Waste heat boiler

A technology of waste heat boiler and waste gas flow, which is applied in the direction of heat exchange equipment, heat exchanger type, indirect heat exchanger, etc., can solve the problems of waste heat boiler life reduction, shortened maintenance cycle, hot spots on the wall of exhaust chamber, etc., and achieve improvement The effect of service life, improvement of function and life, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

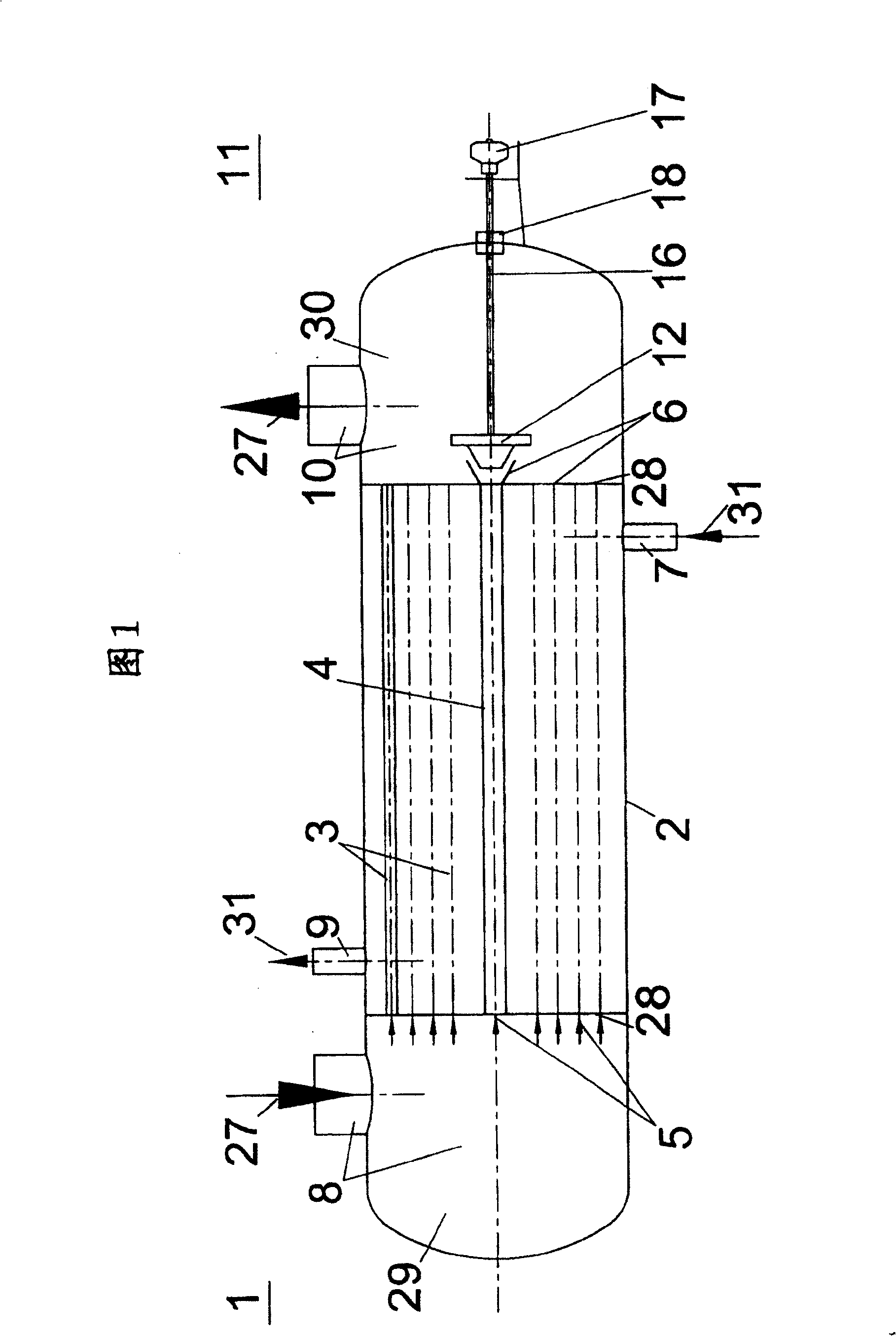

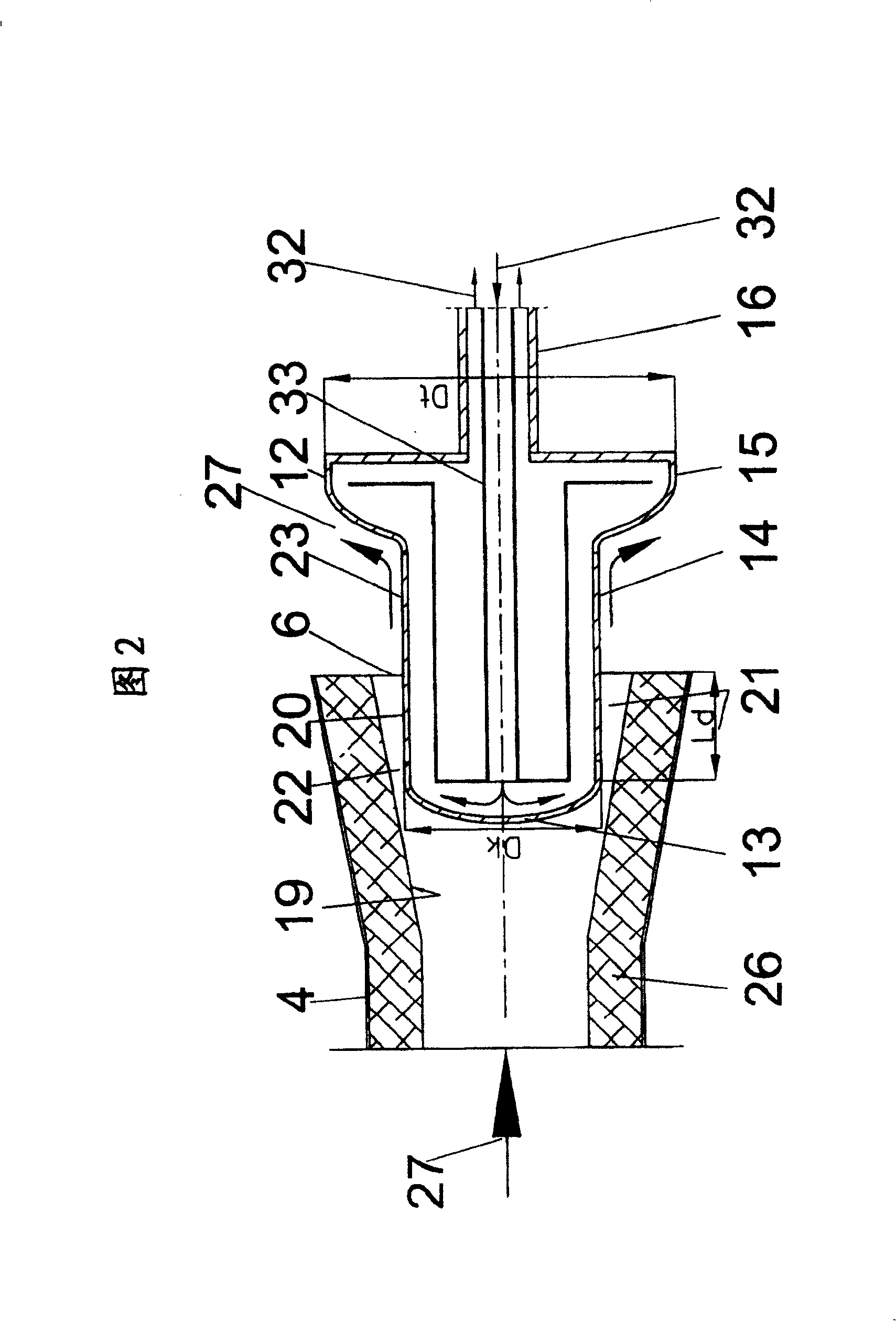

