Composite lens system

A compound lens system and lens technology, applied in the field of compound lens systems, can solve the problems of unavoidable spherical aberration, increased lens weight, small lens size, etc., and achieve good optical imaging performance and avoid spherical aberration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

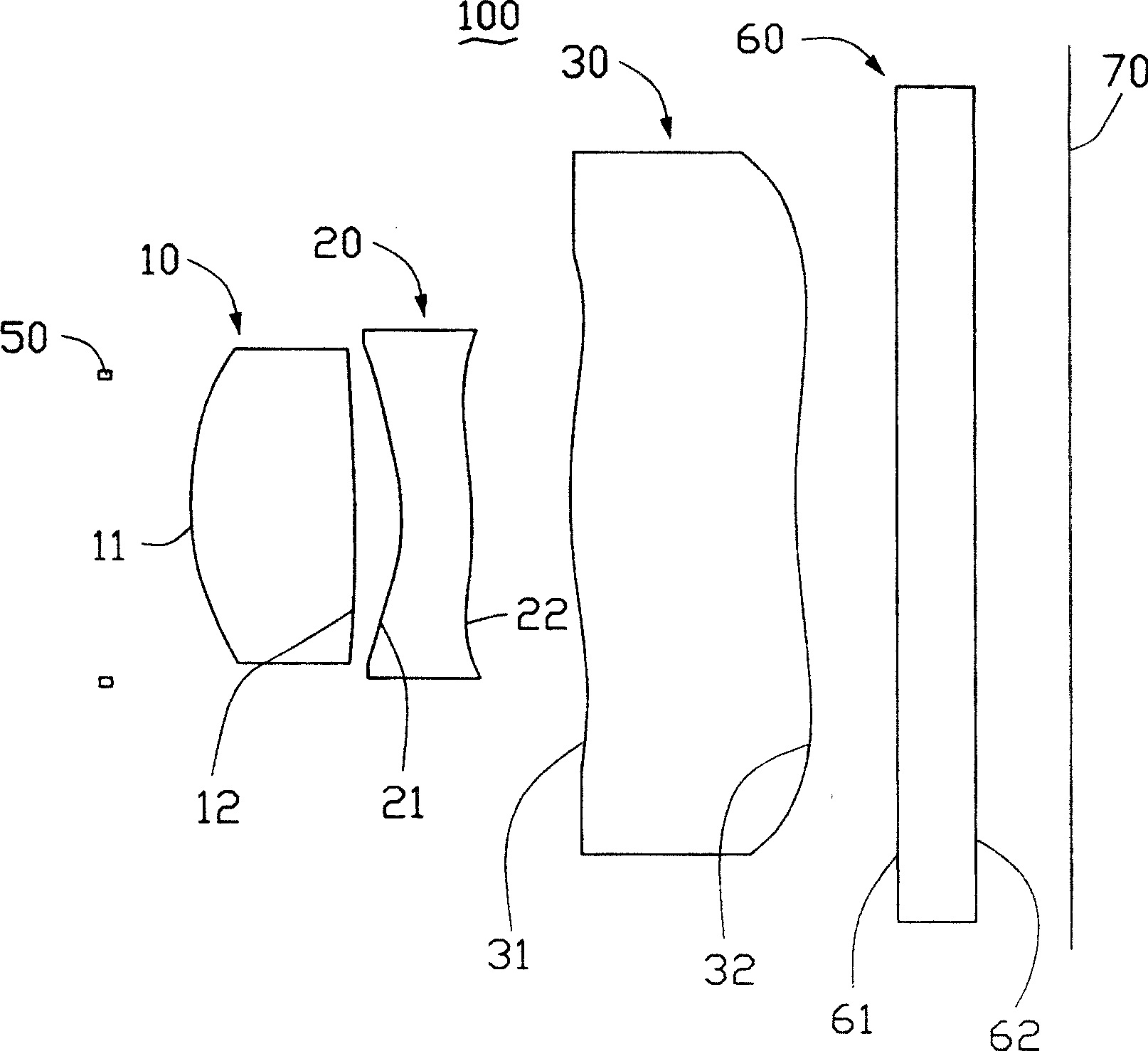

[0034] see figure 1 , which is a compound lens system 100 according to the first embodiment of the present invention, including: a first lens 10, a second lens 20, and a third lens 30 arranged in order from the object side to the image side. In addition, a diaphragm 50 is disposed on the object side of the first lens 10 , and a flat plate element 60 and an image sensor 70 are sequentially disposed on the image side of the third lens 30 .

[0035] The first lens 10 is a lens with a positive focal length, and the range of refractive index and dispersion is 1.551 1 2 2 3 3 <60 is made of optical plastic material, the fifth surface 31 is convex, and the sixth surface 32 is concave. In this embodiment, the preferred plastic material model for making the third lens is E48R.

[0036] The diaphragm 50 is used to limit the beam aperture passing through the first, second and third lenses 10 , 20 , 30 and to limit the field of view. The image sensor 70 can be a CMOS (Complementary Meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com