Multi-needle embroidering machine

An embroidery machine and multi-head technology, which is applied in the field of structural improvement of multi-head embroidery machines, can solve problems such as insufficient functions of multi-head embroidery machines, poor synchronization of needle bar transmission mechanisms, easy reversal or slipping needles, etc., to achieve easy adjustment and maintenance, Shorten the production cycle, good self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

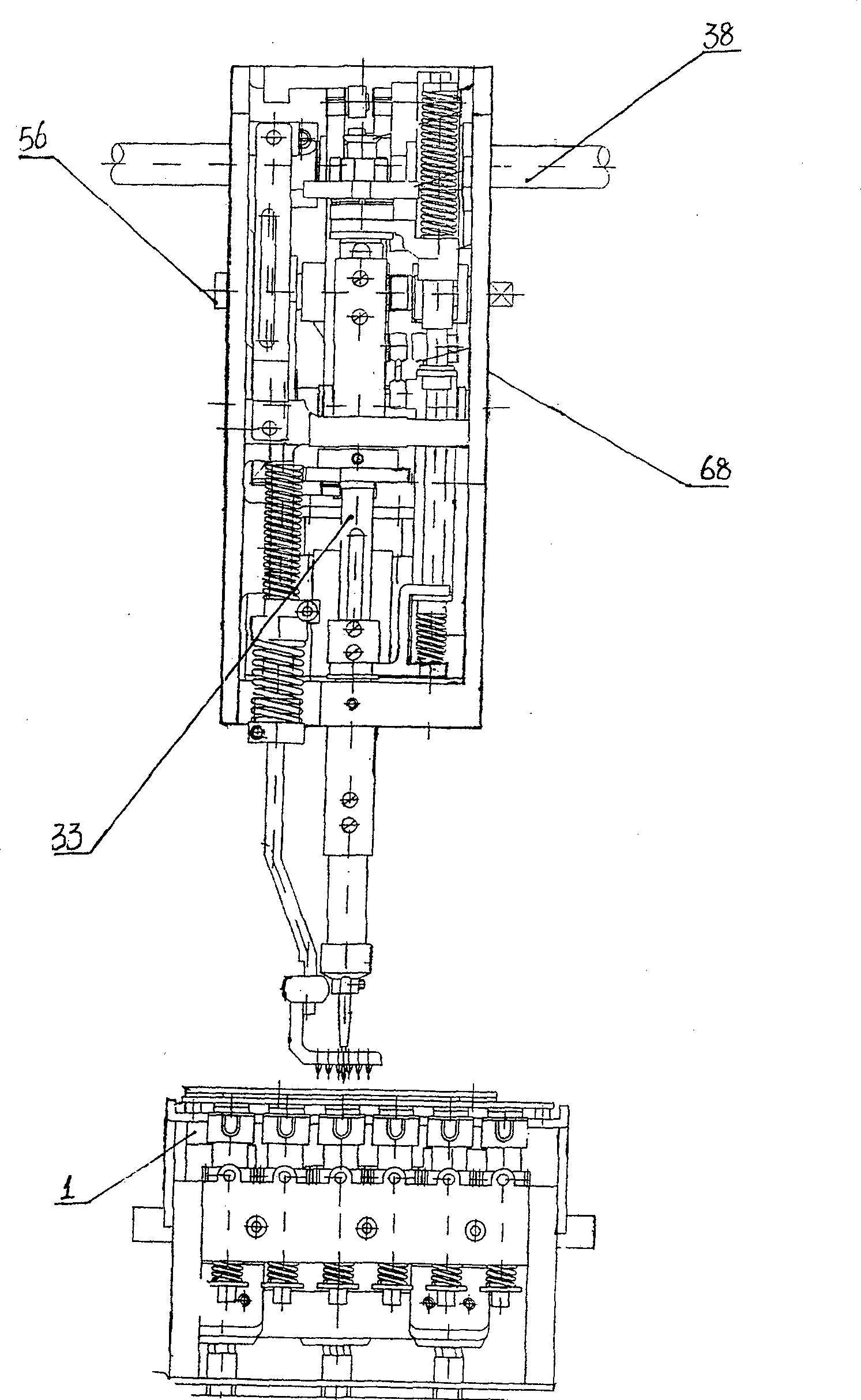

[0024] Embodiment 1: comprise main drive shaft 38, be provided with eight machine heads 68 that link to each other on it, be provided with ring box 1 under the machine head, be provided with driving mechanism on described main drive shaft, described Driving mechanism links to each other with needle bar transmission mechanism, and the other end of needle bar transmission mechanism is provided with needle bar 33, is provided with crochet needle; Be provided with needle bar drive gear 34 on needle bar; There is a ring mechanism.

