Method for processing split-type shaft system distribution oil ring

A processing method and split technology, applied in the processing field of split shaft oil distribution rings, can solve the problems of low quality, impossibility of casting Babbitt alloy, complicated processing technology, etc., and achieve simple processing technology and low manufacturing cost , to overcome the effect of uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

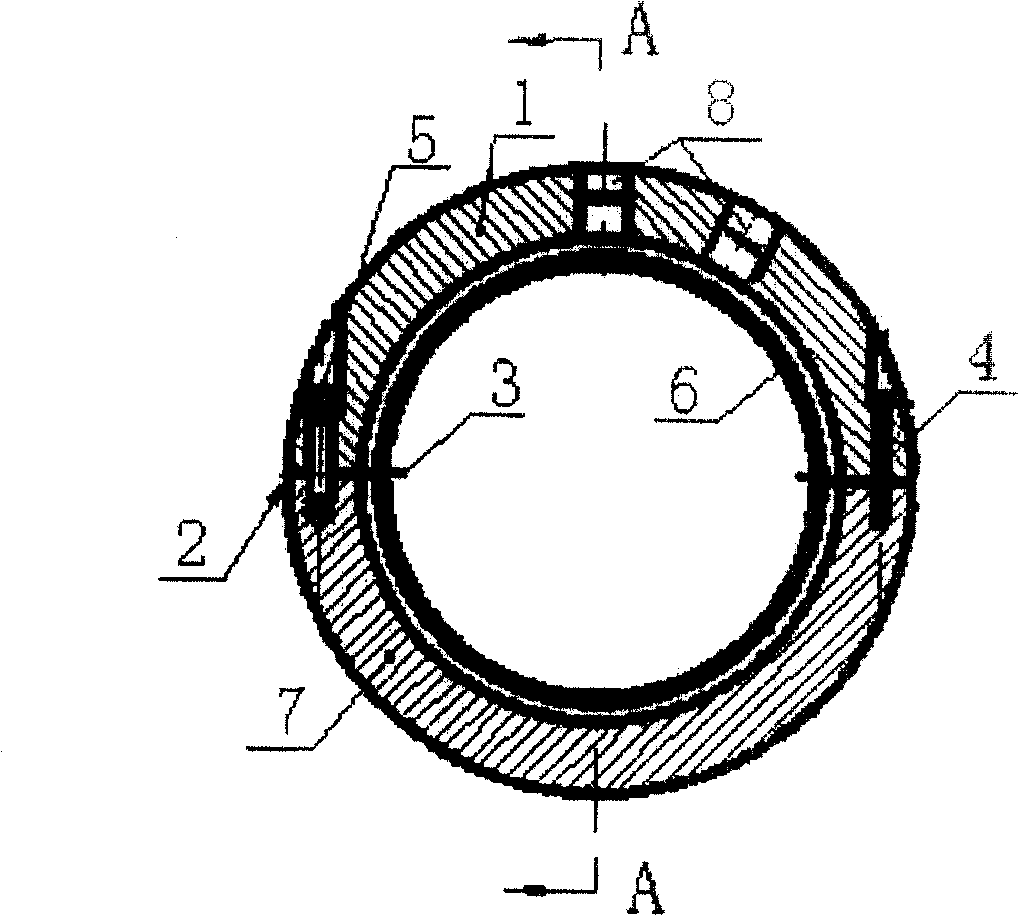

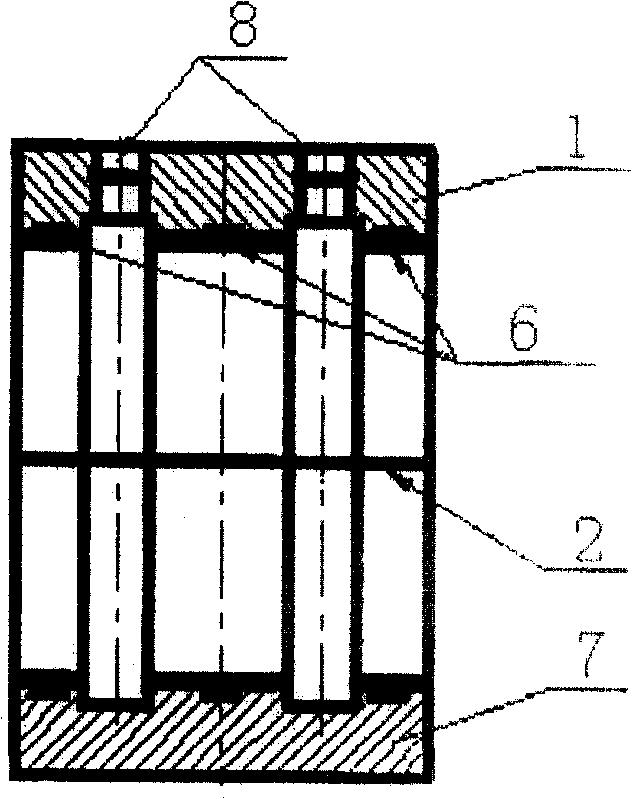

[0025] The processing method of the split shaft oil distribution ring comprises the following steps:

[0026] A. Use forging or casting to process the blanks of the upper half ring 1 and the lower half ring 7, first mill the half surface 2 on the blank, and the roughness of the half surface 2 after milling can be Ra=3.2 , with a flatness of 0.03 mm. Synthesize the blanks of the upper half ring 1 and the lower half ring 7 into a circular ring, spot weld the outer wall of the Huff surface 2 to form a complete ring, and then roughly machine the outer circle, end face, inner hole and Babbitt groove;

[0027] B. Drill bolt holes 4 on one side of the upper half ring 1 of the whole ring after rough machining and tap the corresponding holes on the lower half ring 7, and drill and ream on the other side of the upper half ring 1 of the whole ring Make positioning pin hole 5;

[0028] C. Manually use a chisel or a file to disassemble the solder joints on the entire ring, separate the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com