Laser holographic coining press and laser holographic coining technique

A technology of laser holography and molding presses, which is applied in the direction of stamping, printing machines, rotary printing machines, etc., and can solve the problems of low temperature requirements for plate rolls and too high plate roll temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

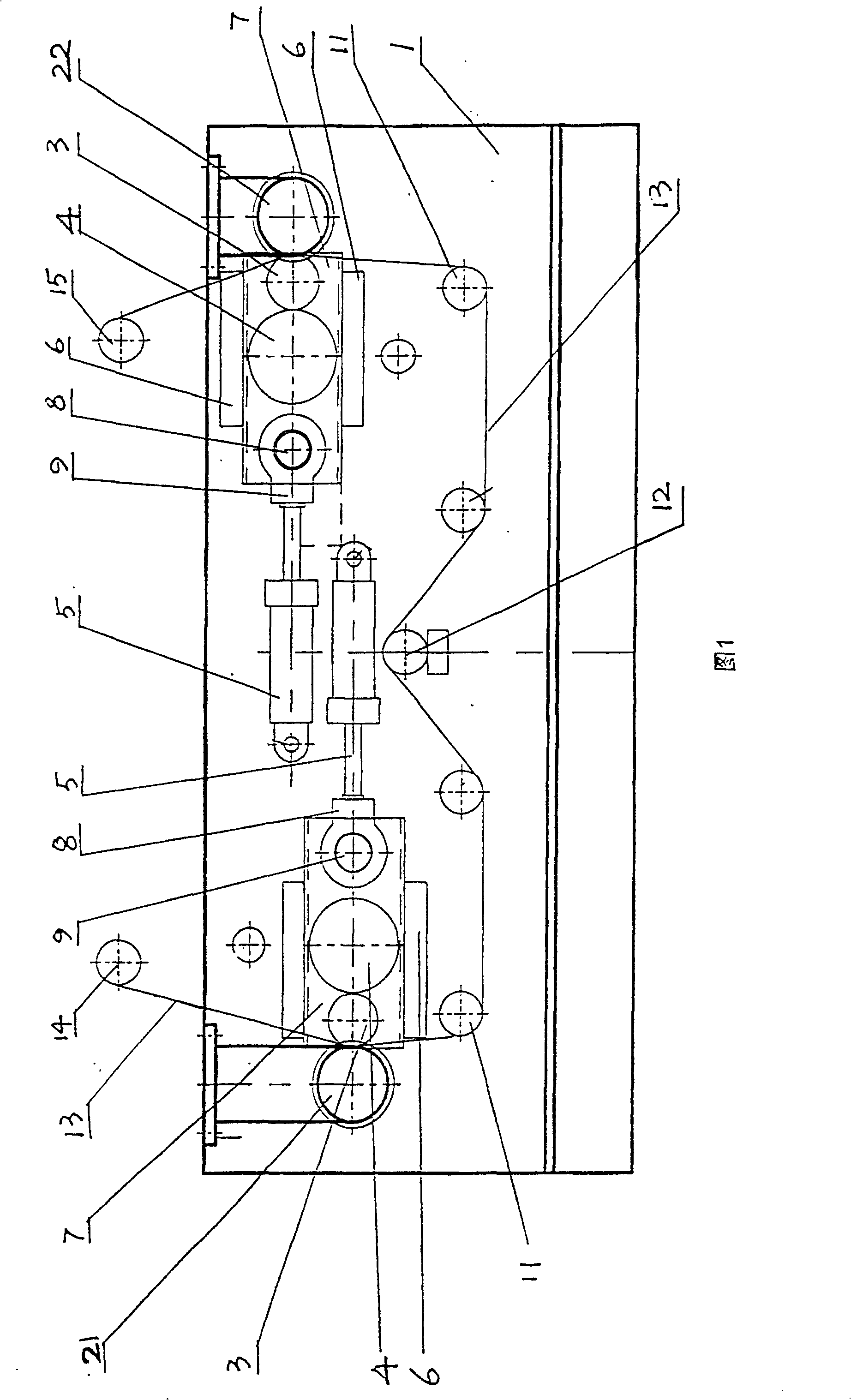

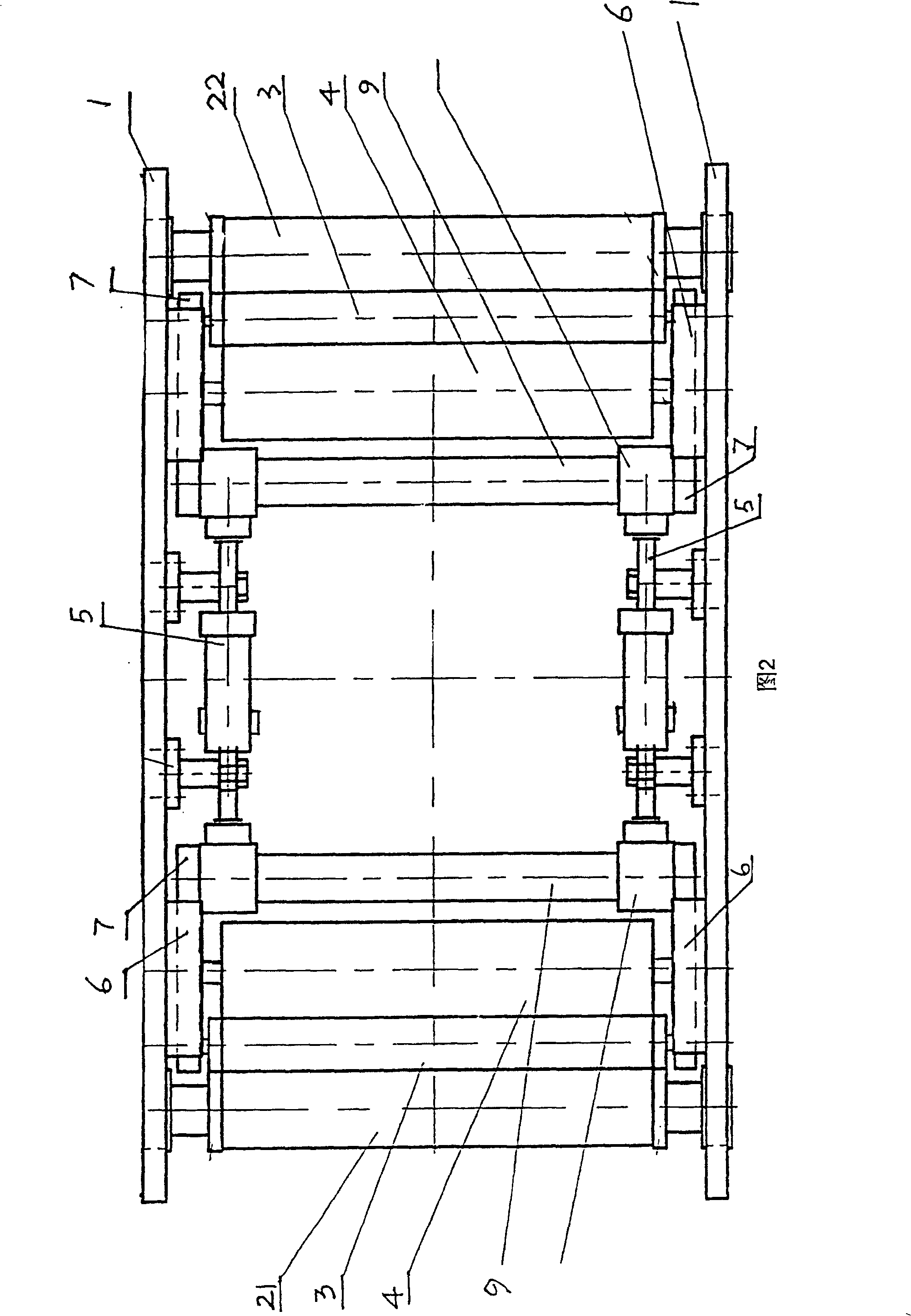

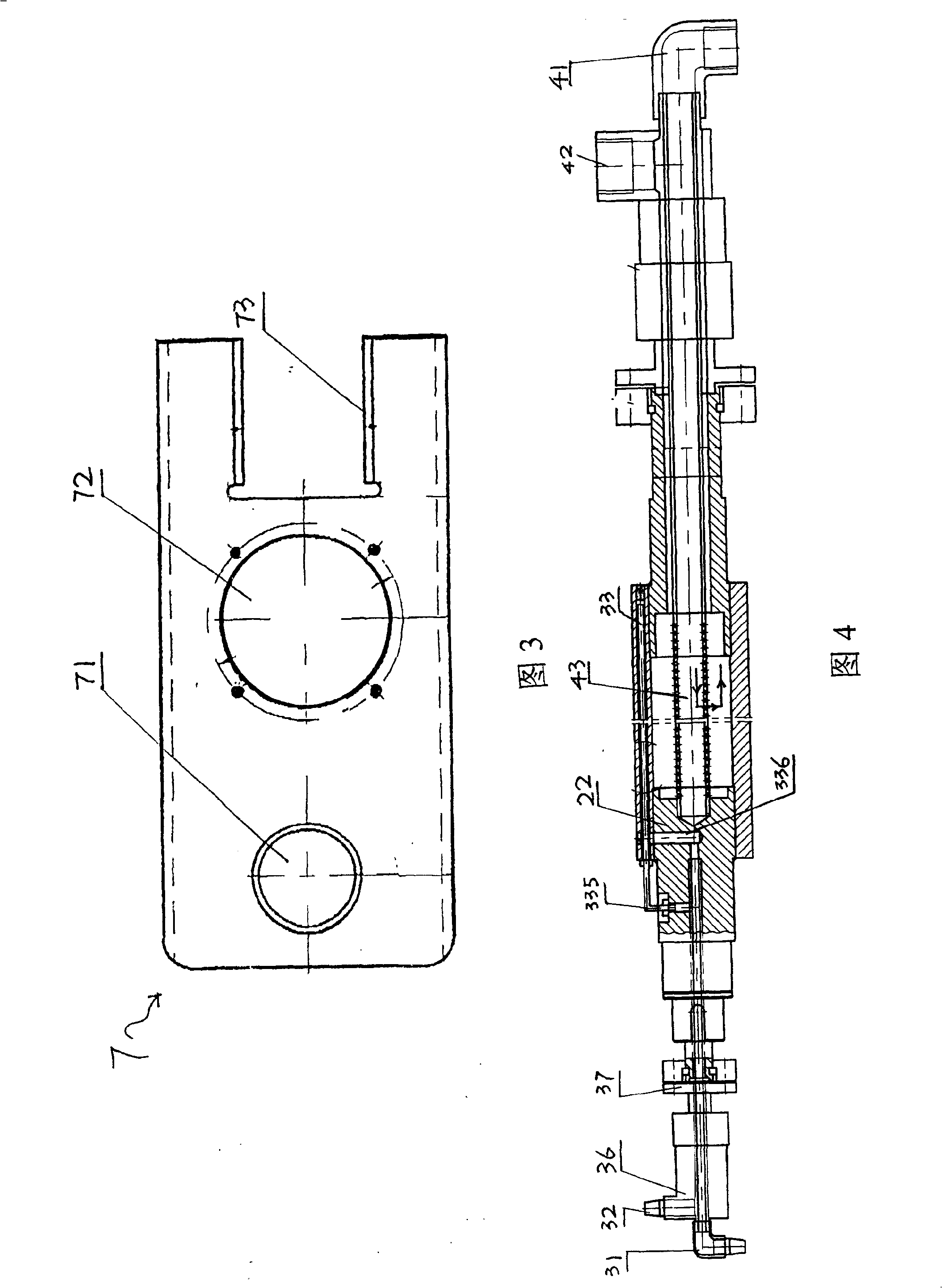

[0027]As shown in Figure 1, Figure 2, and Figure 3, the laser holographic molding machine includes a frame 1, on which the first molding station and the second molding upper position are installed, and the first molding station is provided with a plate roller 21. The second molding station is equipped with a version roller 22, and a thermal oil