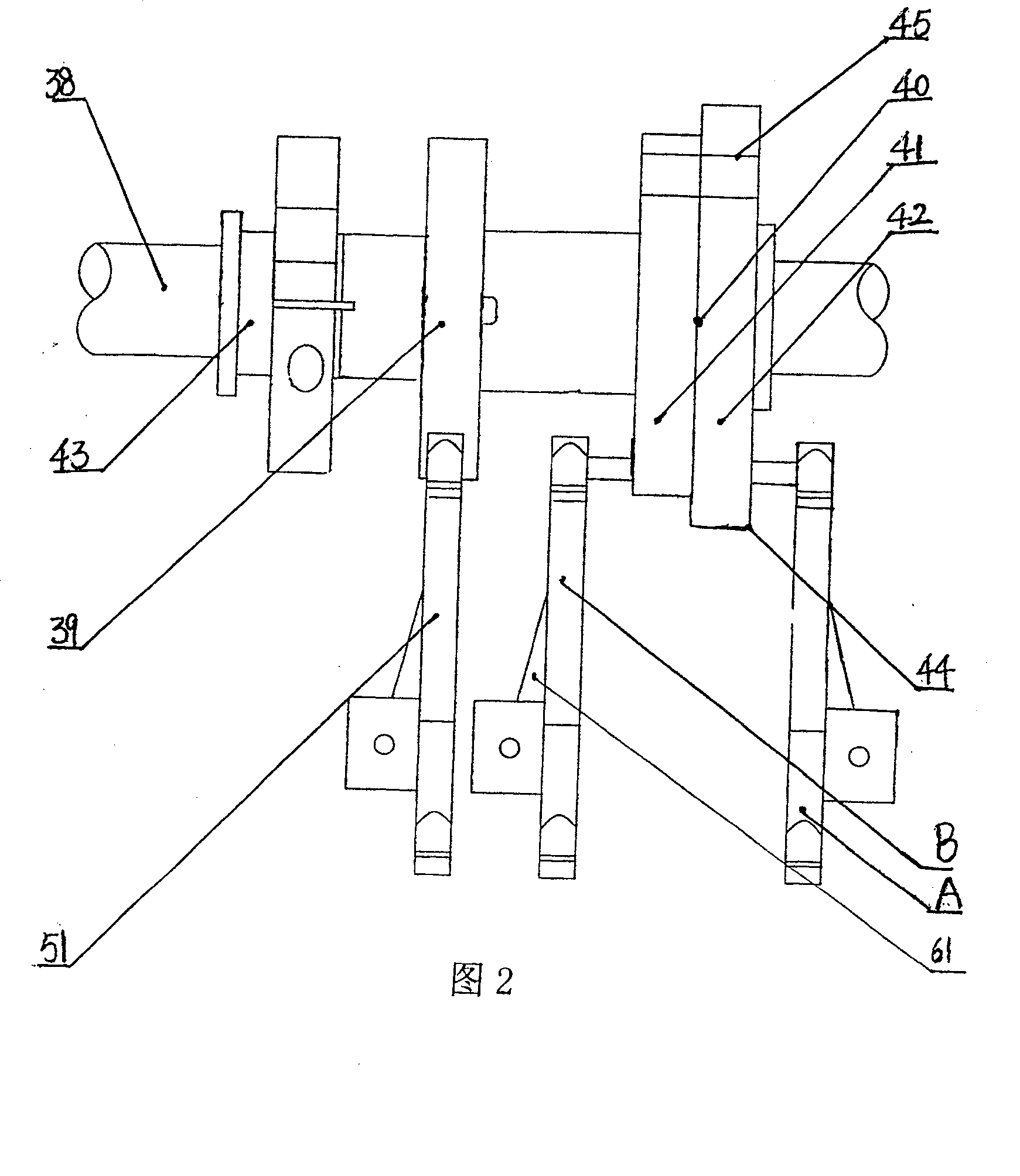

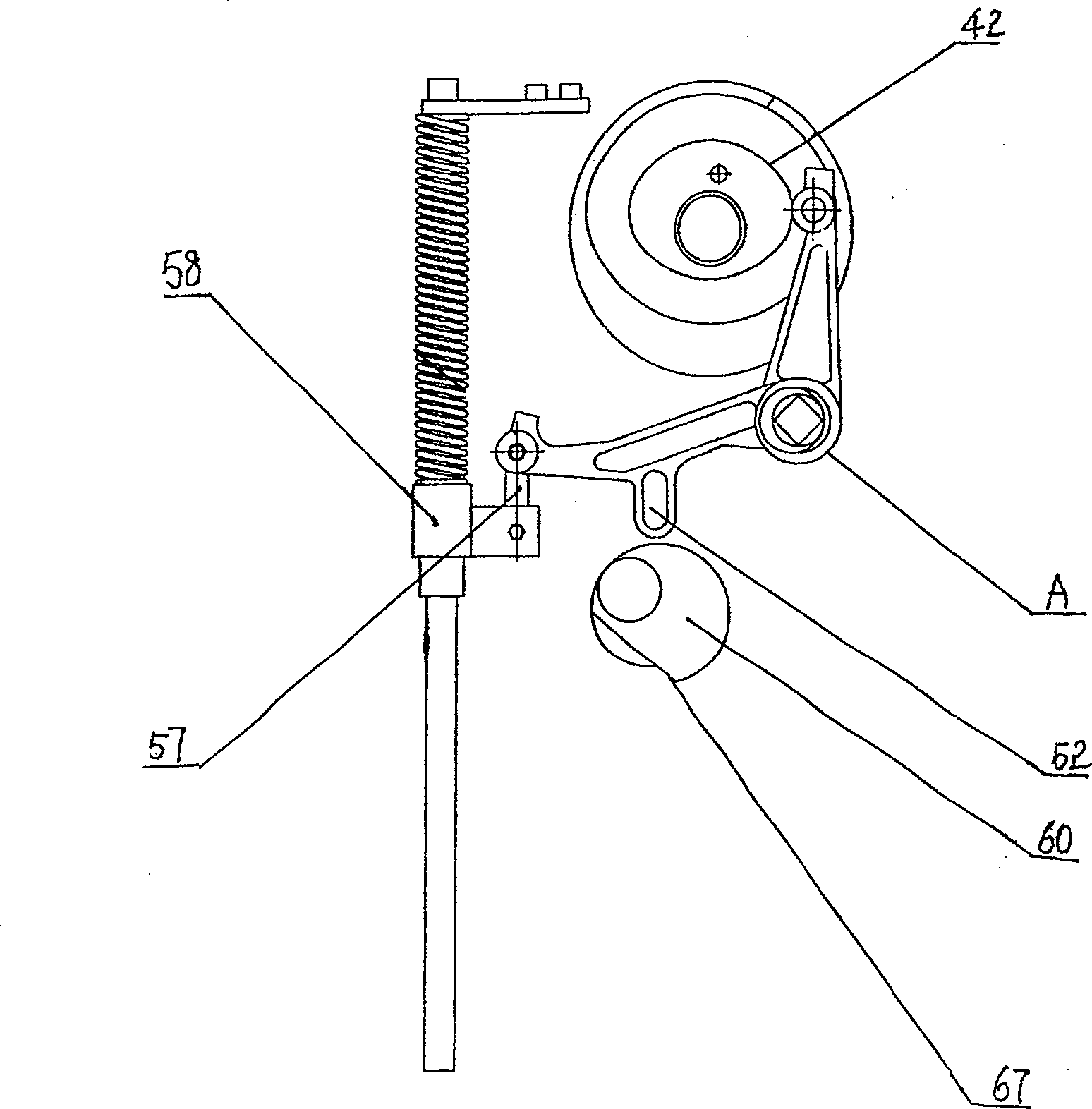

[0025] A driving mechanism is arranged on the main drive shaft, and the driving mechanism is composed of a presser foot driving cam 39 and a needle bar driving cam 40. The needle bar driving cam is a conjoined cam composed of a left cam disc 41 and a right cam disc 42. The presser foot driving cam is arranged on the needle bar driving camshaft 43; the eccentricity of the right cam disc of the needle bar driving cam 40 is 1.5, and the left cam disc is sl...

Embodiment 2

[0031] Example 2: The number of heads of the multi-head embroidery machine can be determined according to the user's requirements. If the output is small, it can be set as a single head; if the output is high, it can be set as multiple heads. The present embodiment adopts two heads, and its working process is similar to that of Embodiment 1, so it is not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com