Method and system for automatic generating shoe sole photopolymer coating track based on linear structure optical sensor

A line-structured light and automatic generation technology, which is applied to shoe soles, shoe-making machinery, footwear, etc., can solve the problems of unsatisfactory automation of shoe sole glue spraying process, difficult to guarantee accuracy, complicated operation, etc., to achieve high degree of automation and easy Easy maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

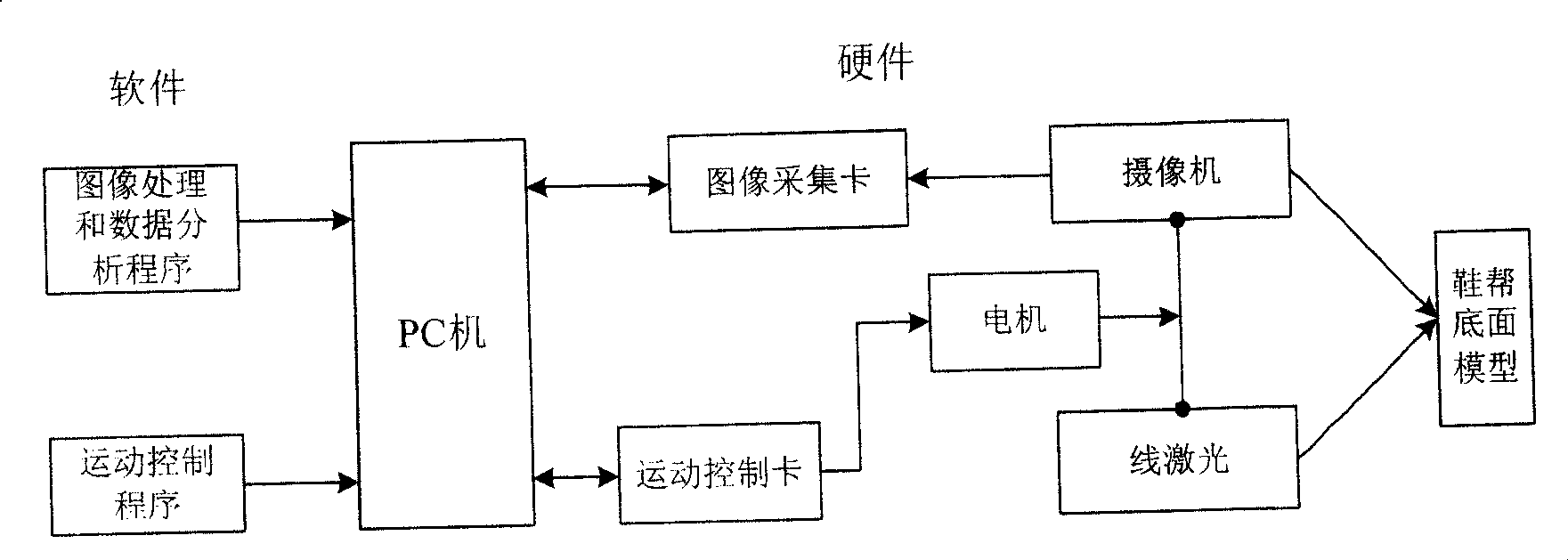

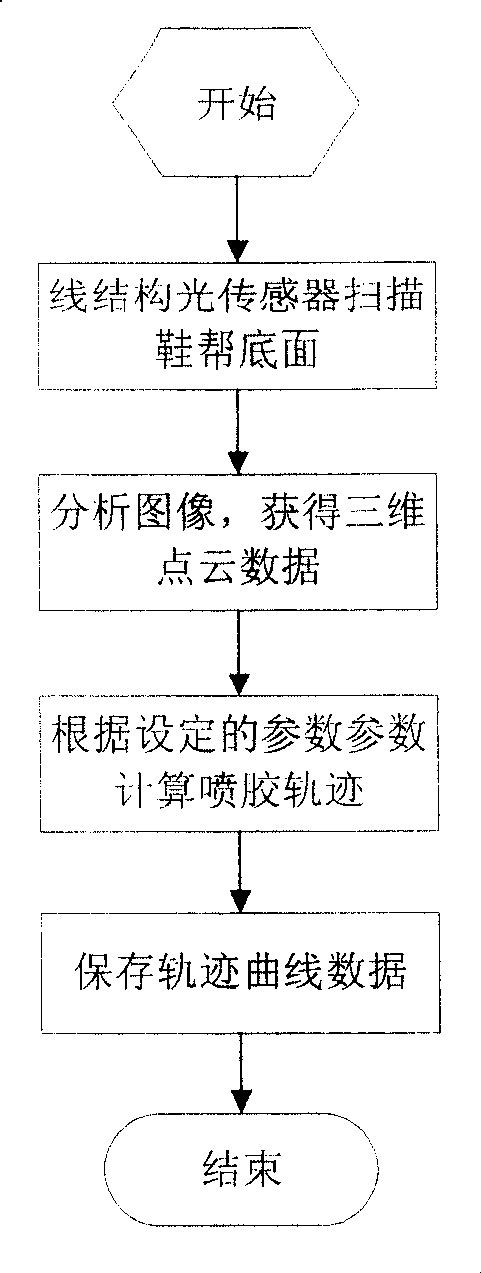

[0024] Such as figure 1 , figure 2 As shown, the present invention fixes the shoe last 1 on the experimental platform, the camera 4 and the line laser 2 are installed on the mobile platform 3, there is no relative movement between the camera 4 and the line laser 2, and the motor 5 drives the mobile platform 3 to move, driving The line laser 2 continuously scans the bottom surface of the shoe upper on the shoe last 1, the camera 4 collects images and connects them to the PC through the image acquisition card, and the PC controls the motor 5 through the motion control card.

[0025] The image acquisition card is PXC-200L series or similar products.

[0026] The motion control card mentioned is GT-400-SG series and similar products.

[0027] Such as figure 1 As shown, the present invention includes two parts: a hardware part and a software part. The hardware part mainly includes image acquisition card, camera, motion control card, motor, line laser and computer; the software...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com