Folding blade drive of a folding machine

A driving device, a technology of folding knives, applied in the direction of folding thin materials, transportation and packaging, thin material handling, etc. Accuracy adverse effects and other problems, to achieve the effect of reducing the number of steering components and the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

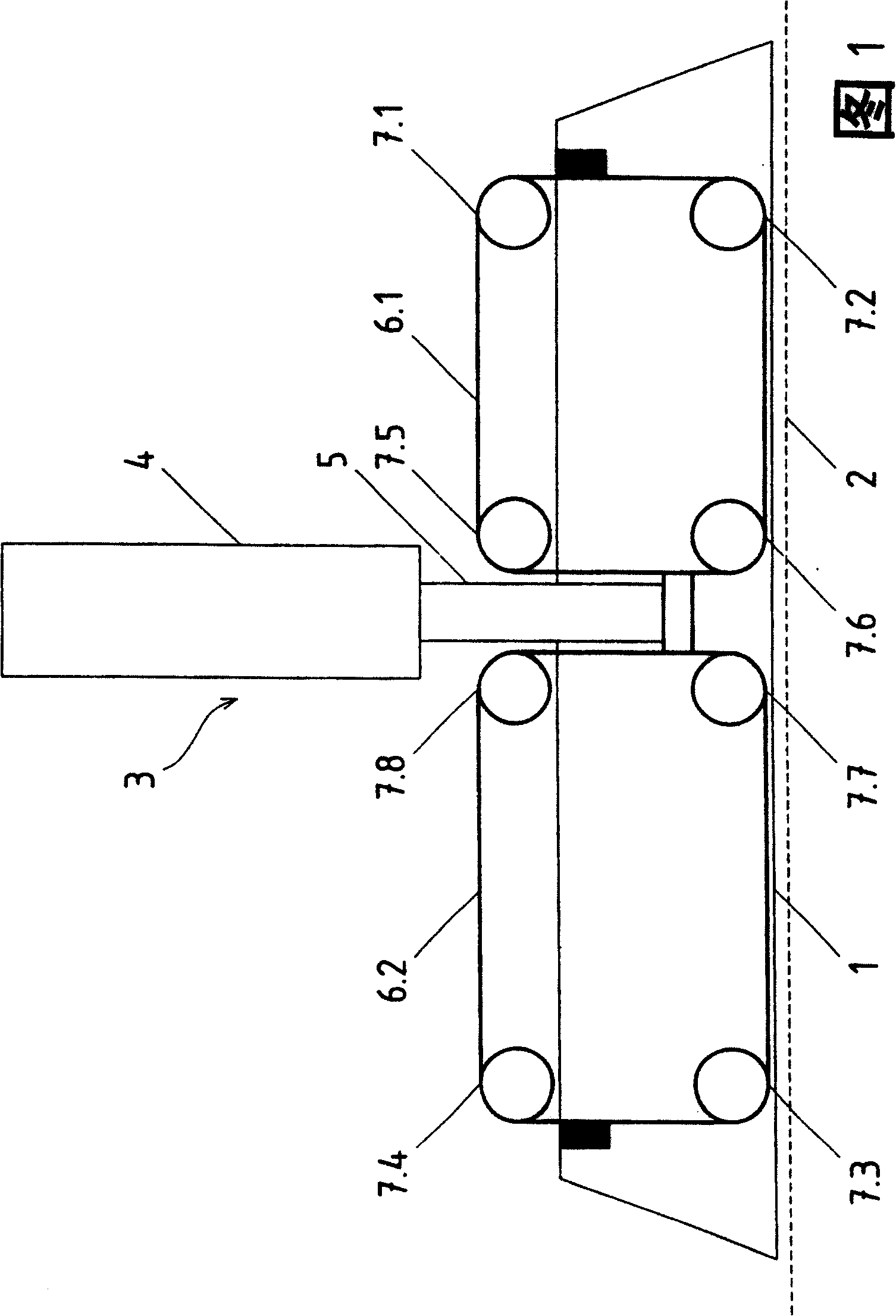

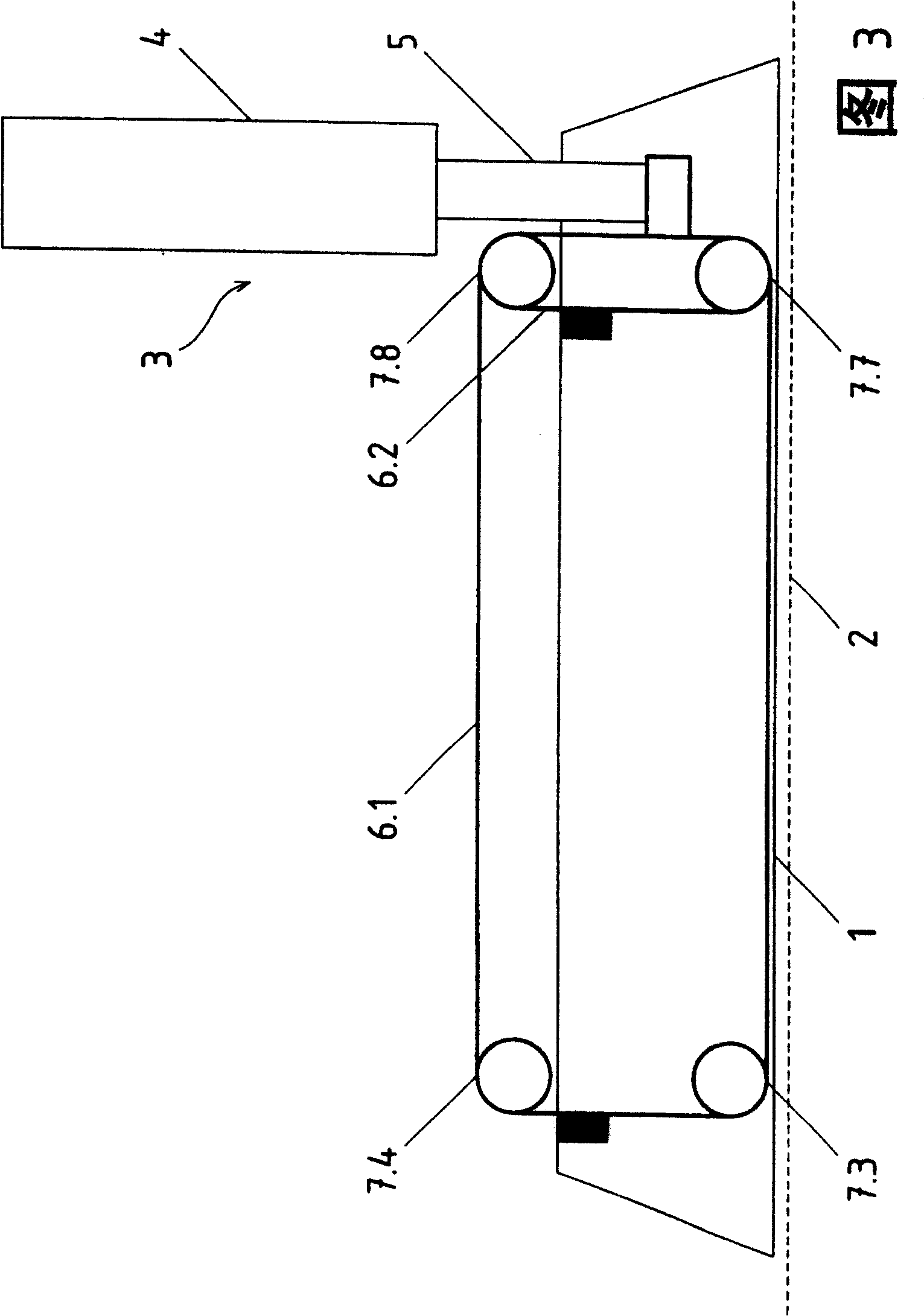

[0031]The folding knife drive shown in FIG. 1 is an integral part of a knife folding mechanism, in which the printed sheets guided by a not shown conveying system in the printed sheet plane 2 are transported by a pair of sheets arranged below the printed sheet plane 2. Rotating roller folding. The folding knife 1 presses the printed sheet into the gap formed between the rollers until the printed sheet is gripped by the rollers. For this purpose, the folding knife 1 is reciprocated between two end positions in a drive direction extending perpendicularly to the printed sheet plane 2 . The drive movement for driving the folding knife 1 is produced by a linear drive 3 designed as a linear motor, which comprises a linear drive stator 4 and a linear drive mover forming an output output unit 5 . The linear motor is arranged with its axis of motion extending approximately in the drive direction beyond the midpoint between the two ends of the folding knife 1 . On both ends of the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com