Rear-projection screen, optical element and manufacturing method thereof

A technology of optical components and manufacturing methods, applied to the optical components of rear projection screens and its manufacture, and in the field of rear projection screens, can solve the problems of brightness reduction, limitation of contrast and resolution, thickness tolerance, etc., and achieve increased area, contrast and The effect of improving the resolution and increasing the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

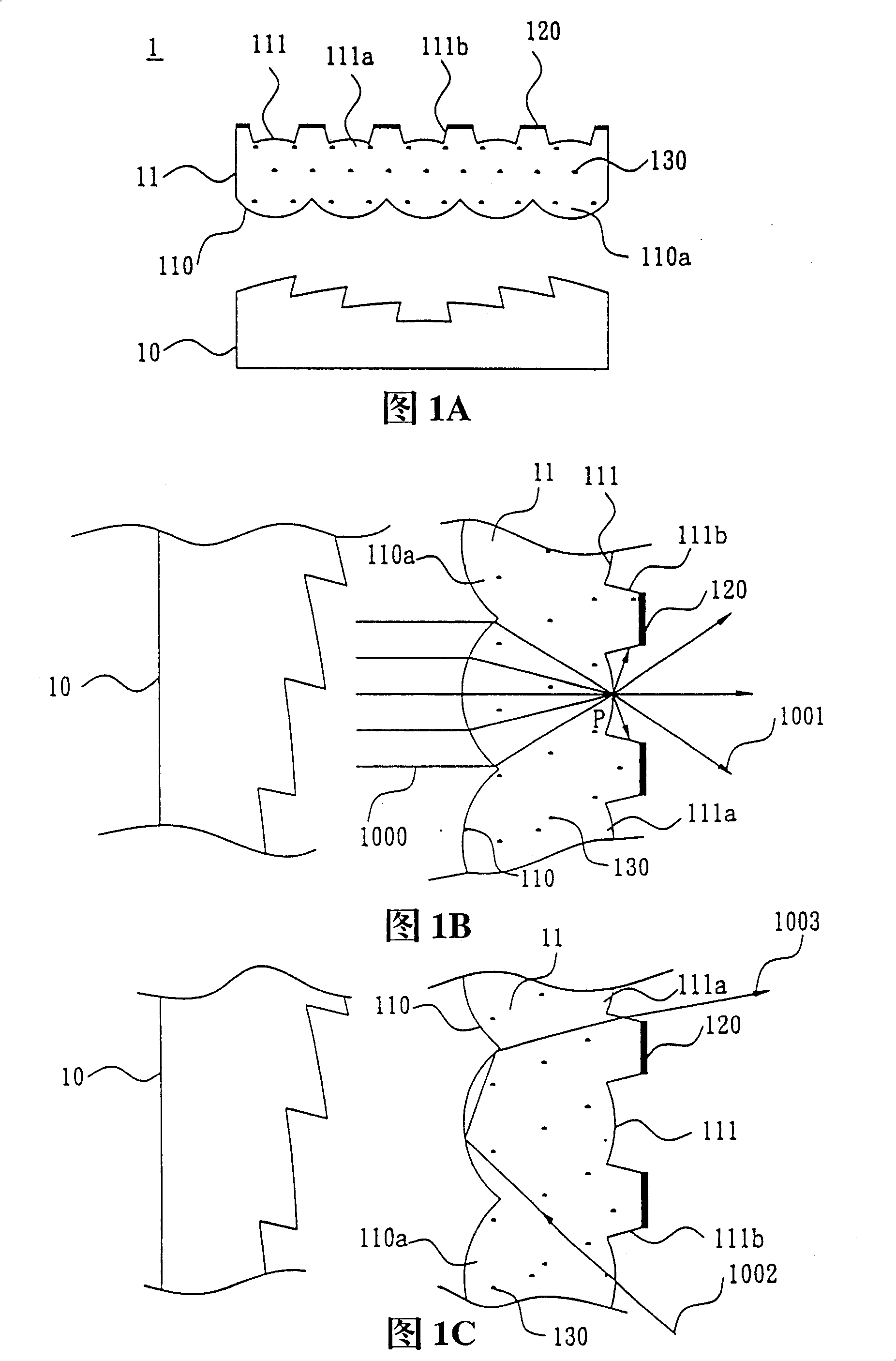

[0061] The rear projection screen according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same symbols.

