Double-doped lithium niobate crystsal and method for making same

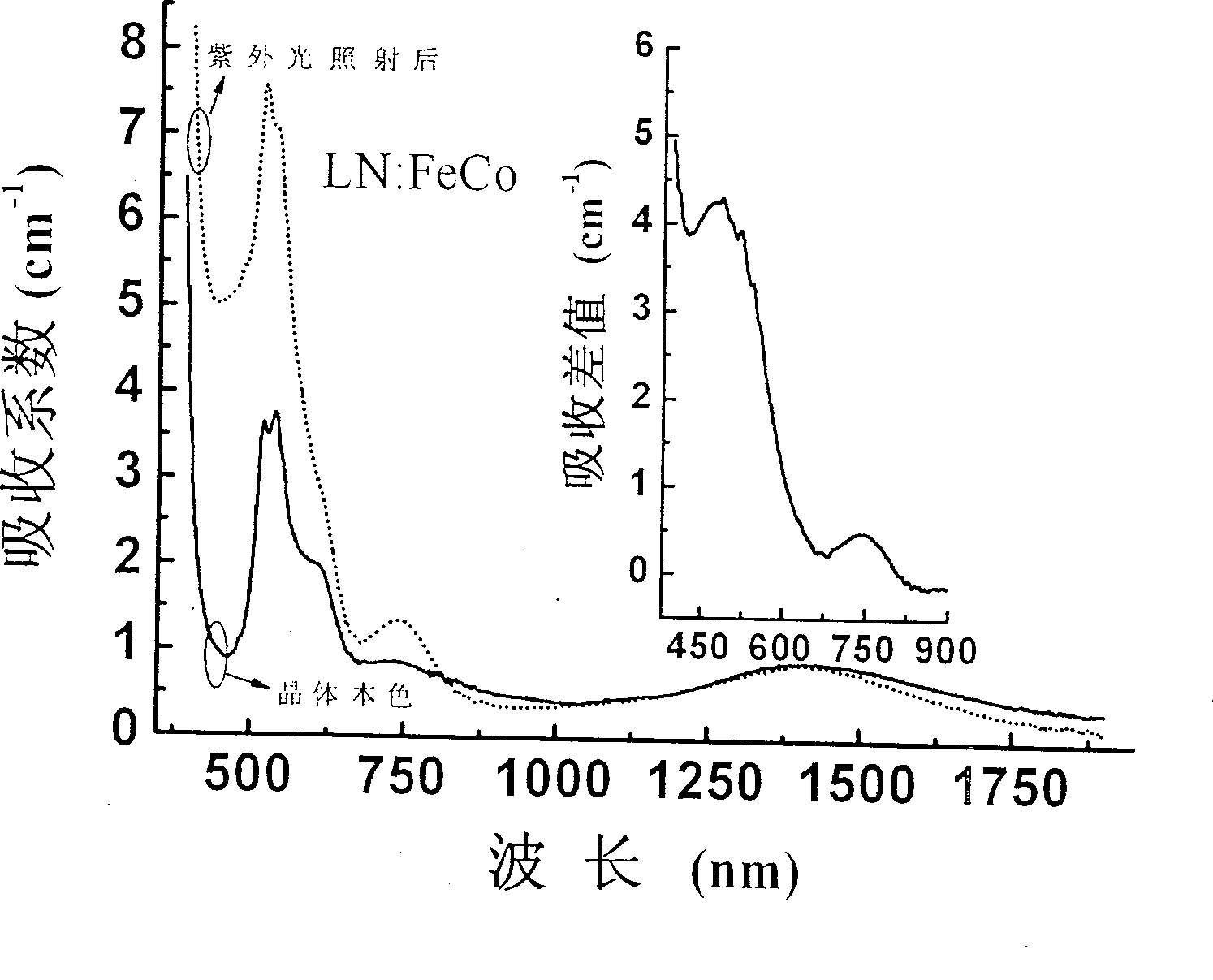

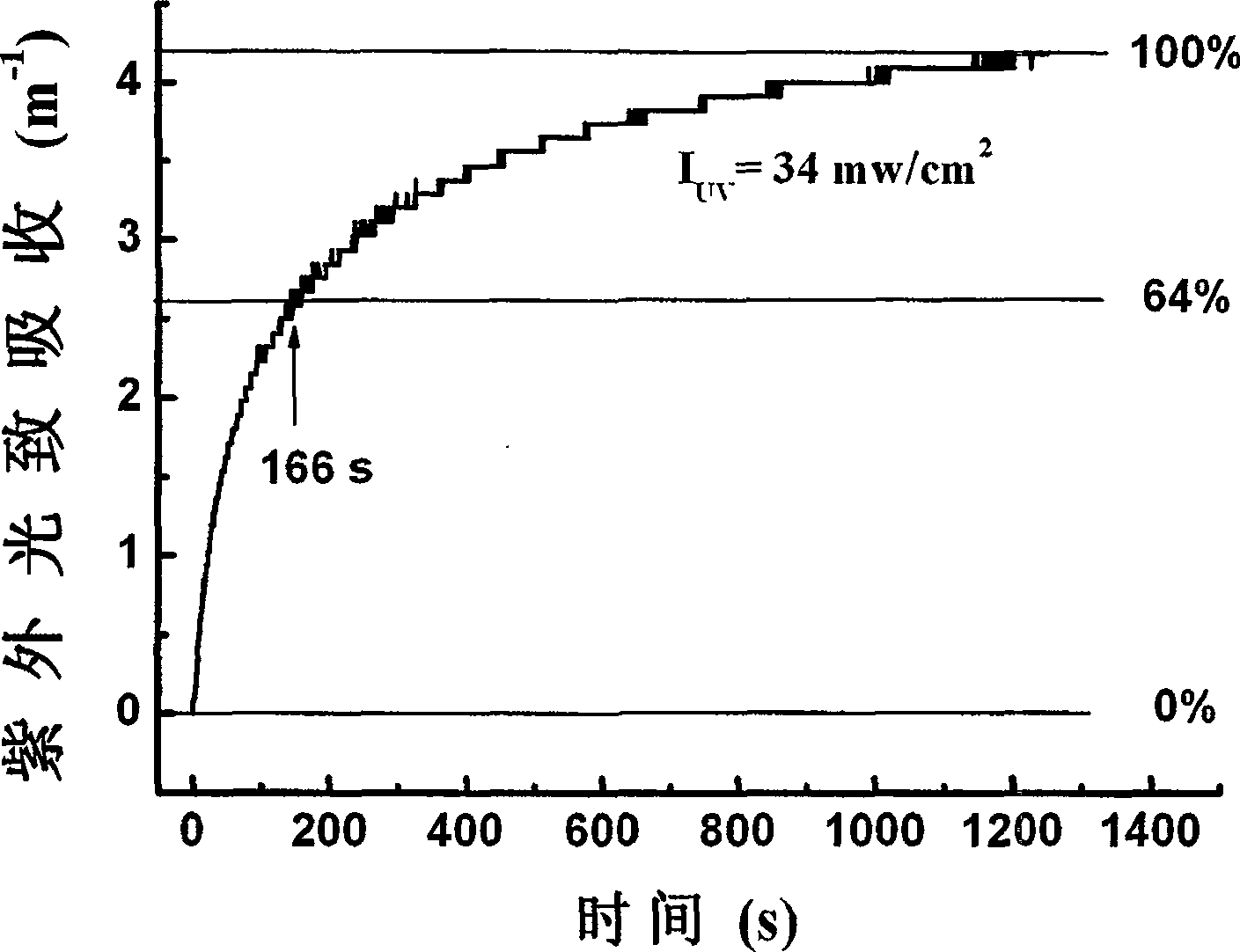

A technology of lithium niobate and crystal, which is applied in the field of double-doped lithium niobate crystal and its preparation, which can solve the problems of shortening response time, failure to improve dual-color storage performance, and long photochromic change response time, and achieve high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh Li with a purity of 99.99% 2 CO 3 , Nb 2 o 5 , Fe 2 o 3 , and Co 2 o 3 , according to the molar ratio of 9.3800mol: 10.0000mol: 0.0030mol: 0.0015mol, after drying at 150°C to remove moisture, fully mix in a ball mill for 24 hours, then keep the temperature at 800°C for 4 hours, and finally at 1000°C Calcined for 10 hours to obtain iron-cobalt double-doped lithium niobate polycrystalline purified powder;

[0027] (2) The iron-cobalt double-doped lithium niobate polycrystalline purified powder obtained in step (1) is compacted and placed in a platinum crucible, and the powder is heated by the medium-frequency induction crucible method until it melts, and the Czochralski pulling method is used along the c In the axial direction, seeding, necking, shouldering, equal diameter, and finishing processes are sequentially performed to obtain iron-cobalt double-doped lithium niobate crystals. During the crystal pulling process, the pulling speed is 2mm / h, the rot...

Embodiment 2

[0034] (1) Weigh Li with a purity of 99.99% 2 CO 3 , Nb 2 o 5 , Fe 2 o 3 , and Co 2 o 3 , according to the molar ratio of 9.3800mol: 10.0000mol: 0.0015mol: 0.0015mol, after drying at 170°C to remove moisture, fully mix in a ball mill for 36 hours, then keep the temperature at 850°C for 3 hours, and finally at 1050°C Calcined for 6 hours to obtain iron-cobalt double-doped lithium niobate polycrystalline purified powder;