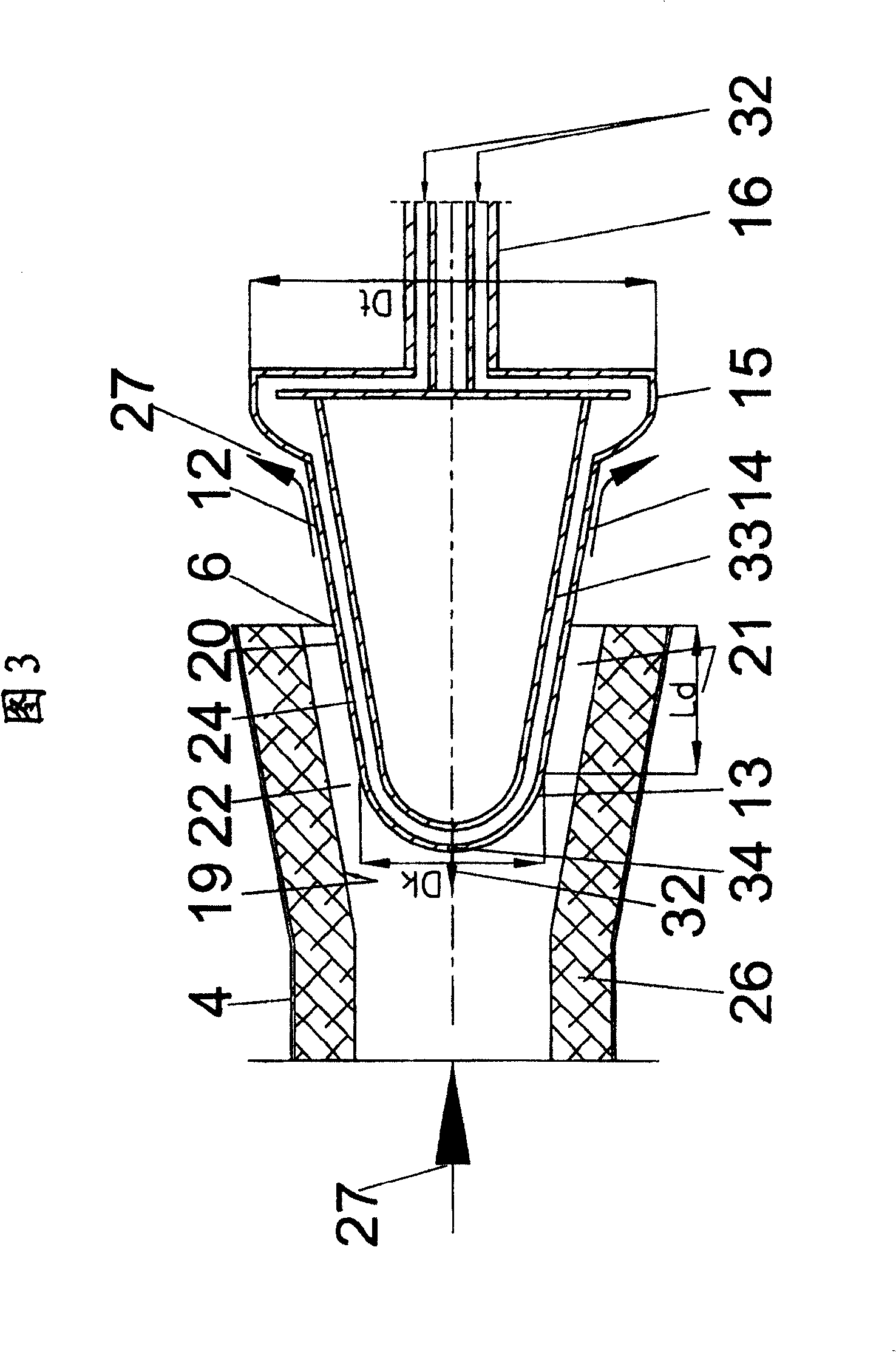

[0024] FIG. 1 schematically shows a waste heat boiler 1 in longitudinal section. Such waste heat boilers are required for different chemical and petrochemical processes. The waste heat boiler 1 has a casing 2 which encloses a large number of heat transfer tubes 3 and a centrally arranged bypass tube 4, wherein the tubes 3, 4 are surrounded at their inlet and outlet ends 5, 6 by tube end plates 28 such that A cavity for conducting a cooling medium 31 for cooling the high-temperature exhaust gas flow 27 is formed in the housing 2 and the end plate 28 . The bypass pipe 4, which preferably has a larger diameter than the heat transfer pipe 3, can be partially or completely insulated over its length, so that the sometimes very high temperature exhaust gas 27 on the bypass pipe 4 cannot be conveyed too much to the cooling medium 31 The heat flows through the waste heat boiler 1. Viewed along the flow direction of the exhaust gas 27, that is, parallel to the longitudinal axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com