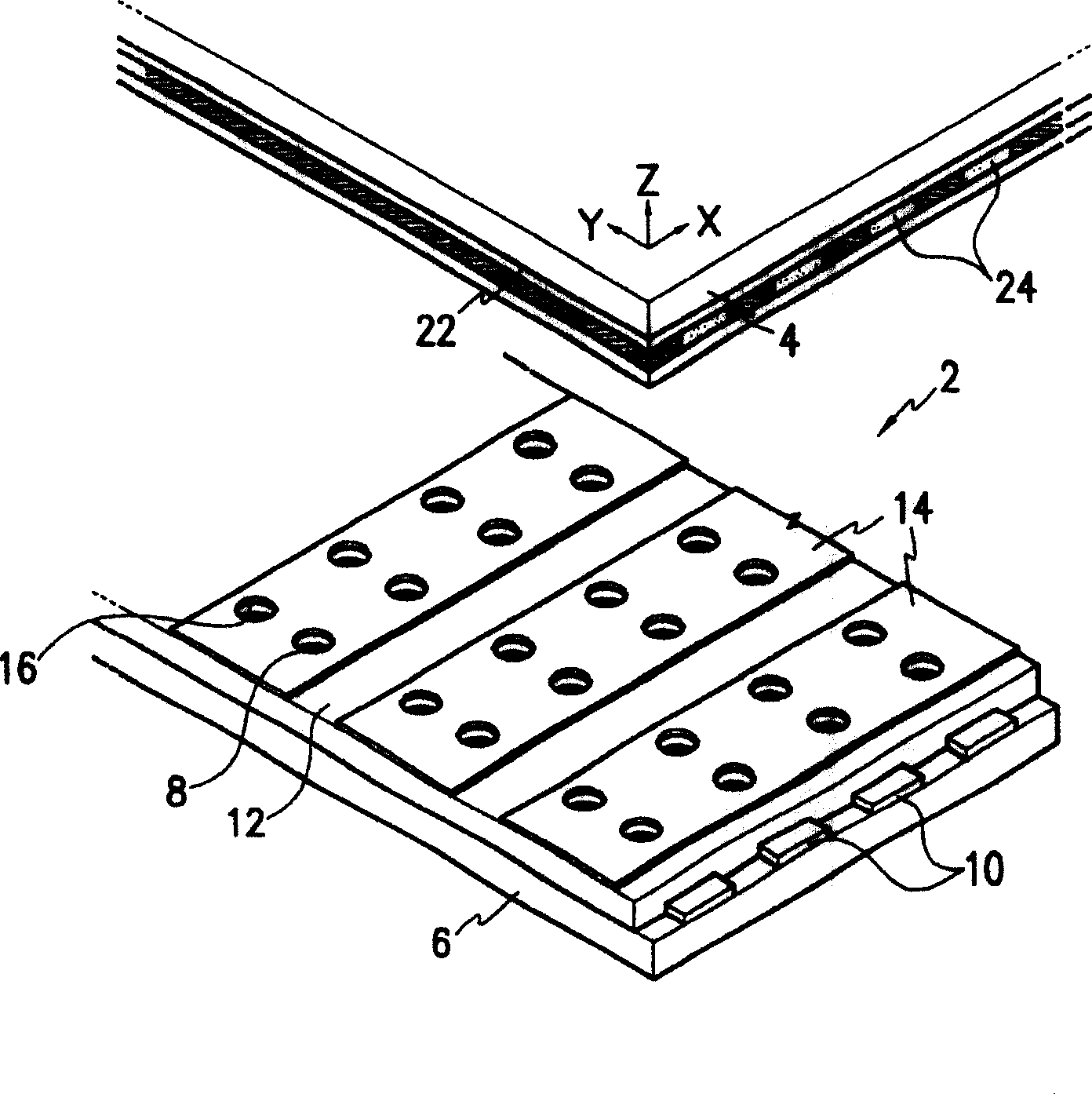

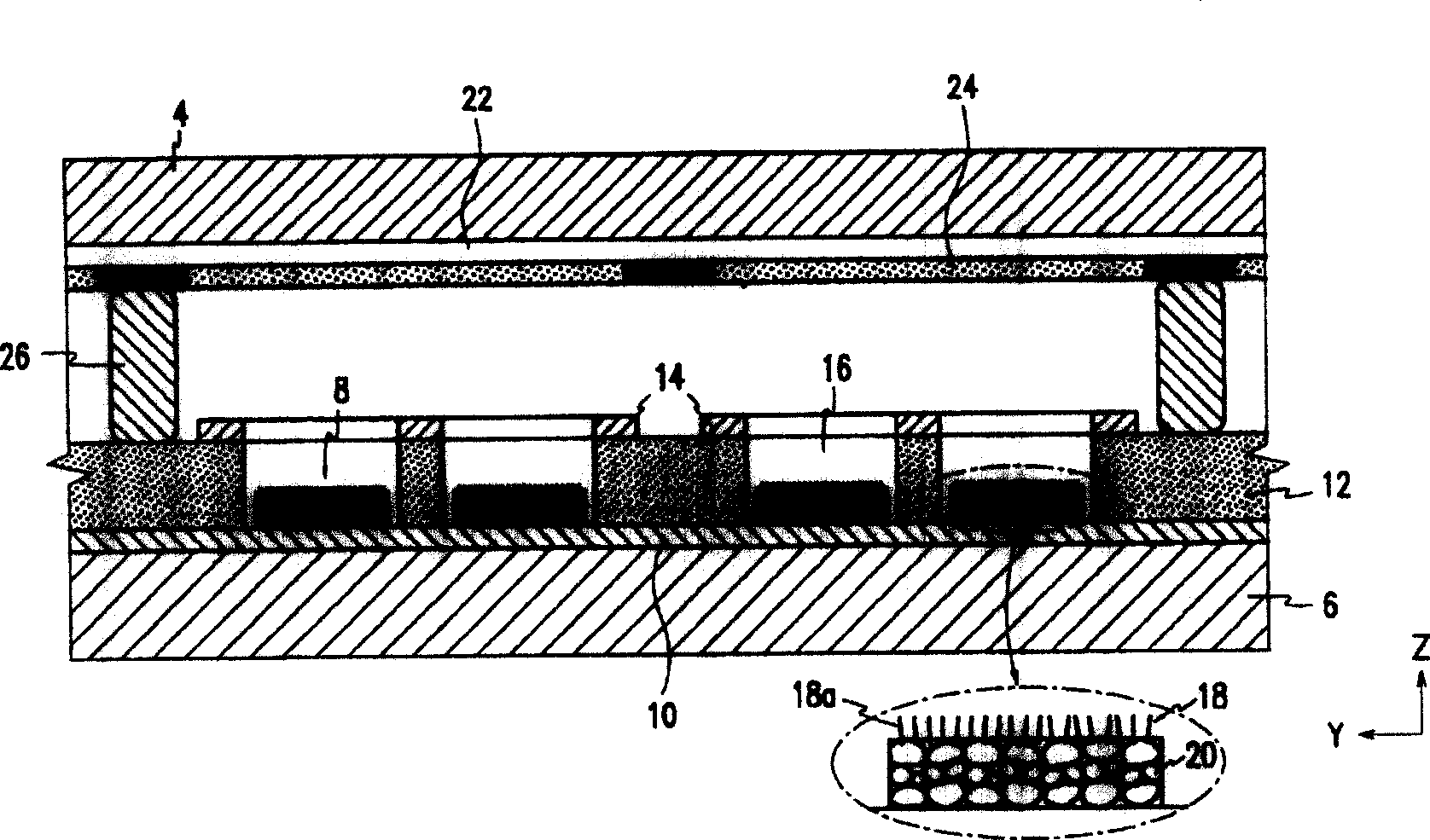

[0031] figure 1 is a partial perspective view of a field emission display according to a first preferred embodiment of the present invention, figure 2 is a partial sectional view of the field emission display according to the first preferred embodiment of the present invention.

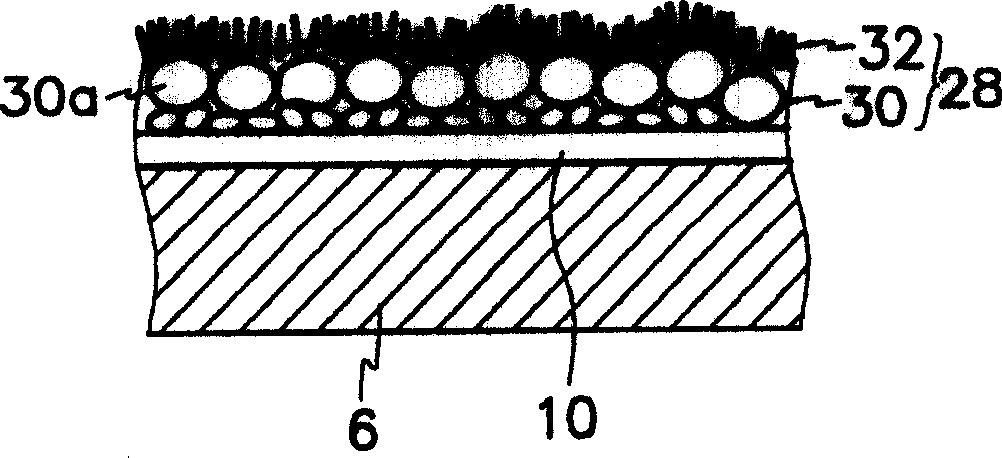

[0032] A field emission display (FED) 2 includes a front substrate 4 and a rear substrate 6 disposed opposite to each other at a predetermined interval to form a vacuum device. An electron emission source 8 and a structure for generating an electric field required for electron emission are disposed on the rear substrate 6 , while a structure capable of realizing a predetermined image by emitting visible light using electrons is disposed on the front substrate 4 .

[0033] More specifically, cathode electrodes 10 are formed in a stripe pattern on the rear substrate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com