High elastic rubber alloy shaft coupling device

A high-elasticity rubber and coupling technology, used in elastic couplings, couplings, mechanical equipment, etc., can solve the problems of reducing the torsional vibration strength of the elastomer, reducing the maximum torque, and rubber elastic fatigue damage. Effects of unbalanced moment, enhanced torsional vibration strength, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

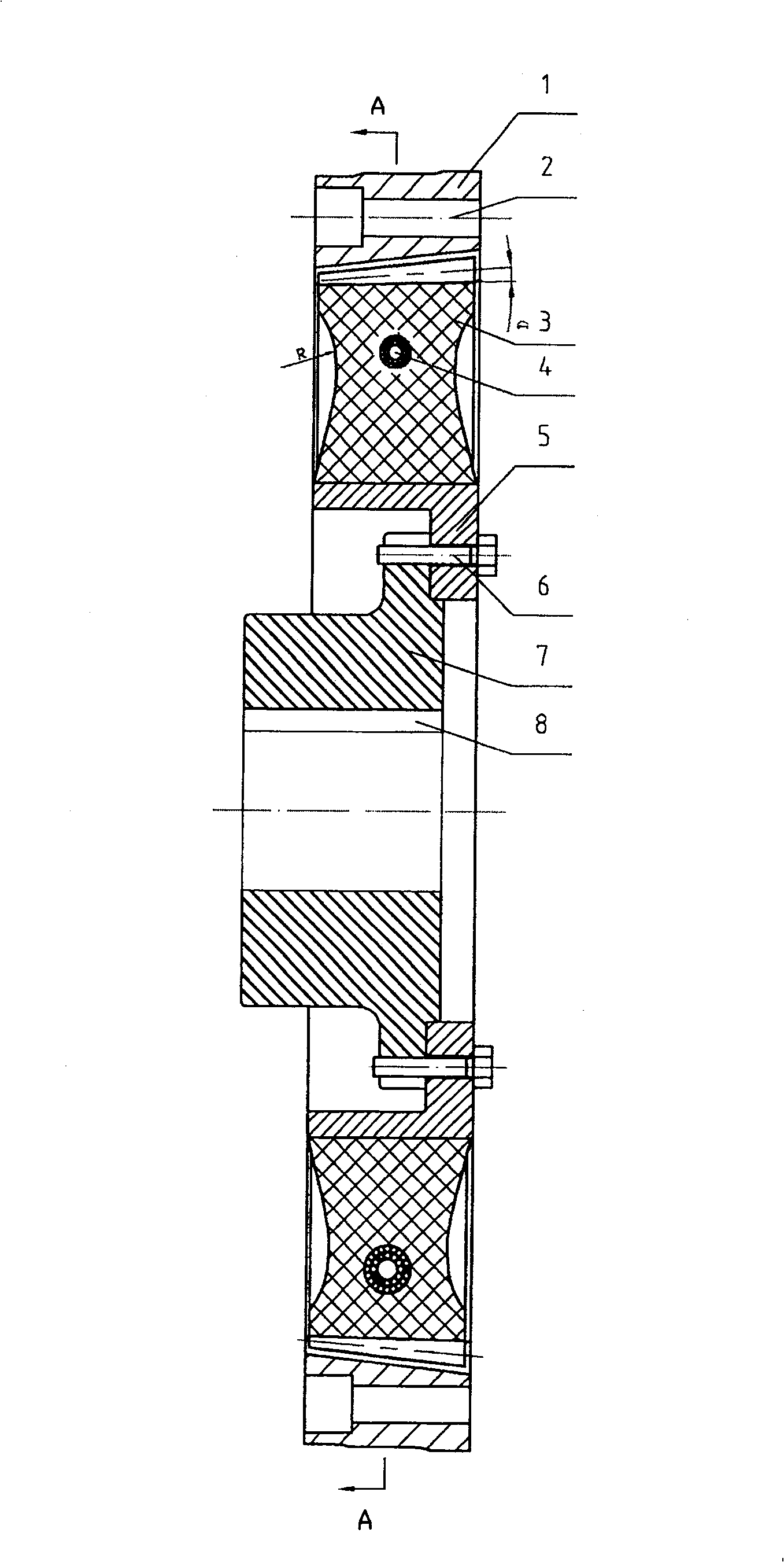

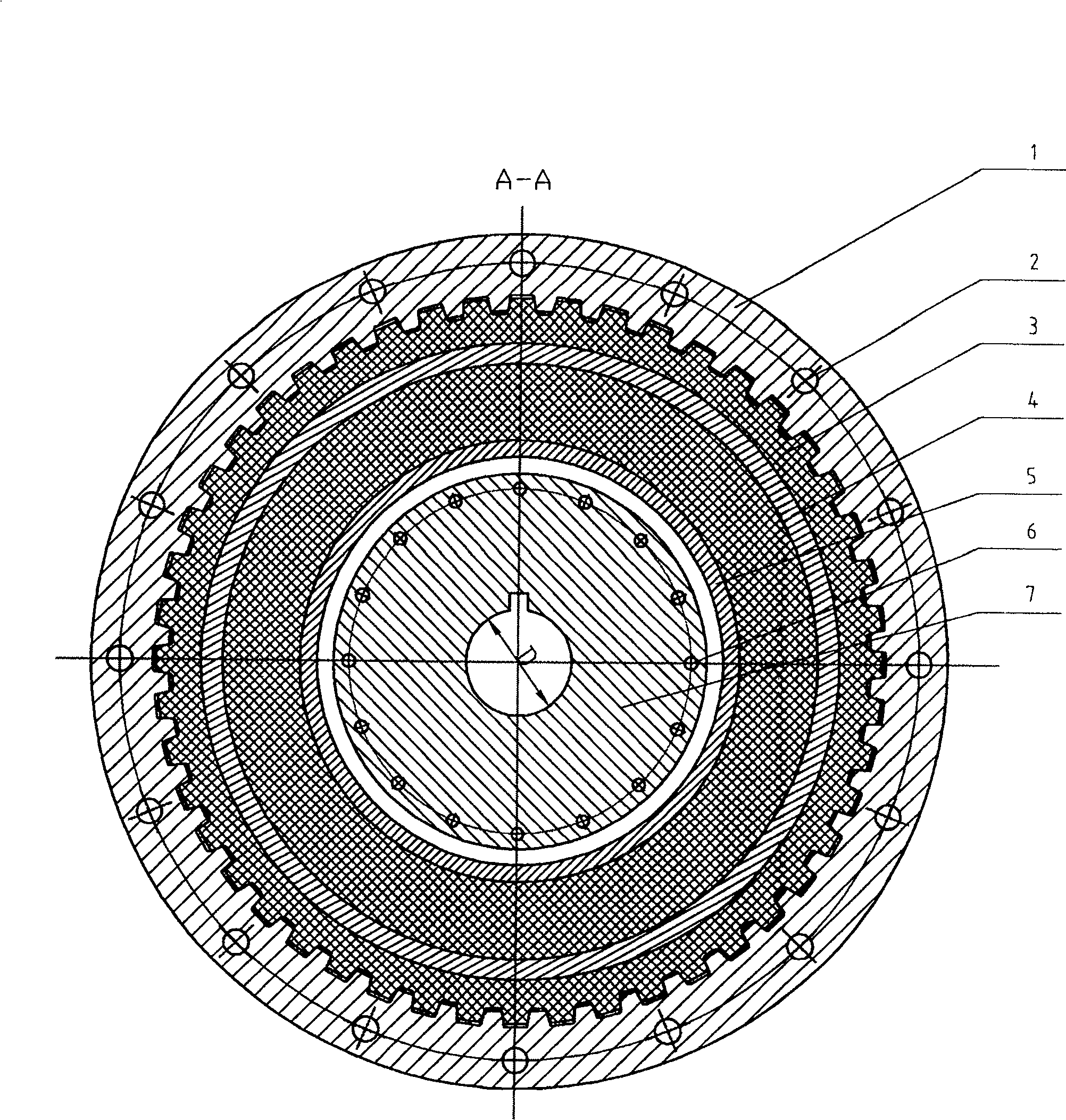

