Slider for slide fastener with automatic stopper

An automatic braking and zipper technology, applied in the field of zipper sliders, can solve problems such as complex slider structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

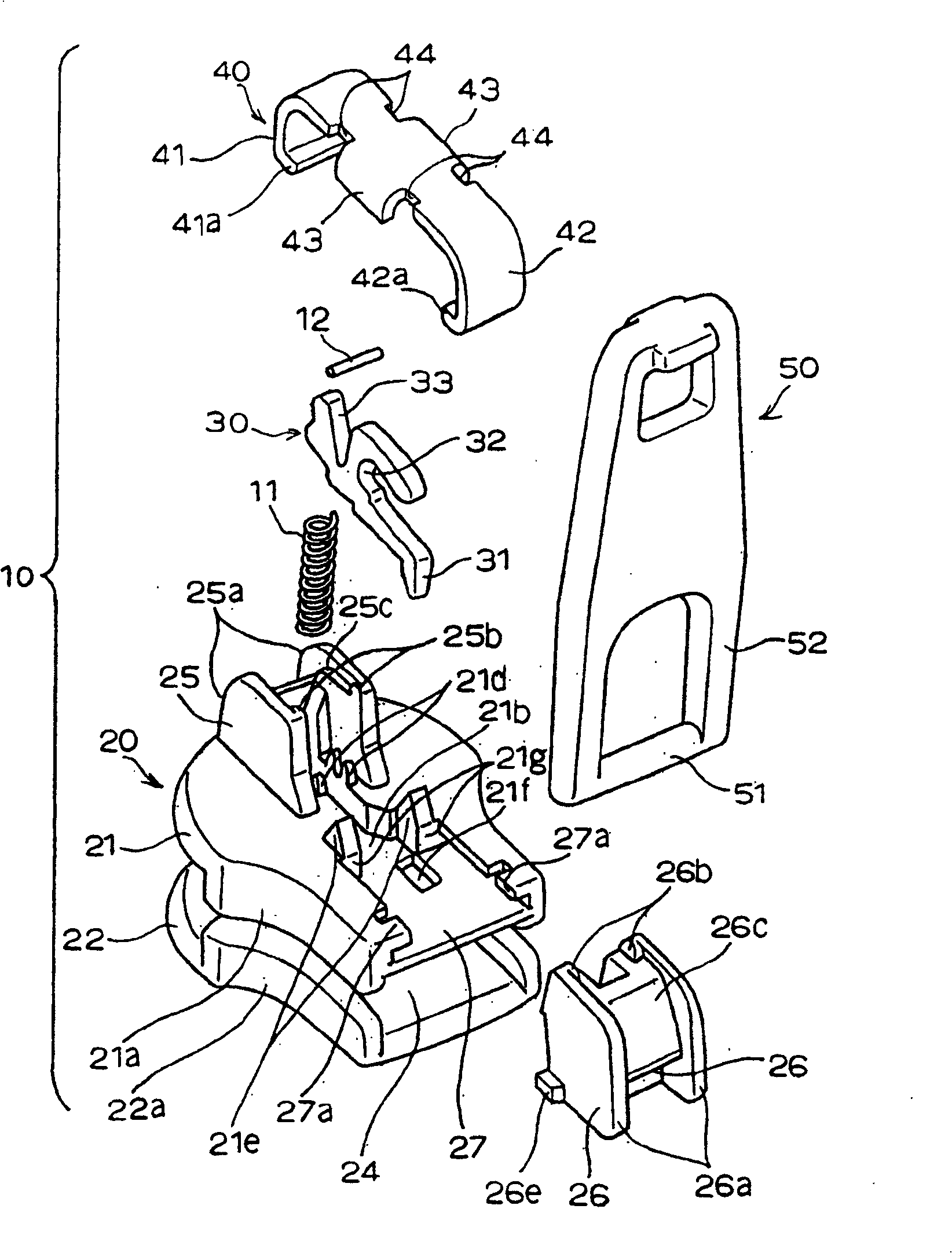

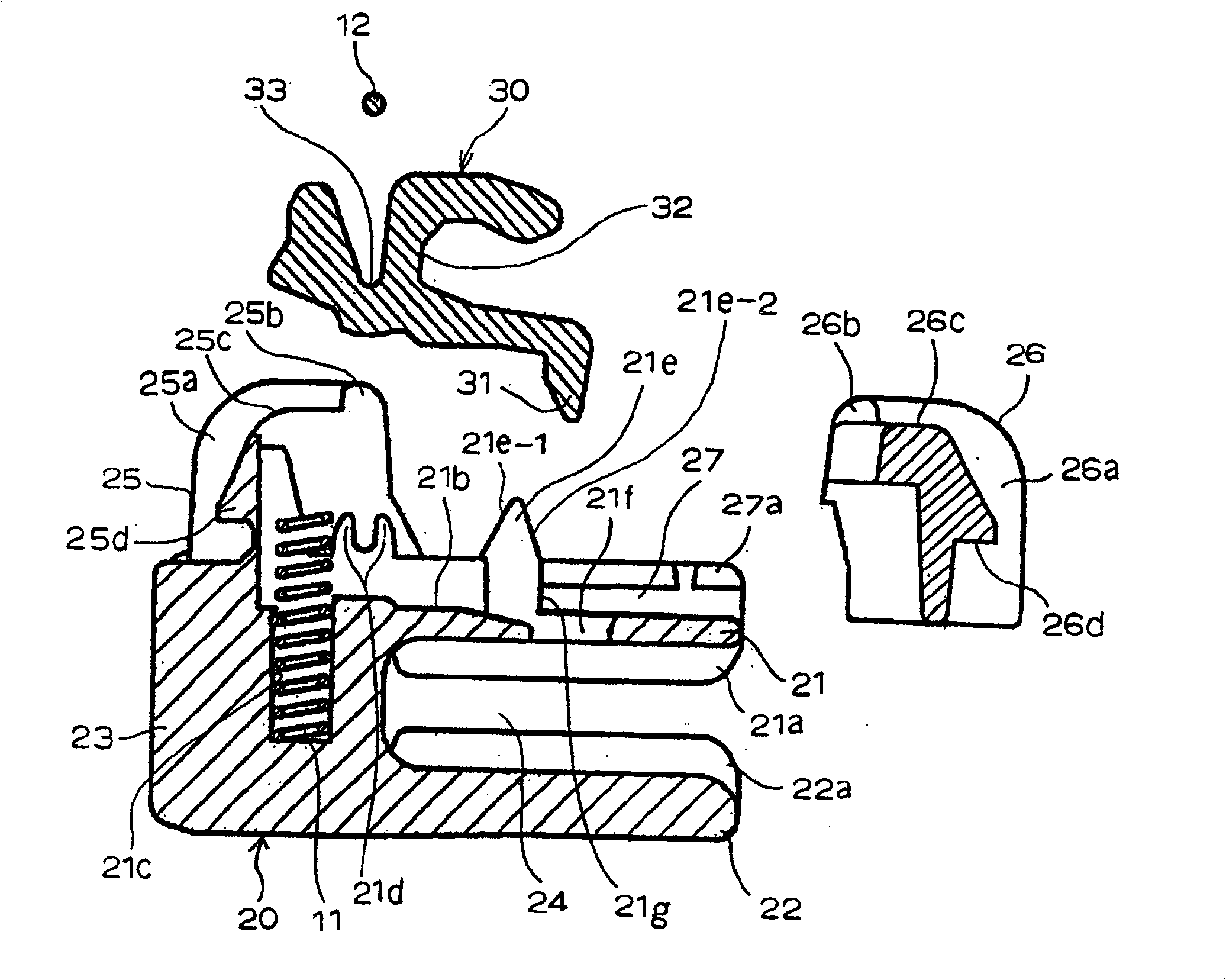

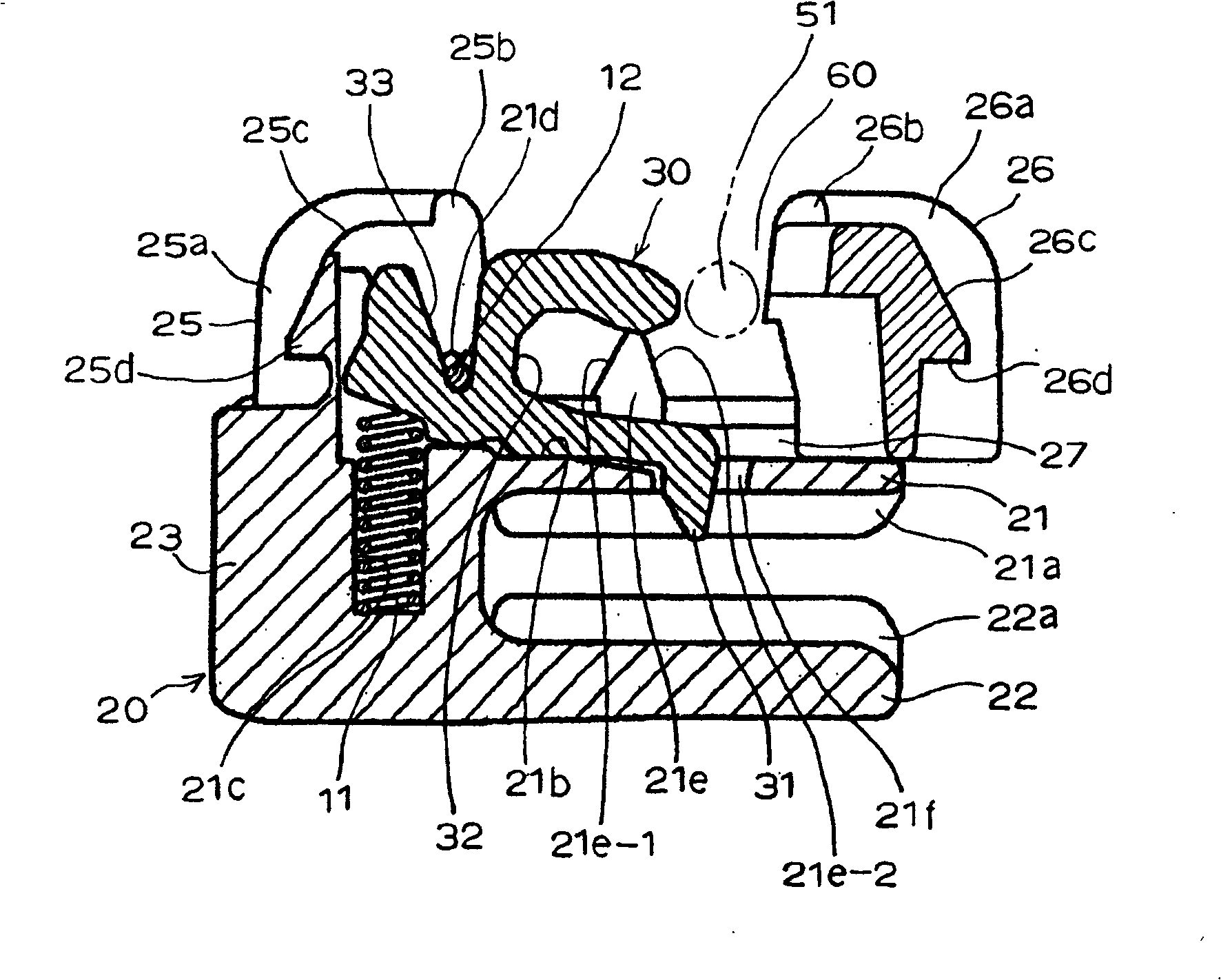

[0074] Figures 1 to 9 A representative first embodiment of the present invention is shown. figure 1 is a perspective view showing a disassembled state of parts constituting a slider for a zipper with an automatic stopper. Figures 2 to 8 is a longitudinal sectional view of the main part showing the assembly steps of the same slider, while Figure 9 is a perspective view of the same slider. In this embodiment, the shoulder side of the slider ( figure 1 The left side of the slider) is called the front, and the rear opening side of the slider ( figure 1 middle right) is called the posterior.

[0075] (first embodiment)

[0076] refer to figure 1 , the slider 10 for a slide fastener with an automatic brake includes a slider body 20, a front mounting column 25, a rear mounting column 26, a pawl bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com