New type heater for roughcast of plastic bottle

A technology for a plastic bottle and a heater, which is applied to the field of heaters for plastic preforms, can solve the problems of troublesome disassembly and assembly of lamps, inability to heat the preforms in sections, etc., and achieves the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

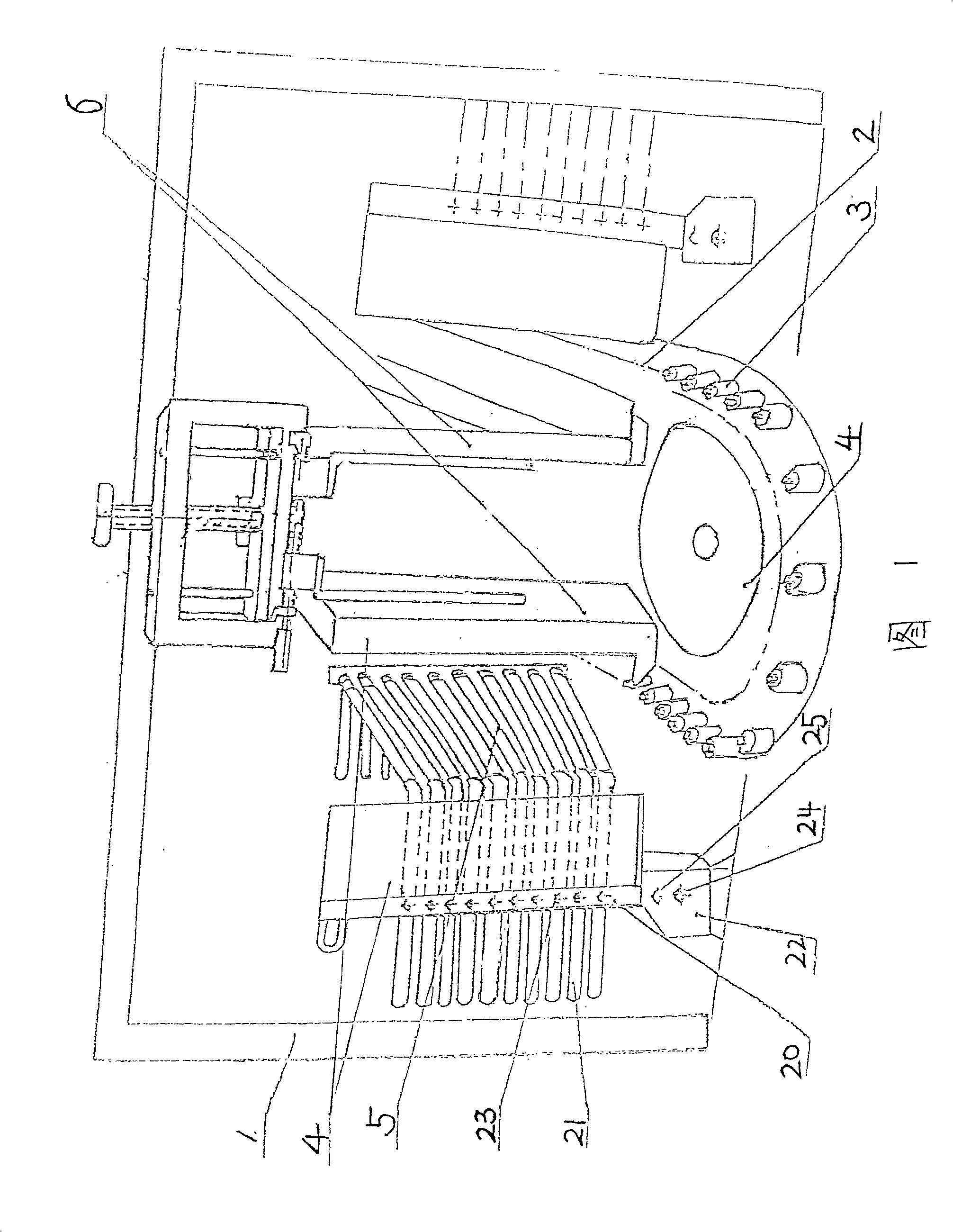

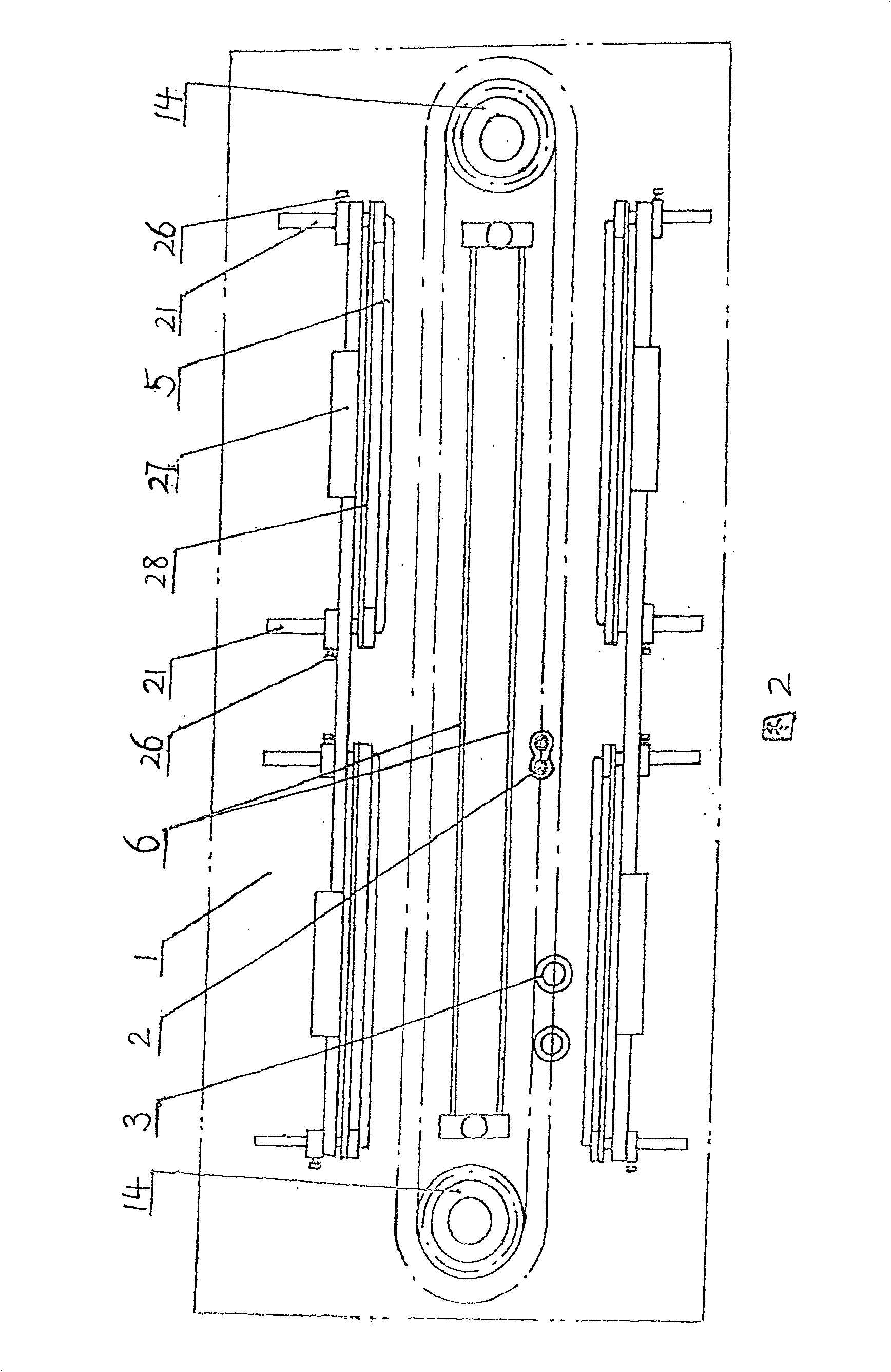

[0013] A plastic preform heater, including a frame 1, an endless chain 2 driven by a sprocket, a preform supporting seat 3 is arranged on the endless chain 2, the endless chain 2 passes through a heating device 4, and the heating device is composed of a heating lamp 5 Composed of reflector 6, the bracket 20 used to install the heating lamp 5 in the heating device 4 is hinged with the frame 1, the bracket 20 is the heating plate, the end of the heating lamp 5 is equipped with an adjustment rod 21, and the lamp forms shape, the adjusting rod 21 is movably assembled with the support 20. Each lamp tube is provided with an adjusting rod 21, and the bracket 20 is divided into a base 22 and a vertical rod 23. The base 22 is fixed on the workbench of the frame 1, and a connecting pin 24 and a fixed bolt are arranged between the vertical rod 23 and the base 22. 25. When the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com