Film magnetic head and making method thereof

A technology for thin-film magnetic heads and manufacturing methods, applied to magnetic heads and magnetic recording heads using thin films, which can solve problems such as insufficient durability and water corrosion resistance, and achieve fewer manufacturing processes, excellent durability, and strong adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

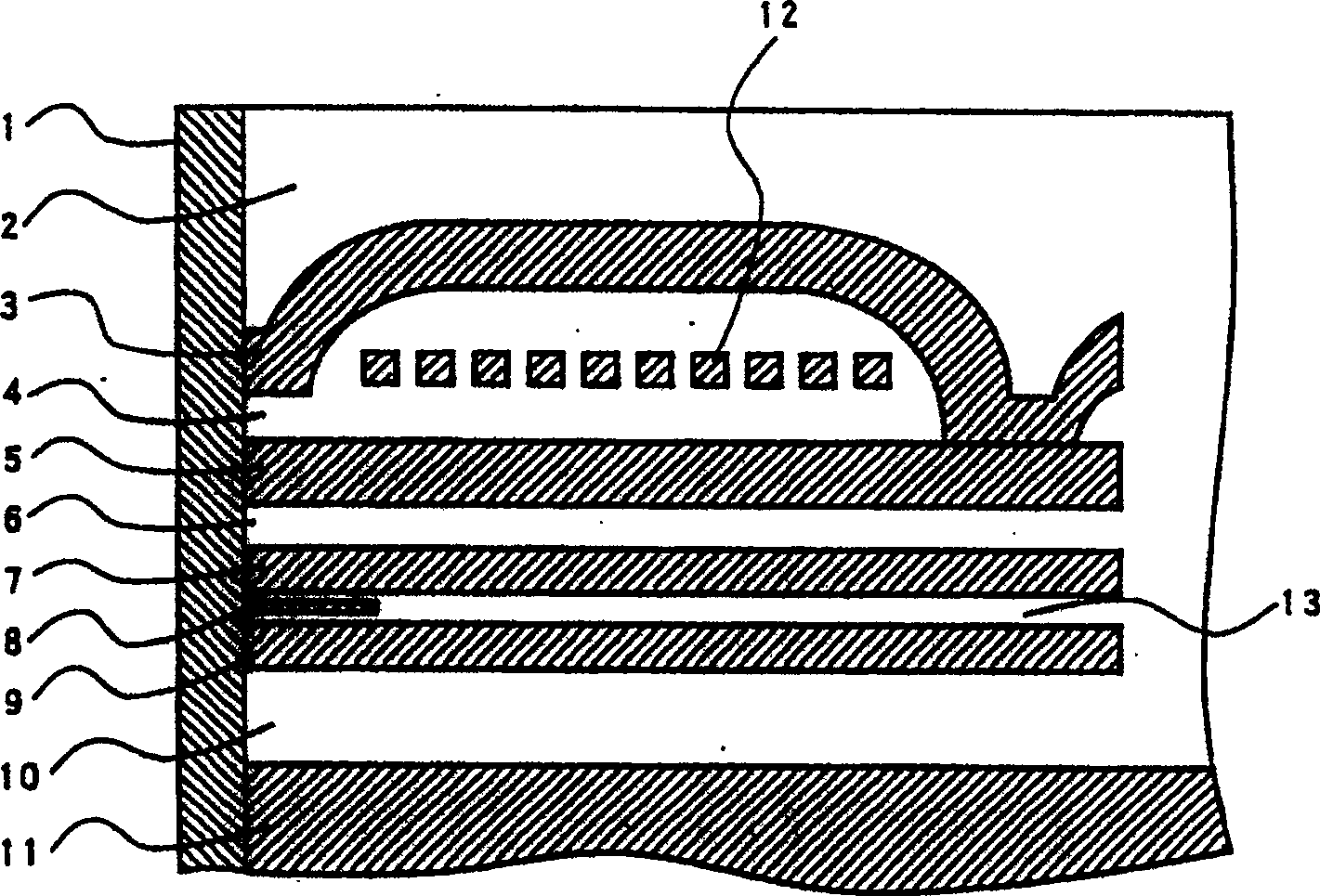

Image

Examples

