Flexible soft tube

A flexible, flexible hose technology, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of reducing air barrier and difficult to ensure flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

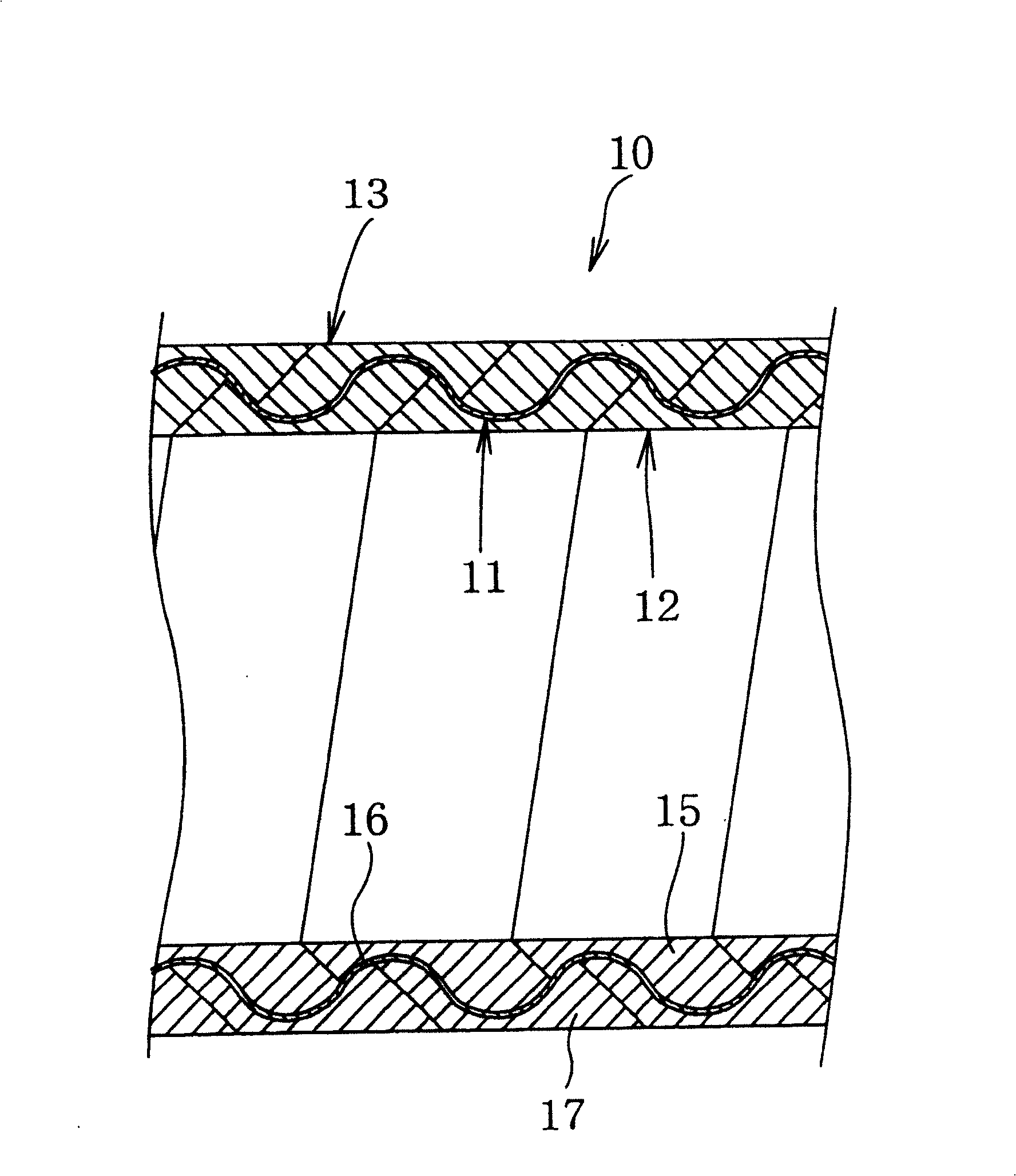

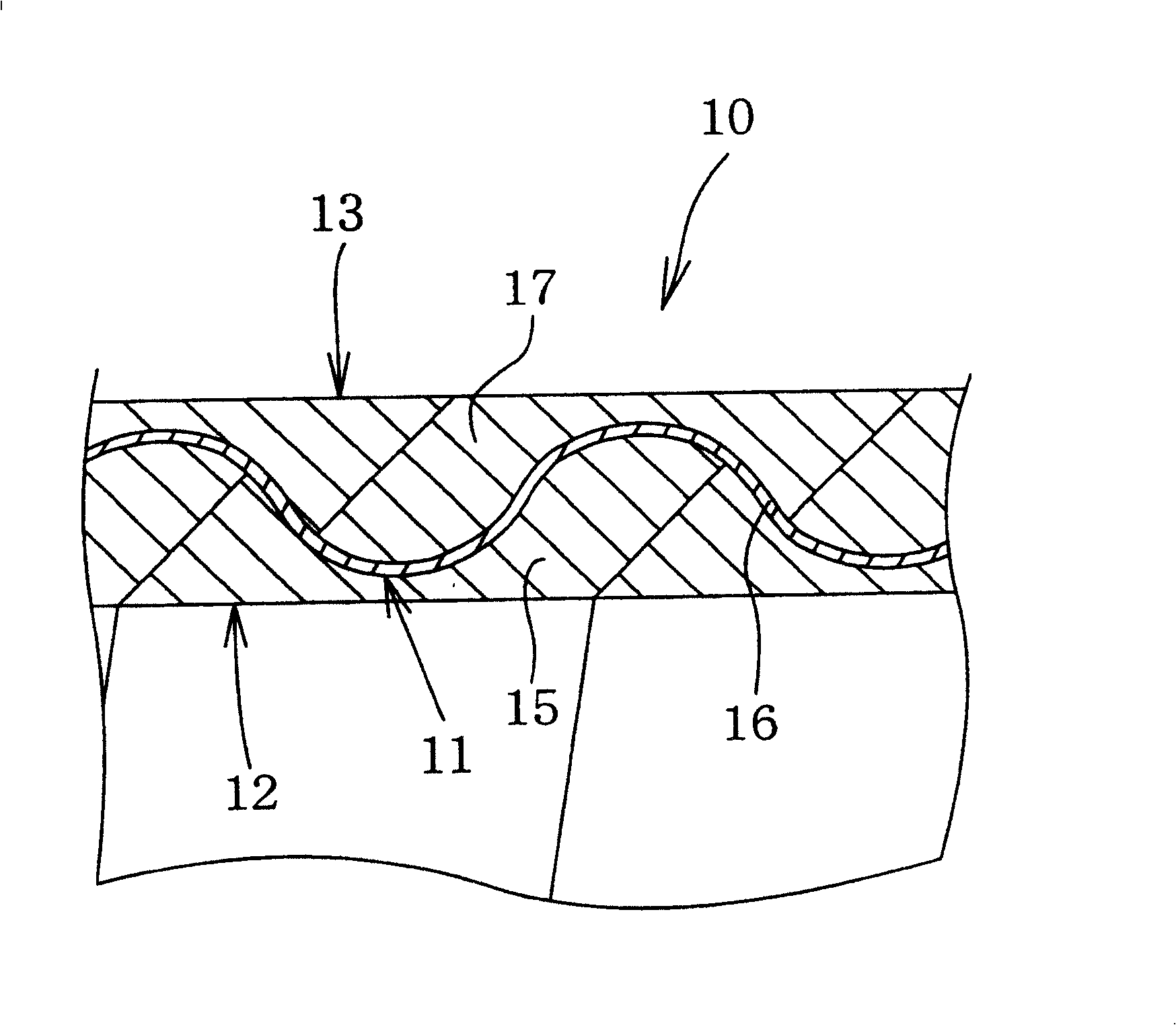

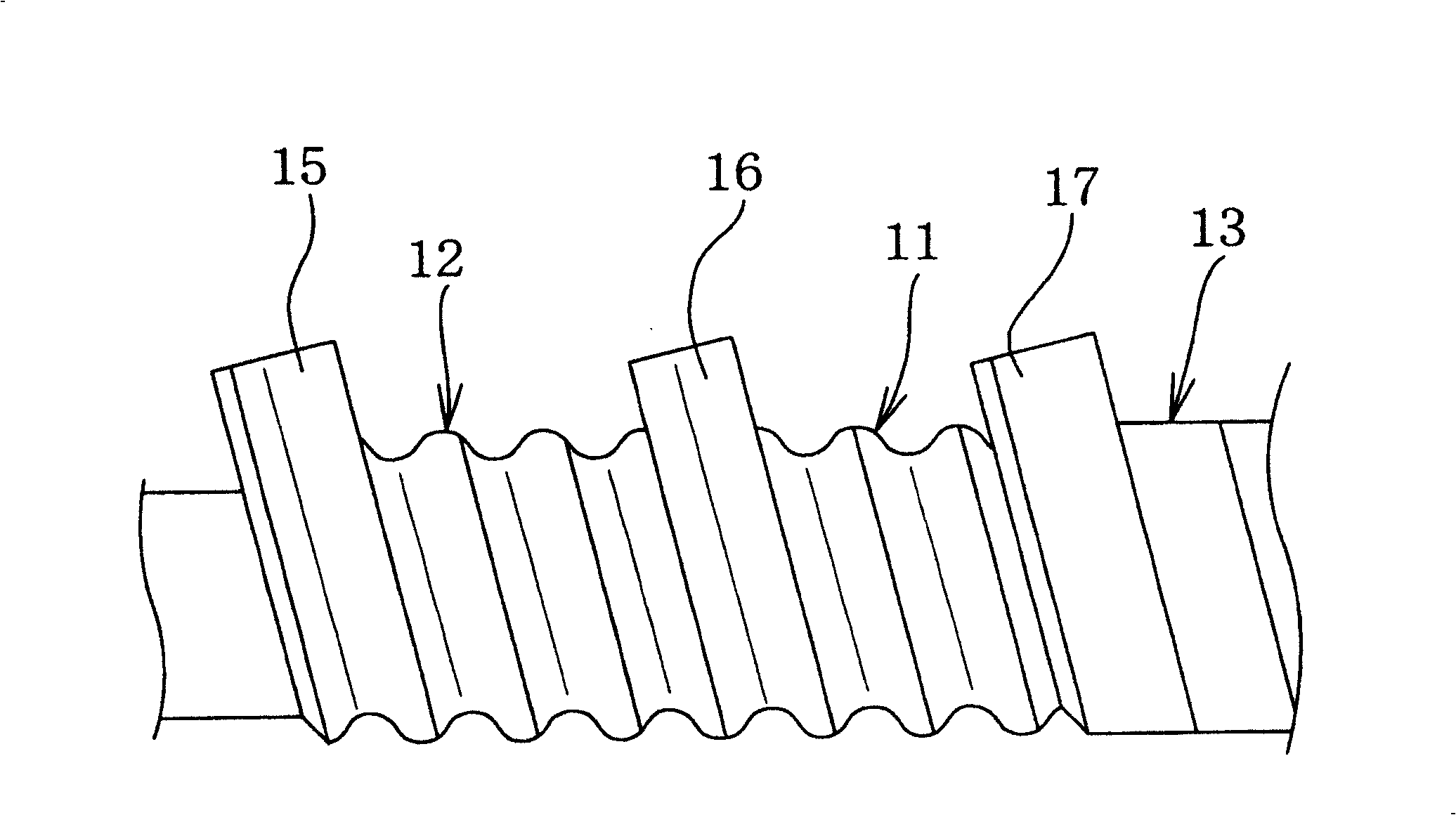

[0022] Embodiments of the present invention will be described in detail below based on the drawings. Such as figure 1 as well as figure 2 As shown, in the flexible hose in one embodiment of the present invention, the middle resin layer 11 is pinched in the inner and outer resin layers 12, 13 and these resin layers 11, 12, 13 are laminated in the radial direction. into the hose wall 10.

[0023] The intermediate resin layer 11 is a hard gas-barrier layer formed of a resin with gas-barrier properties, such as nylon 6, to ensure the rigidity and shape retention of the hose. The intermediate resin layer 11 has a certain thickness, and forms a concavo-convex continuous wave along the axial direction. Therefore, good flexibility is maintained without impairing the gas barrier properties. In addition, although the intermediate resin layer 11 is formed with concavities and convexities on both its inner and outer peripheral surfaces, it is also possible to form continuous concavo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com