Fluidised bed gas and solid contacting device

A technology of gas-solid contact and fluidized bed, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve difficult problems such as stripping efficiency and low efficiency, and achieve improved gas-solid contact efficiency, easy installation, and mass transfer The effect of thermal enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

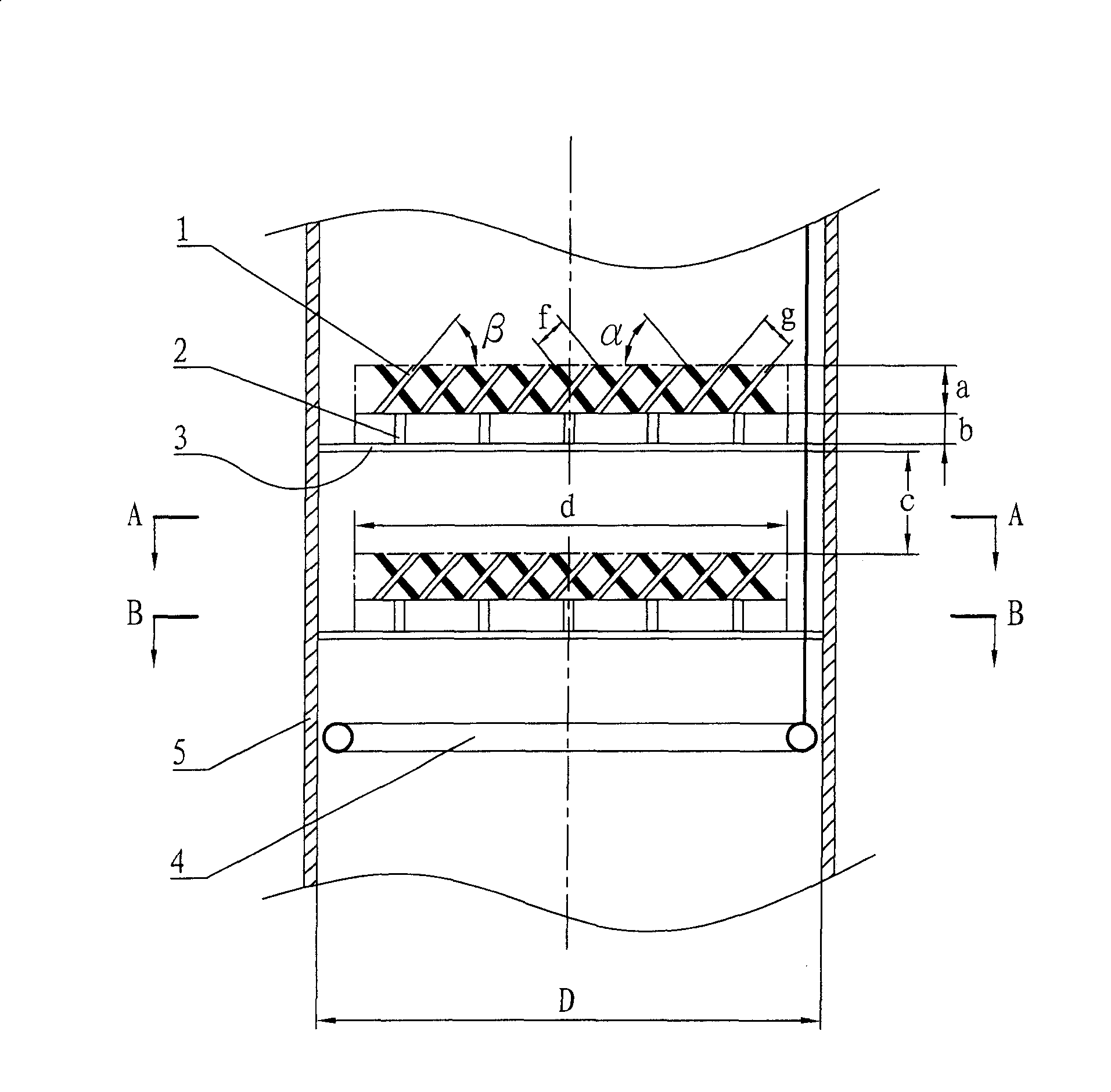

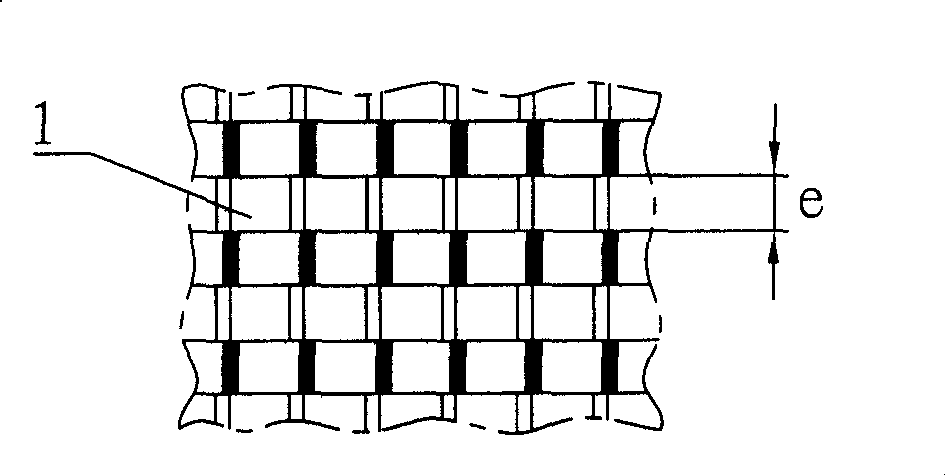

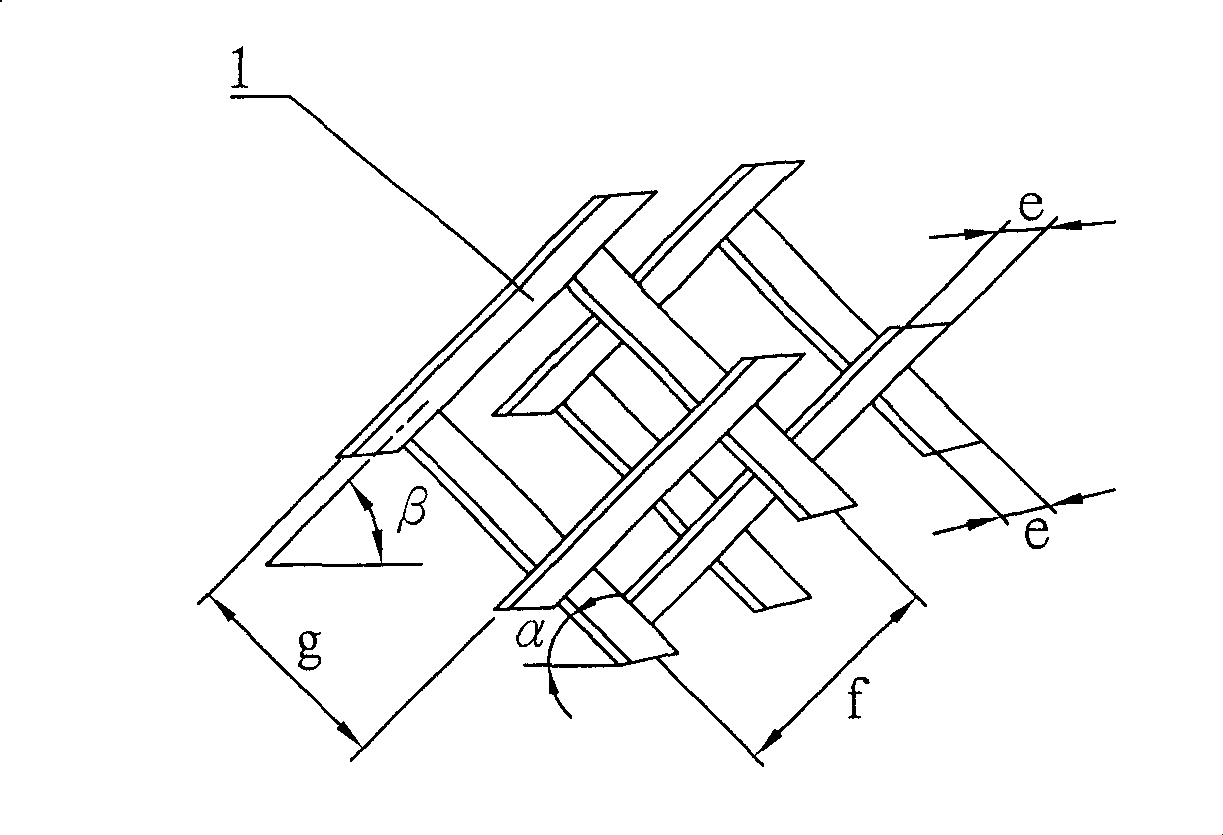

[0043] The fluidized bed gas-solid contact device of the present invention is used as an external riser type FCC device stripper for stripping the spent catalyst entrained with oil and gas from the settler. This embodiment adopts as Figure 6 The shown fluidized bed gas-solid contact equipment, its structure and operation process refer to Figure 6 related instructions. The parameters of the packing layer are shown in Table 1; the symbols of the structural parameters in Table 1 (and Table 2 of Example 2 and Table 3 of Example 3 below) are shown in Table 1. Figure 1 to Figure 5 and related instructions.