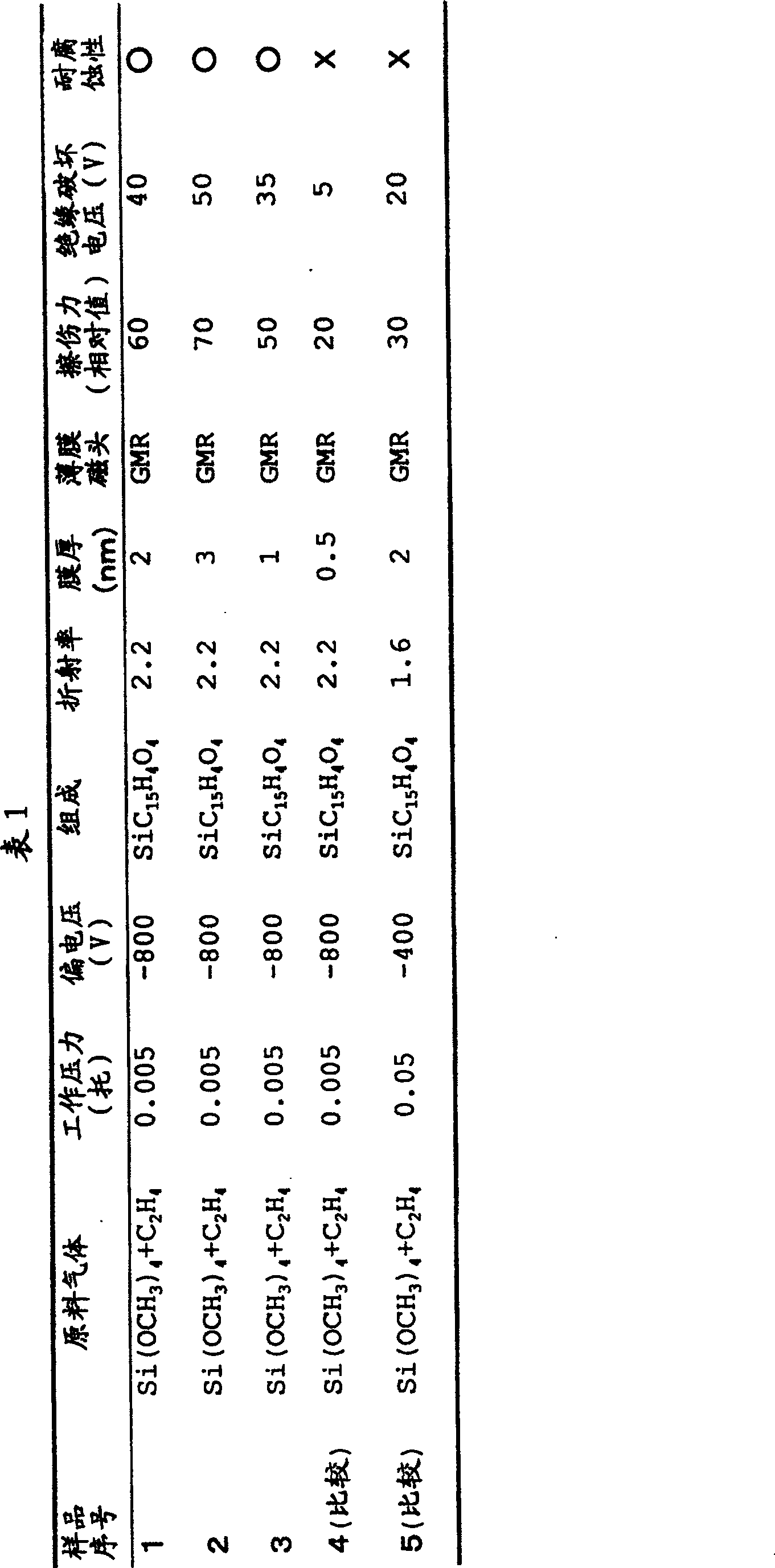

Embodiment 1

[0084] Si(OCH 3 ) 4 and C 2 h 4 Raw material gases as compounds containing Si, C, H, and O were introduced at flow rates of 5 SCCM and 10 SCCM, respectively. Apply RF500W as an alternating current for plasma generation, and form a protective film with a thickness of 2nm on the moving surface or sliding surface of the GMR thin-film magnetic head with a self-bias of -800V under an operating pressure of 0.005 Torr. Take it as sample 1.

