Washing machine sterilizing reagent kit and its sterilizing method

A technology for a kit and a washing machine, which is applied to other washing machines, control devices of washing machines, washing devices, etc., can solve the problem that the volume of the sterilizing water generating mechanism 22 is not improved, and achieve a simple structure, a large space, and a long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

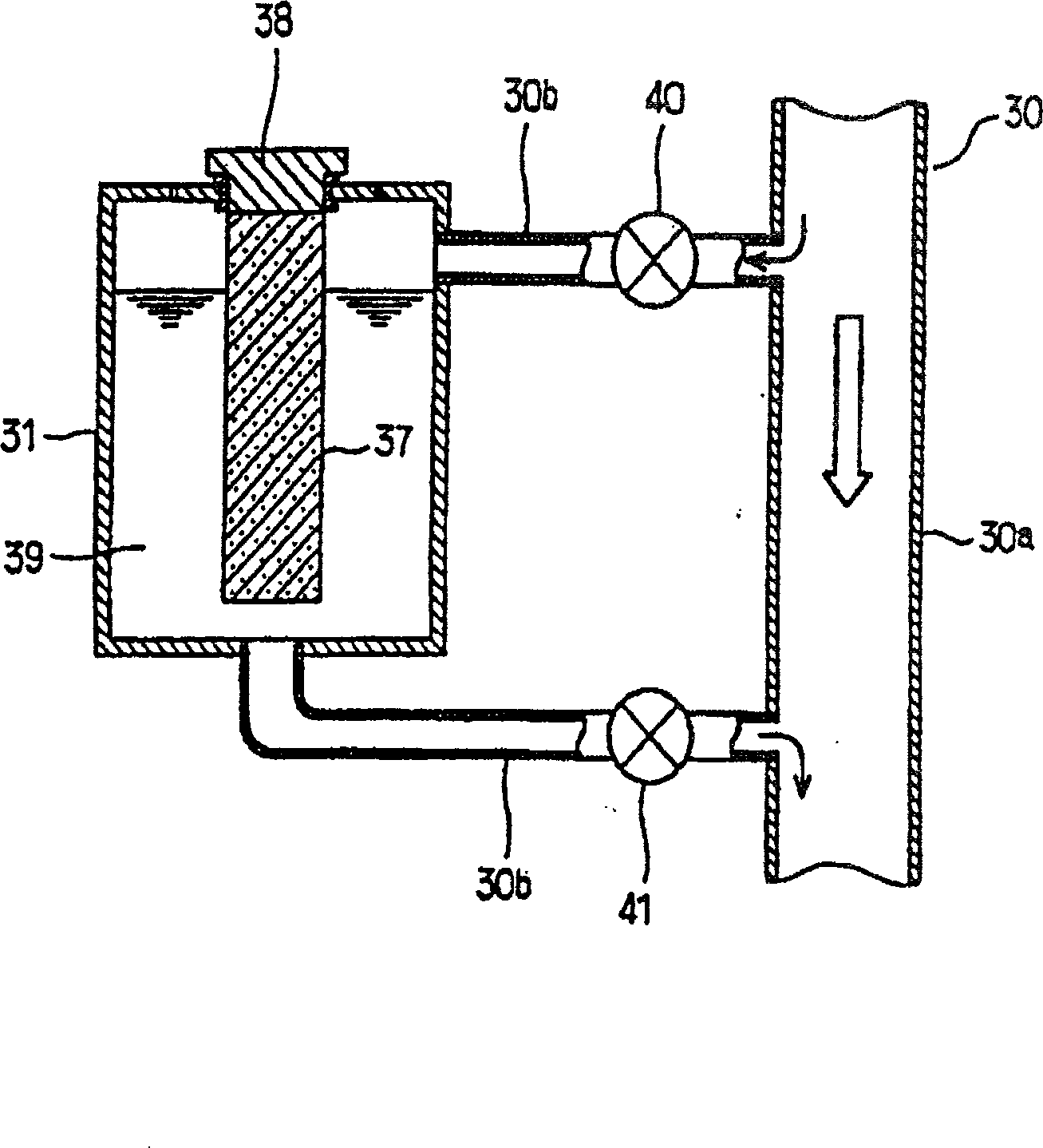

[0035] As shown in Figure 5, it is a cross-sectional view of an embodiment of the disinfection kit of the present invention. In the water inlet hole 2, it includes: a box body 1, a water injection hole 2 arranged at the bottom of the box body 1, and a drainage hole 3. The water injection hole 2 Connected with the water inlet valve 21, the box body 1 includes: an outer box 11 and an inner box 12, the outer box 11 and the inner box 12 are fixedly arranged as one, and the siphon device 4 is arranged on the inner box 12 At the bottom, a baffle 5 is provided between the outer box 11 and the inner box 12 on the side where the drainage hole 3 is provided, and an overflow hole 51 is opened on the upper part of the baffle 5 to maintain the water level in the outer box 11 at the equilibrium water level H The bottom of the baffle plate 5 is provided with a drain hole 52 that facilitates part of the water flowing into the washing tub, and the top of the inner box 12 is provided with a cove...

Embodiment 2

[0041] Figure 5 is a cross-sectional view of another embodiment of the disinfection kit of the present invention, its structure is substantially the same as that shown in Figure 4, the difference is that no independent water inlet valve is provided at the water inlet 2 The inner box 12 can also be fixedly sleeved in the outer box 11 from top to bottom, and a drainage control valve 31 is provided on the drainage path of the drainage hole 3 .

[0042] The disinfection method in this embodiment is the same as the main steps disclosed in the embodiment, the difference is that the water intake is controlled by the softener control valve, and the water discharge is controlled by the drain control valve 31 .

[0043] In step a, the water source first enters the outer box 11 through the water injection hole 2, a part of the water flows into the washing tub through the drain hole 52 and the drain hole 3, and the other part of the water passes through the siphon device 4 arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com