Sealing property testing equipment

A testing device and technology for sealing performance, which are used in fluid tightness testing, measuring devices, and liquid tightness measurement using liquid/vacuum degree. Safety and other issues, to achieve the effect of strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

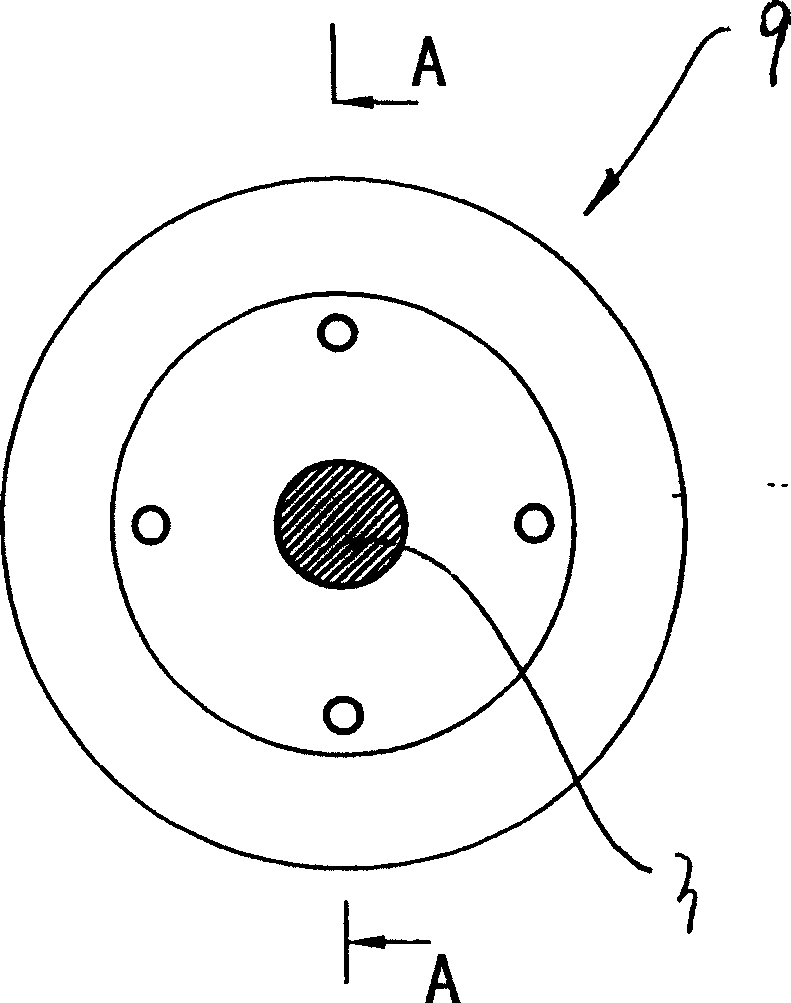

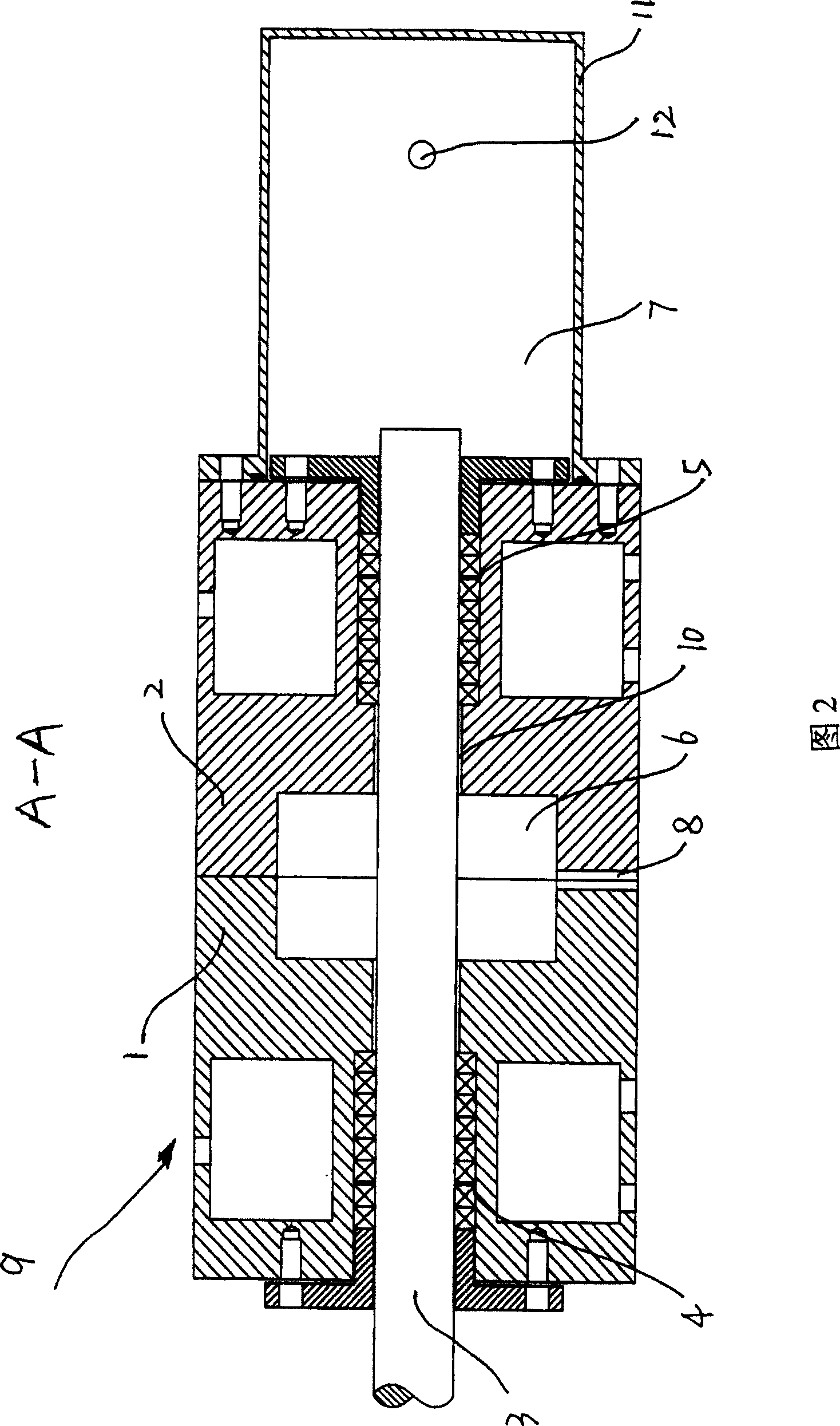

[0016] See attached figure 1 Referring to accompanying drawing 2, a sealing performance testing device includes a main body 9 and a valve stem 3. The main body 9 has a valve stem chamber 10 penetrating through the main body 9. The valve stem 3 is slidably arranged in the valve stem chamber 10. Part of the valve stem The cavity 10 is radially enlarged to form a packing cavity for placing the packing, and the main body 9 has a high-pressure cavity 6 communicating with the stem cavity 10 . The main body 9 is composed of a first main body 1 and a second main body 2 , the first main body 1 is in contact with the second main body 2 , and the stem chamber 10 runs through the first main body 1 and the second main body 2 . The high pressure chamber 6 is symmetrically located on the abutting surface of the first body 1 and the second body 2 .

[0017] The second main body 2 has a first through hole 8 , the first through hole 8 communicates with the high pressure chamber 6 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com