[0035] (2) The iron-cobalt double-doped lithium niobate polycrystalline purified powder obtained in step (1) is compacted and placed in a platinum crucible, and the powder is heated by the medium-frequency induction crucible method until it melts, and the Czochralski pulling method is used along the c In the axial direction, seeding, necking, shouldering, equal diameter, and finishing processes are carried out in sequence to obtain iron-cobalt double-doped lithium niobate crystals. During the crystal pulling process, the pulling speed is 1mm / h, the rota...

Embodiment 3

[0039] (1) Weigh Li with a purity of 99.99% 2 CO 3 , Nb 2 o 5 , Fe 2 o 3 , and Co 2 o 3 , according to the molar ratio of 9.3800mol: 10.0000mol: 0.0050mol: 0.0015mol, dry at 200°C to remove moisture, mix thoroughly in a ball mill for 48 hours, then keep the temperature at 900°C for 2 hours, and finally calcined at 1100°C In 2 hours, the iron-cobalt double-doped lithium niobate polycrystalline purified powder was obtained;

[0040] (2) The iron-cobalt double-doped lithium niobate polycrystalline purified powder obtained in step (1) is compacted and placed in a platinum crucible, and the powder is heated by the medium-frequency induction crucible method until it melts, and the Czochralski pulling method is used along the c In the axial direction, seeding, necking, shouldering, equal diameter, and finishing processes are carried out in sequence to obtain iron-cobalt double-doped lithium niobate crystals. During the crystal pulling process, the pulling speed is 3mm / h, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com