Electric green fence shearing machine with speed changing structure

A hedge trimmer and variable speed structure technology, applied in the field of electric hedge trimmers, can solve problems such as unsolvable problems and inconvenient use, and achieve the effects of easy operation and portability, reasonable combination, and easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

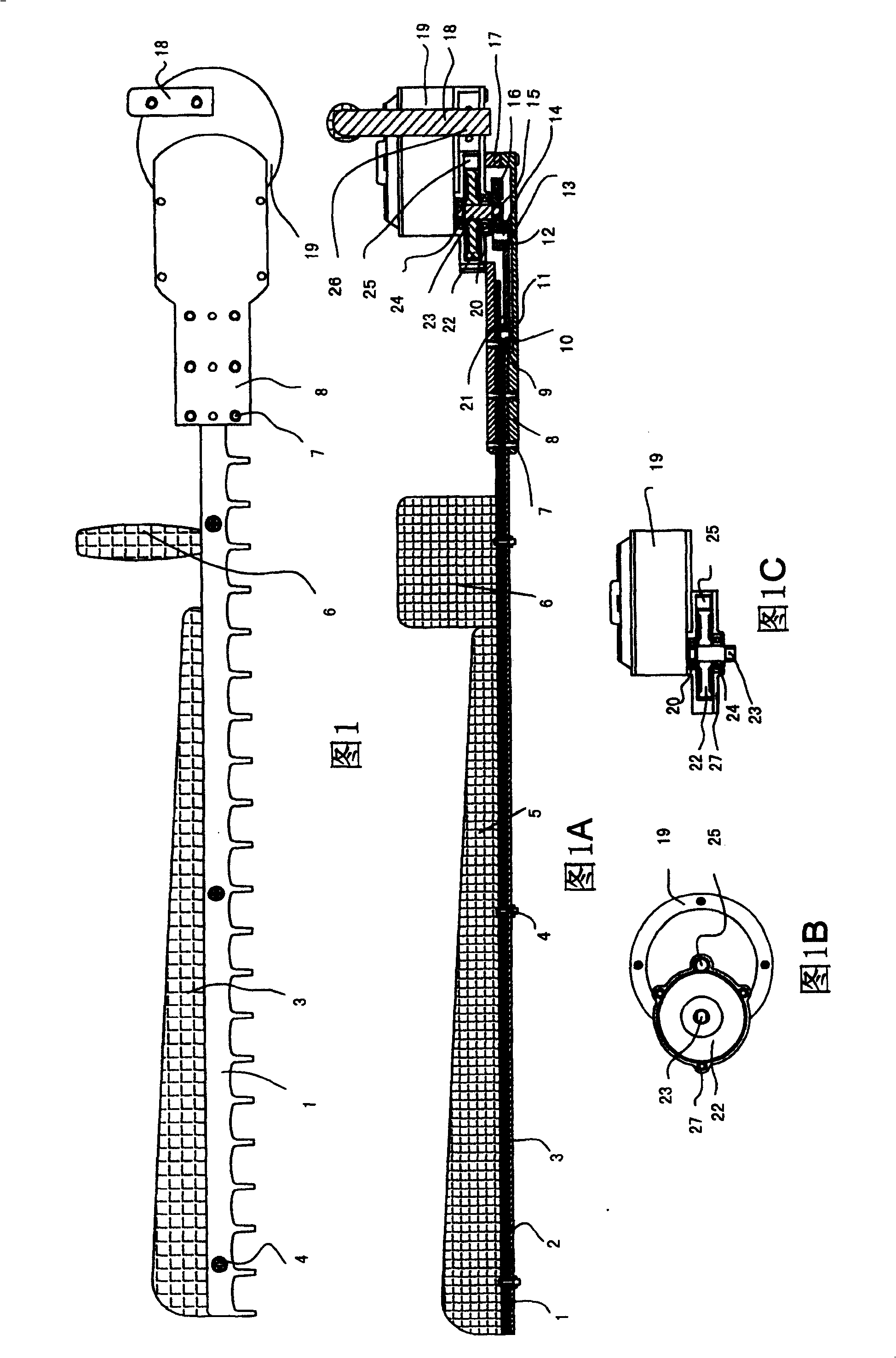

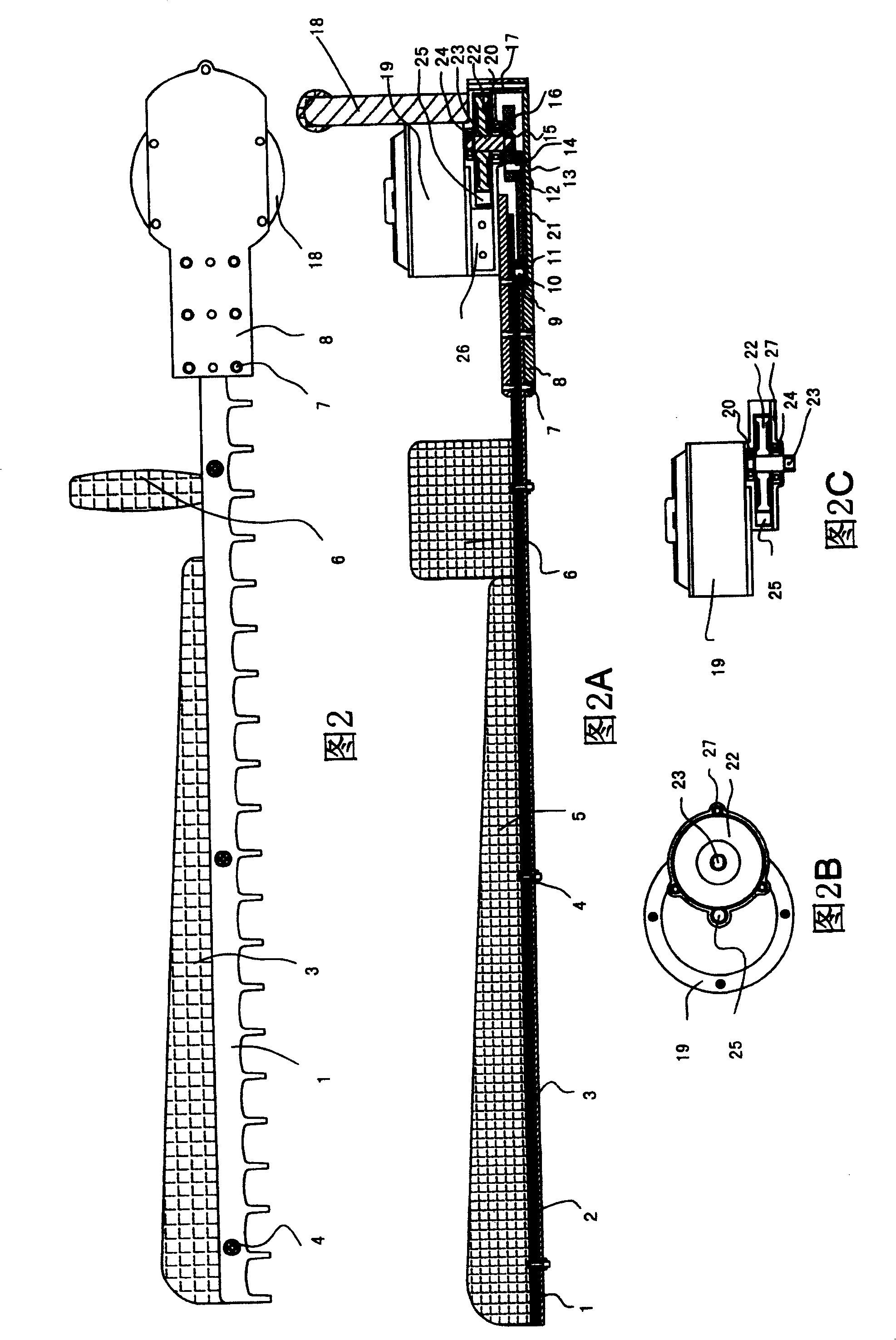

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] As shown in Figures 1 to 2C, the electric hedge trimmer with a variable speed structure includes an electric hedge trimmer with a variable speed structure, including a chassis assembled from a bottom cover 8 and an upper cover 27 and having an inner cavity, the inner cavity of the chassis The front end of the front end is equipped with a tooth bottom plate 1, a tooth movement plate 2, and a guide positioning plate 3 that cooperate with each other; it is characterized in that: a motor assembly including a micro motor 19 and a controller 26 is installed on the outer side of the chassis; the motor shaft 25 extends A helical gear extends into the inner cavity of the rear end of the case at the outlet, and meshes with the helical gear 22 in the inner cavity of the case; the helical gear 22 is connected to the pinion shaft 23, and the first en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com