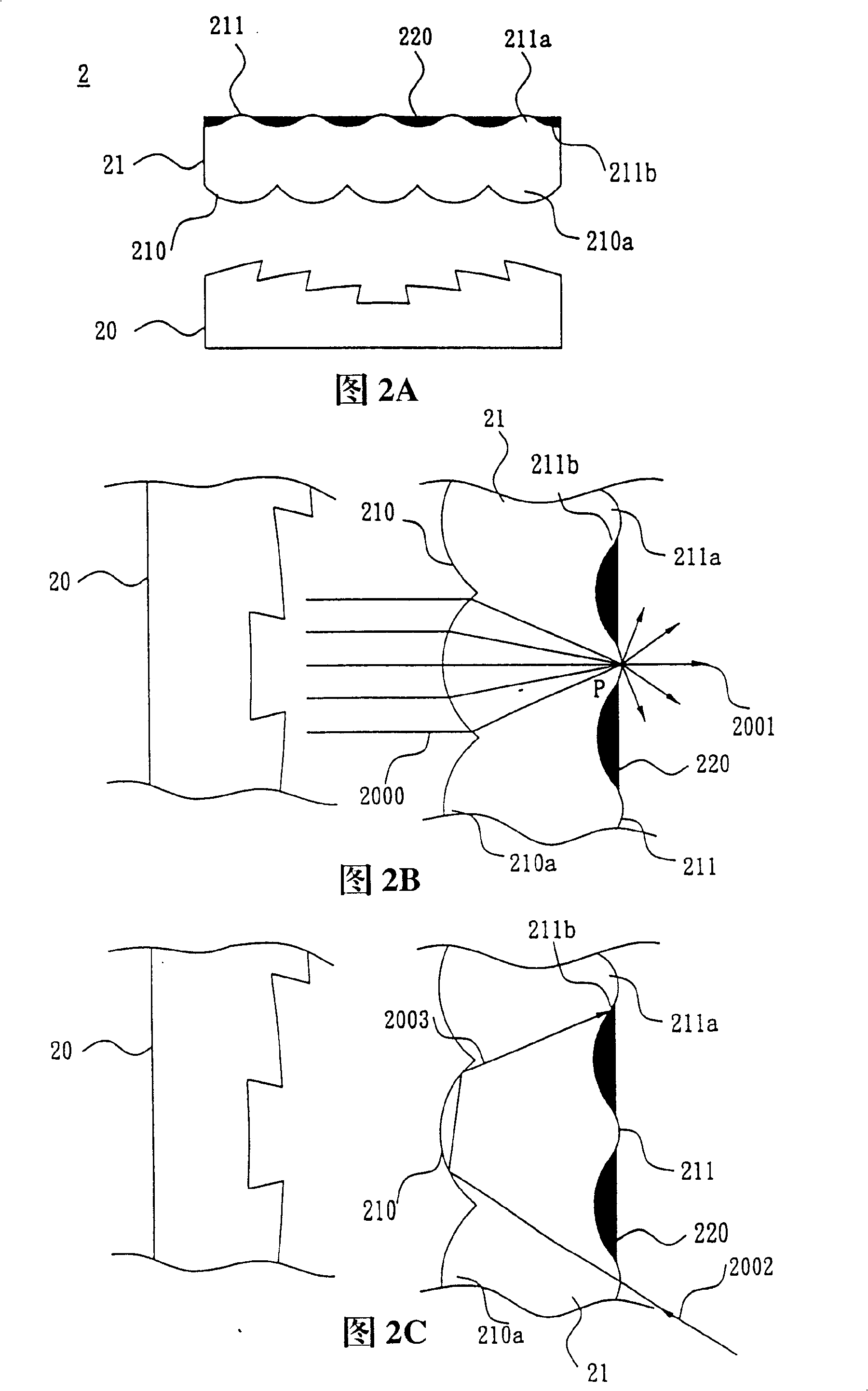

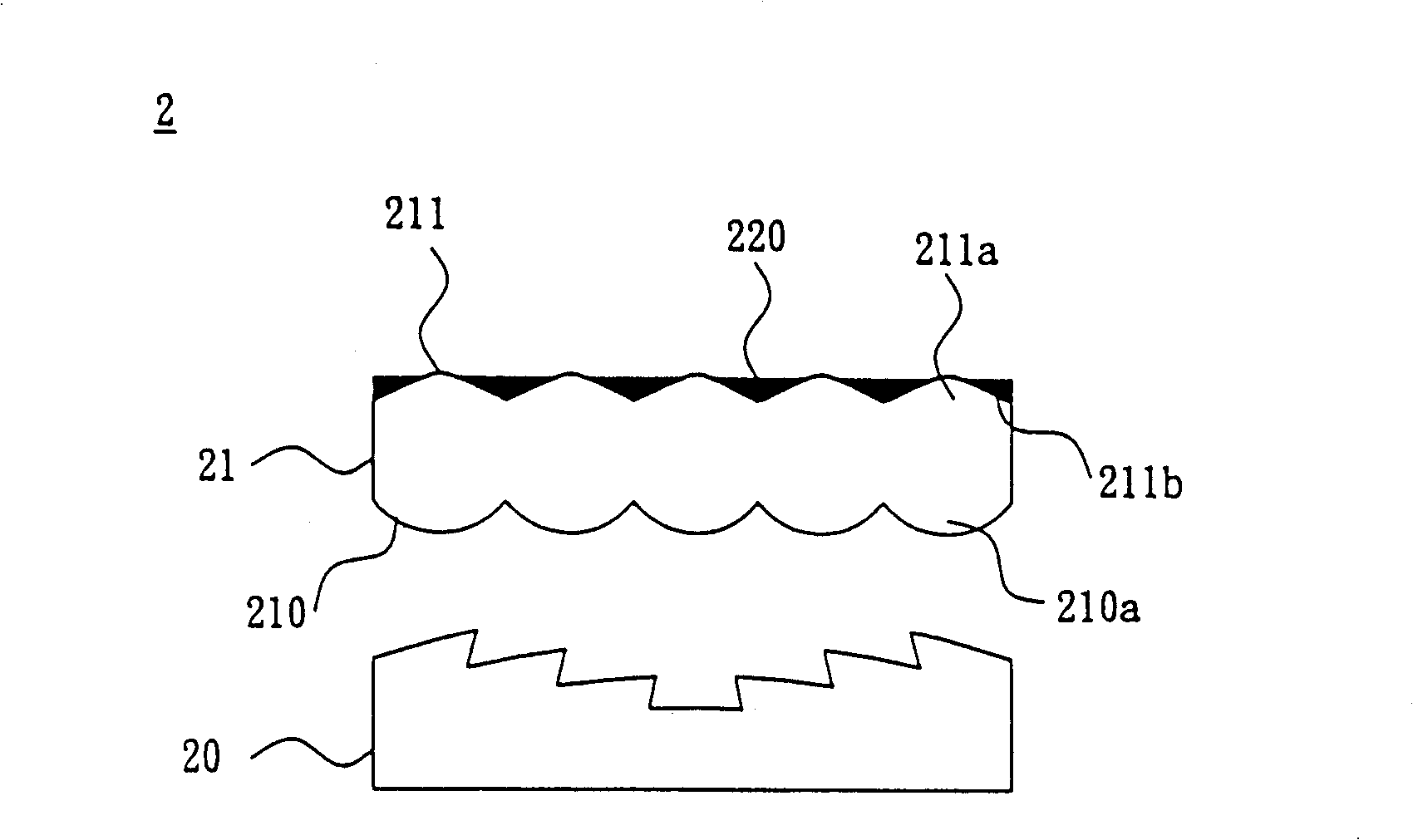

[0062]Please refer to Figures 2A, 2B and 2C (Figures 2B and 2C are partial enlarged views of Figure 2A), the rear projection screen 2 according to a preferred embodiment of the present invention includes a first optical element 20 and a second optical element 21 .

[0063] The first optical element 20 is used to collect light, so that originally divergent light can be collected and entered into the viewer's sight. In this embodiment, the first optical element 20 is a Fresnel lens. In this way, the light rays can be collected and exit the Fresnel lens in a parallel manner.

[0064] The second optical element 21 has a first surface 210 and an opposite second surface 211, the first surface 210 is adjacent to the first optical element 20, and the first surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com