[0044] The FCC device is a conventional external riser type FCC device, the density of the processed raw oil is 923.6 kg / m3 (20°C), and the carbon residue is 4.04w%. The catalyst used is MLC-500 FCC catalyst. The top pressure of the settler is 0.16MPa, and the temperature is 500°C. The pressure of the primary and secondary stripping steam (steam) of the fluidized bed gas...

Embodiment 2

[0047] The fluidized bed gas-solid contacting equipment of the present invention is used as a stripper of an HCC device, and is used for stripping the regenerated catalyst entrained with gas impurities. This embodiment adopts as Figure 7 The shown fluidized bed gas-solid contact equipment, its structure and operation process refer to Figure 7 related instructions. The packing layer parameters are shown in Table 2.

[0048] The raw material oil processed by the HCC device has a density of 890 kg / m3 (20°C) and a carbon residue of 3.68w%. The catalyst used is LCM-5HCC catalyst. The top pressure of the regenerator is 0.18MPa, and the temperature of the catalyst dense-phase bed is 650°C. The pressure of the primary and secondary stripping steam (water vapor) of the fluidized bed gas-solid contact equipment is 1.0MPa, the temperature is 250°C, and the stripping line speed is 0.12 m / s.

[0049] The regenerated catalyst from the regenerator entrained with gaseous impurities, th...

Embodiment 3

[0051] The fluidized bed gas-solid contact equipment of the present invention is used as a regenerator of an FCC device to perform intensive regeneration of the catalyst. This embodiment adopts as Figure 8 The shown fluidized bed gas-solid contact equipment, its structure and operation process refer to Figure 8 related instructions. The packing layer parameters are shown in Table 3.

[0052] The FCC device is a conventional external riser type FCC device, the density of the processed raw oil is 910.9 kg / m3 (20°C), and the carbon residue is 4.98w%. The catalyst used is CHZ-4 FCC catalyst. The top pressure of the regenerator is 0.121MPa, the temperature of the catalyst dense-phase bed is 650°C, and the gas linear velocity is 0.75 m / s.

[0053] The spent catalyst from the spent inclined tube had a carbon content of 1.2w% before regeneration. After being regenerated by the fluidized bed gas-solid contact equipment of the present invention, the carbon content of the regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com