[0085] For sample 1, samples 2 to 4 were obtained except that the thickness of the protective film was changed as shown in Table 1.

[0086] In addition, for sample 1, except that the working pressure is 0.05 Torr and the self-bias voltage is -400V, other things are unchanged, and sample 5 is obtained.

[0087] The properties of the samples thus obtained were evaluated as follows, and the evaluation results are shown in Table 1. In addition, the composition measured by the chemical analysis of the formed film was also recorded. The refract...

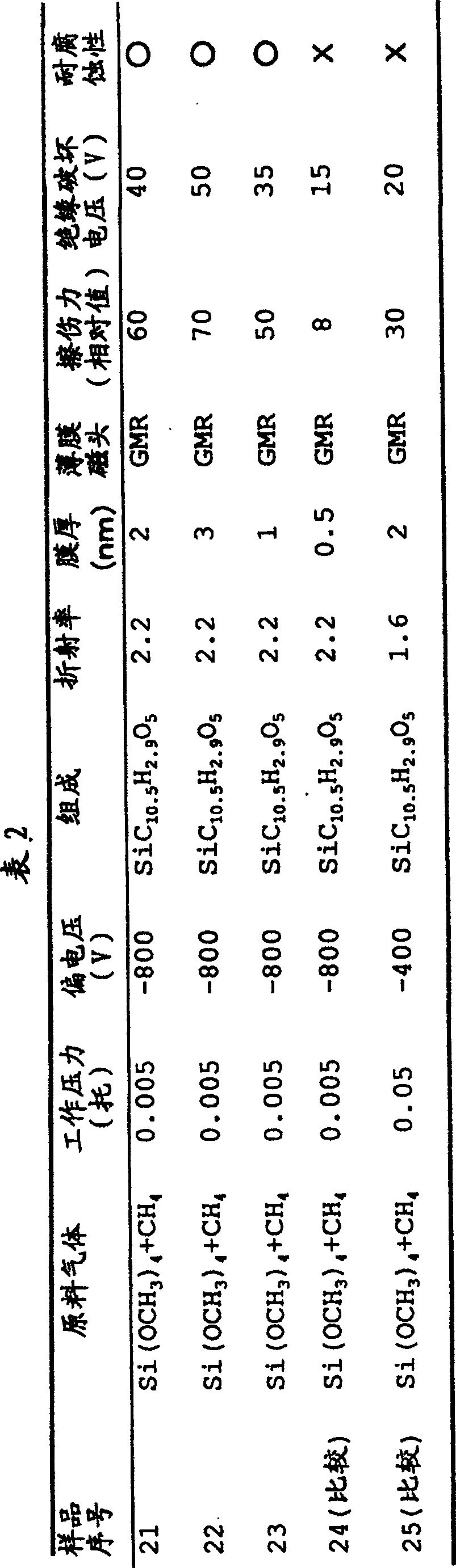

Embodiment 2

[0099] Si(OCH 3 ) 4 and CH 4 Raw material gases as compounds containing Si, C, H, and O were introduced at flow rates of 5 SCCM and 6 SCCM, respectively. Apply RF500W as an alternating current for generating plasma, and use self-bias -800V or -400V to form a film at a working pressure of 0.005 Torr or 0.05 Torr on the moving surface or sliding surface of the GMR thin film magnetic head. In the same manner as in Example 1, the samples shown in Table 2 were obtained and their characteristics were evaluated, and the evaluation results are shown in Table 2.

[0100]

Embodiment 3

[0102] SiH 4 , CO 2 and CH 4 Raw material gases as compounds containing Si, C, H, and O were introduced at flow rates of 20 SCCM, 10 SCCM, and 50 SCCM, respectively. Apply RF500W as an alternating current for generating plasma, and use self-bias -800V or -400V to form a film at a working pressure of 0.005 Torr or 0.05 Torr on the moving surface or sliding surface of the GMR thin film magnetic head. In the same manner as in Example 1, the samples shown in Table 3 were obtained and their characteristics were evaluated. Table 3 shows the evaluation results.

[0103]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com