Foundation for an offshore wind energy plant

A technology for wind power generation equipment and seabed, which is applied to wind turbine components, wind energy power generation, wind turbines, etc., can solve the problems of poor material utilization and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

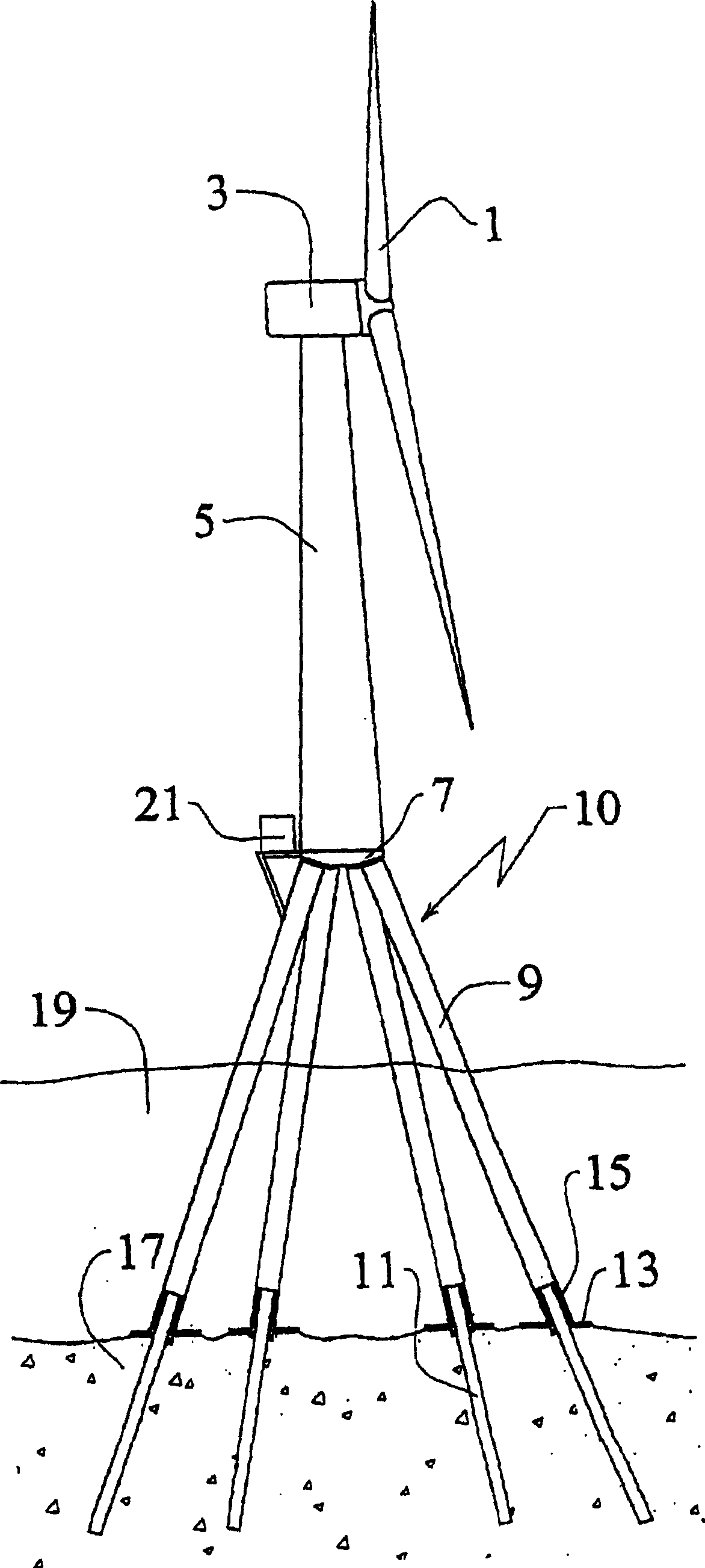

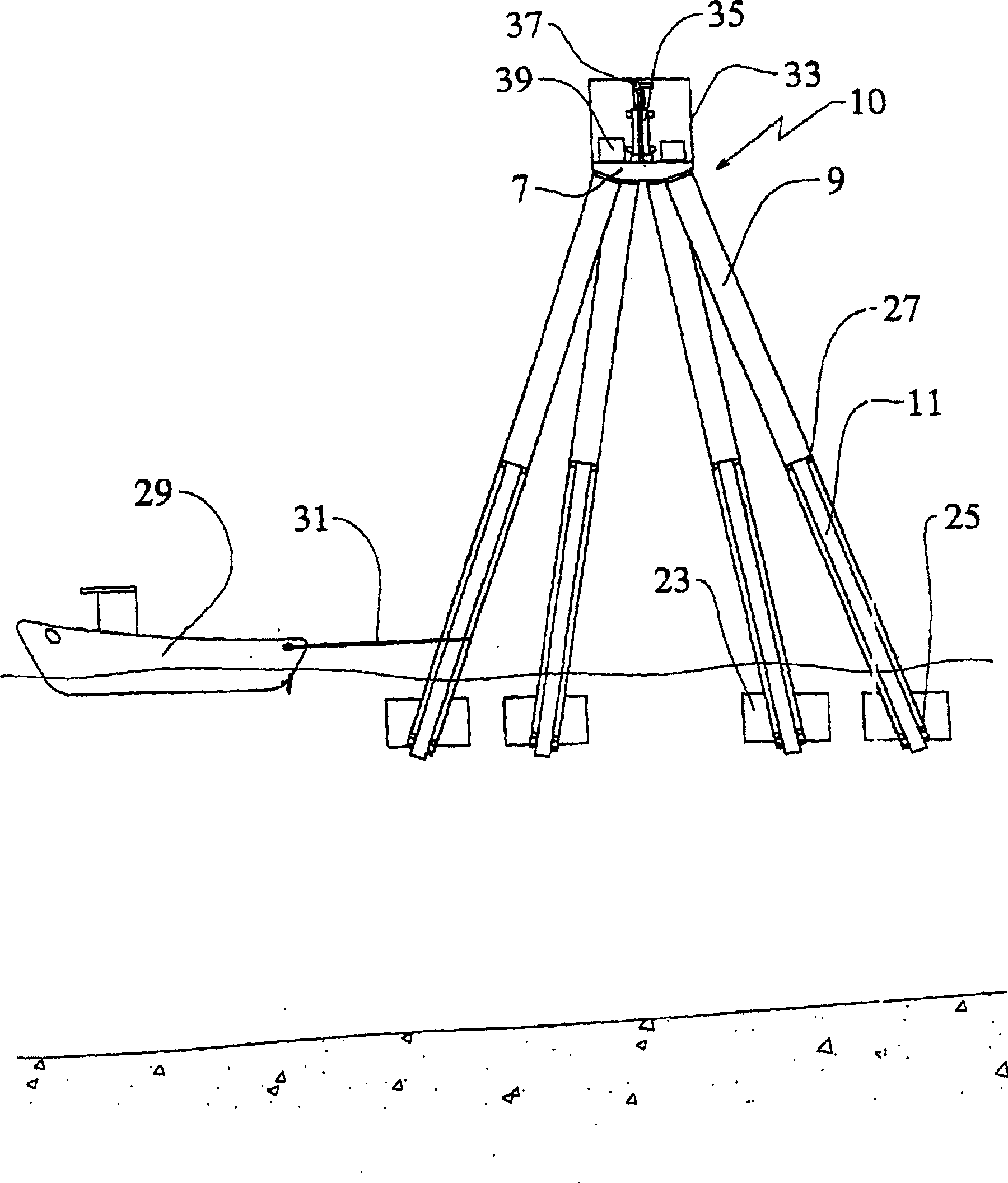

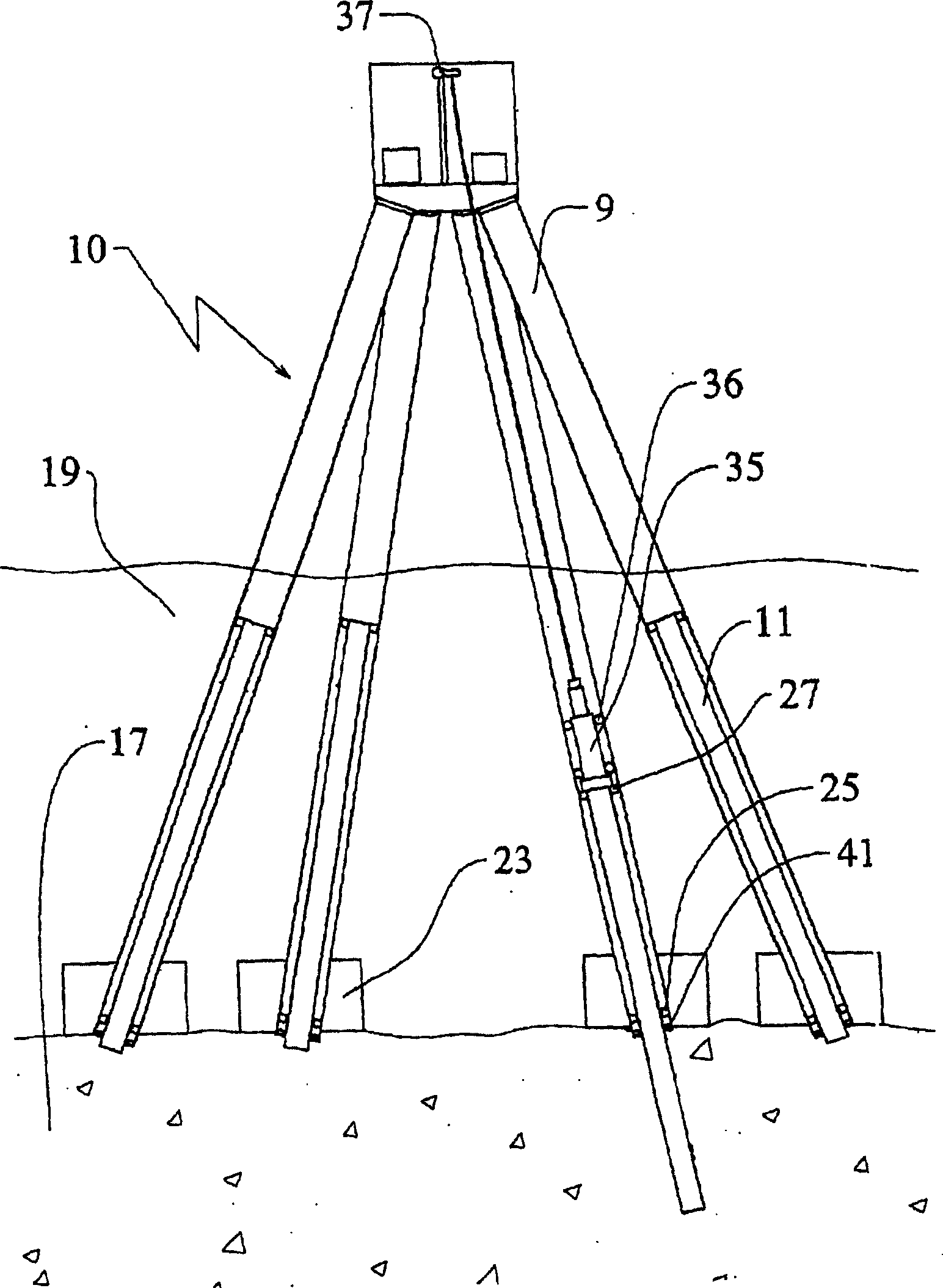

[0040] figure 1 The overall installed offshore wind power plant shown includes a rotor 1 in the form of converting wind energy into usable energy. The equipment pod 3 houses the necessary parts and components and is connected to the tower 5 by a swivel connection. Tower 5 has a flange at its lower end. The tower 5 is connected to the load distribution 7 by suitable connections. A plurality of base legs 9 are attached to the load distribution member 7 at a small angle of 10° to 30° relative to the vertical. A plurality of foundation legs 9 are connected by driven piles 11 driven into the seabed 17 . Base plates 13 are installed at the lower ends of the base legs to reduce the sinking of the structure into the seabed 17 . A potting or connection with a suitable material such as concrete is provided between the foundation leg 9 and the driven pile 11 . The overall height of the foundation 10 with its foundation legs 9 is dimensioned such that the largest expected waves will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com