internal circulation heating device is installed in the version roller; each molding station is provided with a backing roller 3, a pressing roller 4, and an oil cylinder 5, and the pressing roller 4 is provided with a Cooling water circulation cooling device, the lining roller 3 is a rubber roller, the rubber roller 3 is installed between the version roller 2 and the pressure roller 4, the two ends of the version roller are fixed on the frame, and the left and right sides of the frame are respectively equipped with Horizontal guide rail 6, slide plate 7 is installed respectively on the horizontal guide rail 6 of both sides, as shown in ...

Embodiment 2

[0033] The laser holographic molding process shown in Fig. 1 adopts the laser holographic molding machine described in Embodiment 1, comprising the following steps:

[0034] a. The molding manufacturer rolls and pastes the metal mold embossing plate 10 with the same laser dot matrix grating graphic information on the first plate roller 21 and the second plate roller 22 respectively, and the first plate roller forms a seam A of the metal mold embossing plate; A seam B of the metal mold embossing plate is formed on the second version roller; the seam B of the metal mold embossing plate on the second edition roller is aligned with the position of the cooling water flow channel, such as Figure 5 , Figure 6 shown;

[0035] b. Circularly transport hot oil to the first version roller through the hot oil pipeline, control the surface temperature of the first version roller at about 145°C, and carry out laser holographic embossing on the plastic film 13 at the first molding station. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com