System for detecting polarization maintaining optical fiber beat length

A polarization-maintaining optical fiber and detection system technology, which is applied in optical instrument testing, machine/structural component testing, measuring devices, etc., can solve the problems of low cost of measuring instruments and the influence of the minimum value of the beat length, etc., and achieves a simple and easy measurement method. performance, improve measurement accuracy, and reduce vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

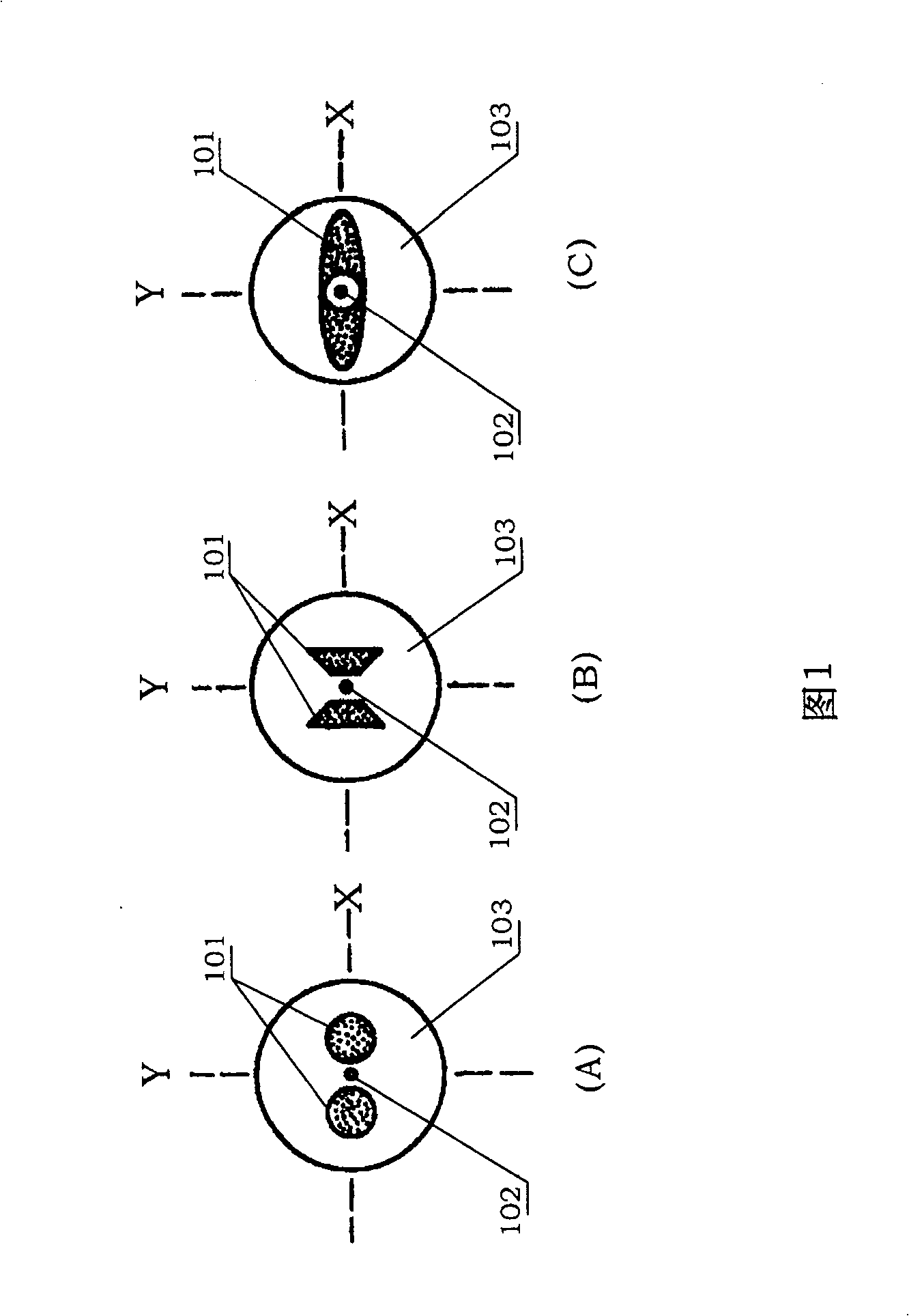

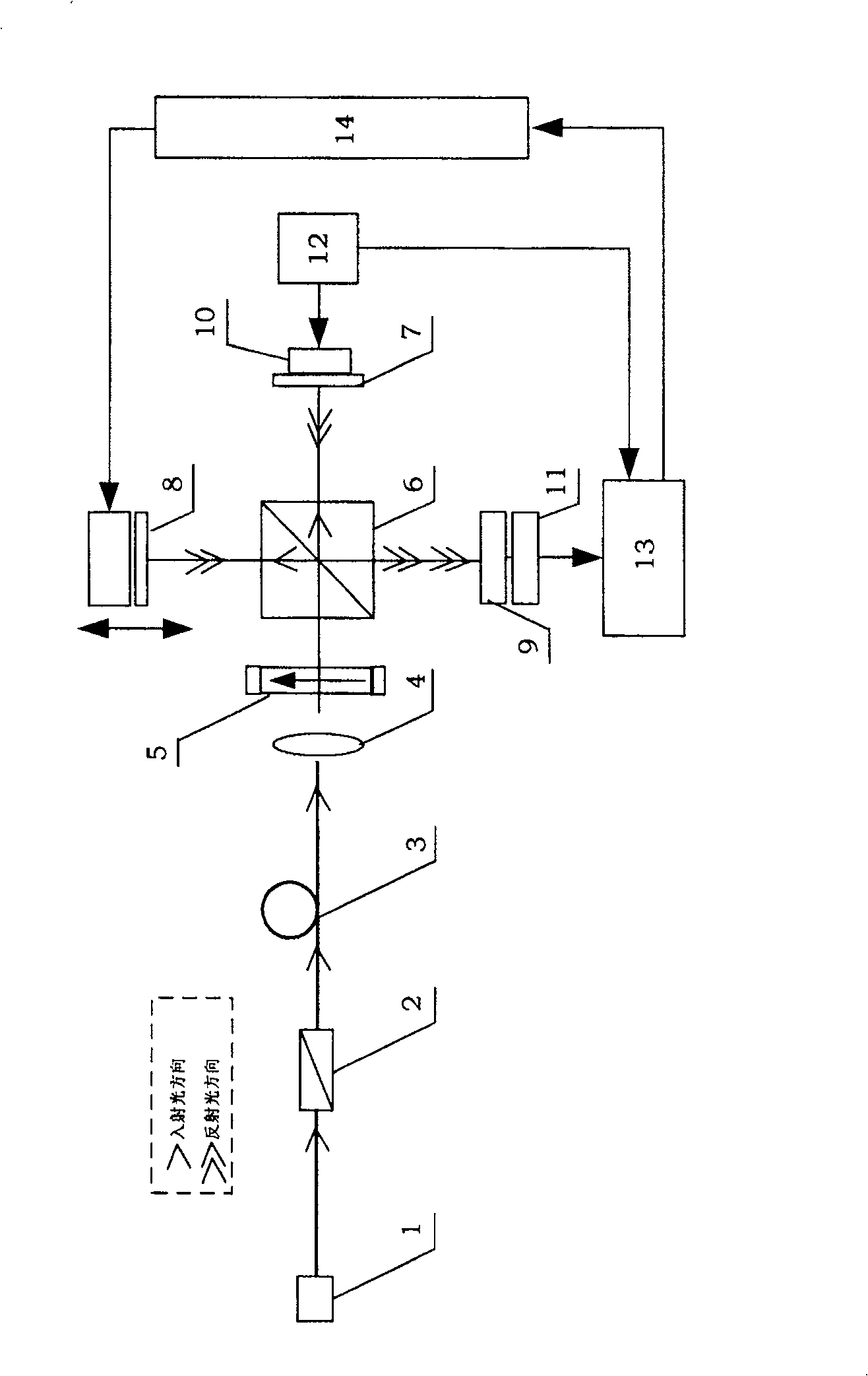

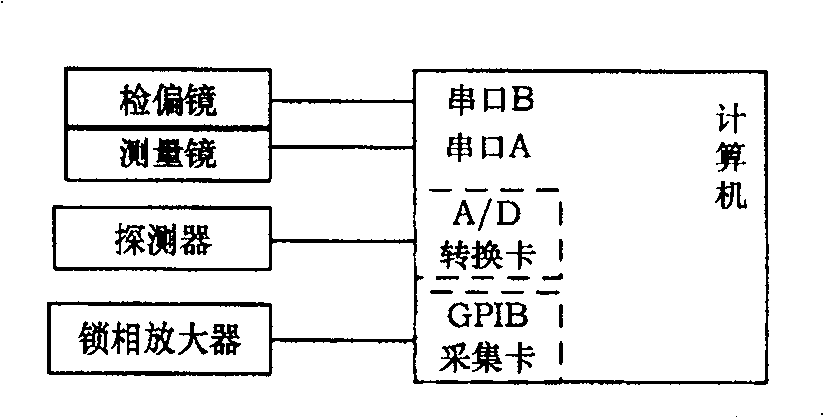

[0027]Please refer to shown in Fig. 2, the present invention is a kind of detection system to the beat length of polarization-maintaining optical fiber, by wide-spectrum light source 1, optical fiber polarizer 2, photodetector 9, Michelson interferometer, signal generator 12, lock It consists of a phase amplifier 13, a computer and a beat length detection device stored in the computer. Described Michelson interferometer comprises coupling lens 4, analyzer mirror 5, spectroscope 6, reference mirror 7 and measurement mirror 8, and the optical path relation of these five mirrors is: (A) the light that couples through coupling lens 4 enters detector On the polarizer 5, the light after the analyzer 5 is incident on the beam splitter 6; (B) the light incident on the beam splitter 6 is transmitted to the reference mirror 7, and the light reflected by the reference m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com