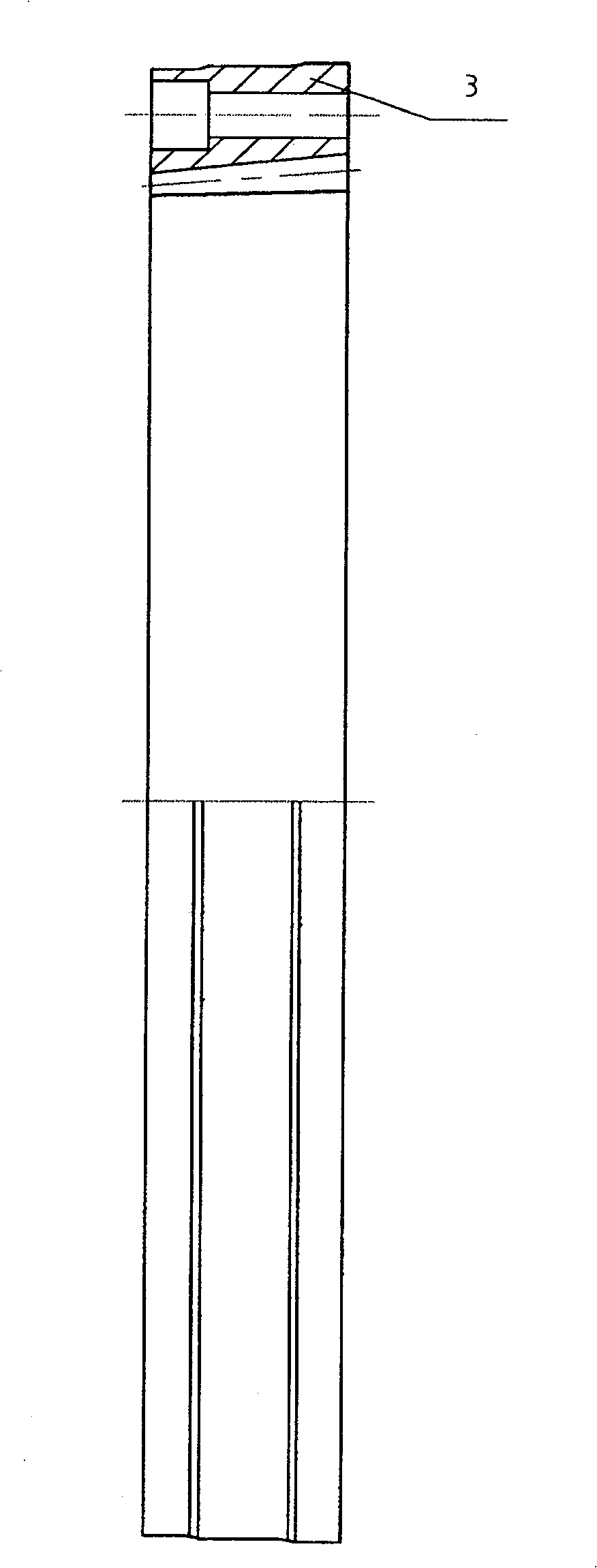

[0018] The vulcanization process of the elastic body 3 of the high-elastic rubber alloy coupling, the material of the elastic body 3 is a polymer rubber composite material modified and reinforced by nano-scale ZnOw with a weight percentage of 3%, placed in an open machine X(S)K-230 Glue in. β left-handed and right-handed threads with a certain helix angle are respectively processed on the outer surface of the circumference of the output coupling disc 5. After coating the special adhesive, the output coupling disc 5 and the steel wire ring 4 are placed in the vulcanization mold, and then squeezed out by the extrusion die. The raw materials obtained from rubber mixing are extruded into the vulcanization mold, and finally the assembled vulcanization mold is placed in the digital flat vulcanization equipment, the vulcanization temperature is set at 180°C, the vulcanization time is 70 minutes, and the vulcanization pressure is 46kkg.

[0019] Such as Figure 5 As shown, the high e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com