Finite angle driving controller of direct-drive triple redundant brushless DC torque motor

A technology of DC torque motor and drive controller, which is applied in the direction of electric controller, electronic commutation motor control, computer control, etc. It can solve the problem of affecting system safety and reliability, affecting motor control performance, and weak anti-interference ability, etc. problem, to achieve the effect of meeting the real-time requirements of the system, enhancing anti-interference and reliability, and flexible and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

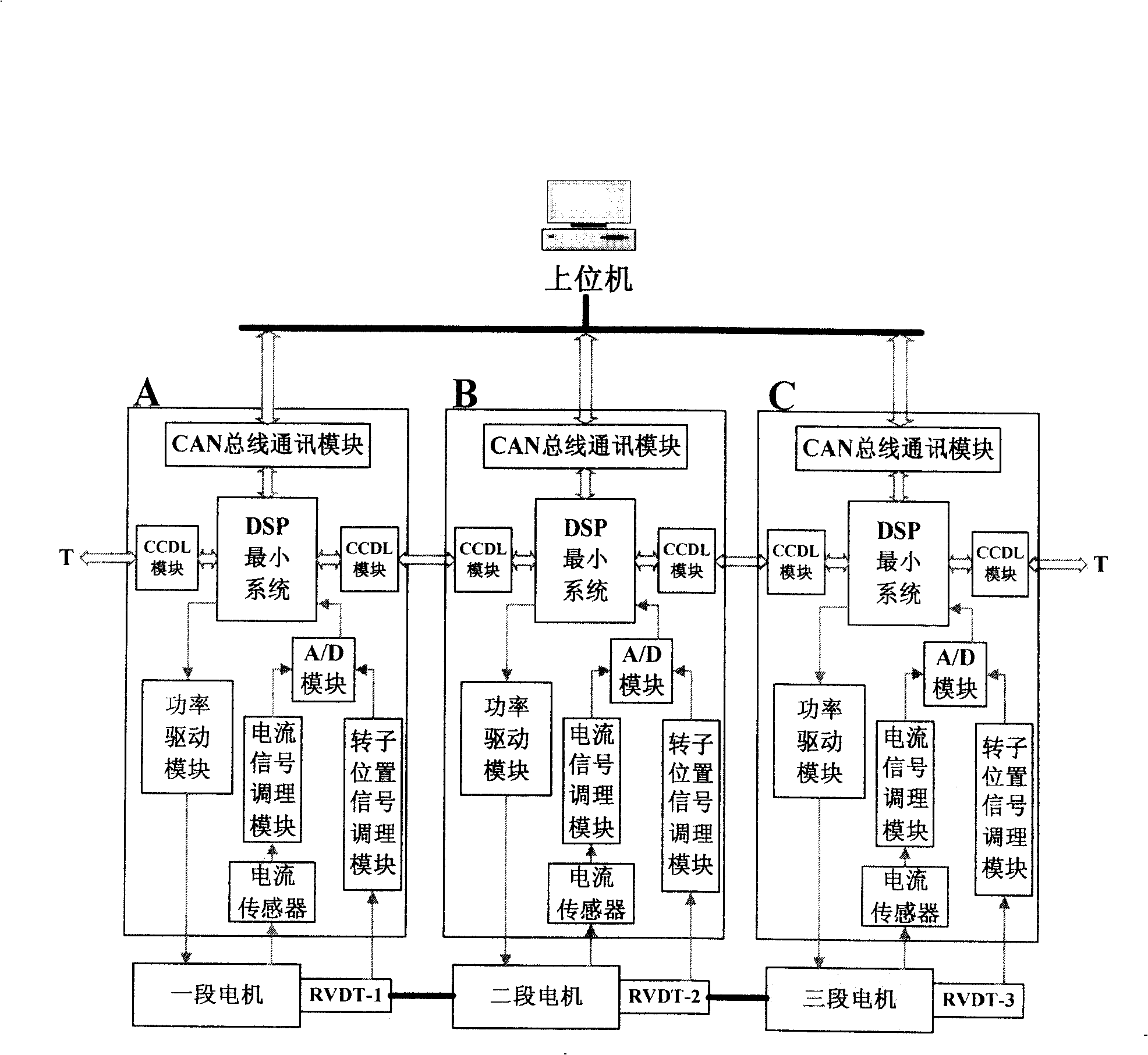

[0039] like figure 1 As shown, a kind of direct-drive type three-redundancy brushless DC torque motor limited angle drive controller of the present invention is made up of three identical channels; each channel is composed of a DSP minimum system, a CAN bus communication module, a CCDL module, The current signal conditioning module, the rotor position signal conditioning module, the A / D module, the power drive module, etc.; the three channels are connected by the CCDL module for data communication; the CAN bus communication module is used for data communication between each channel and the upper computer; each The channel is connected to the three-phase windings of each segment of the motor through the power drive module; the double closed-loop control of the position loop and current loop of the system is realized by using RVDT and current sensor.

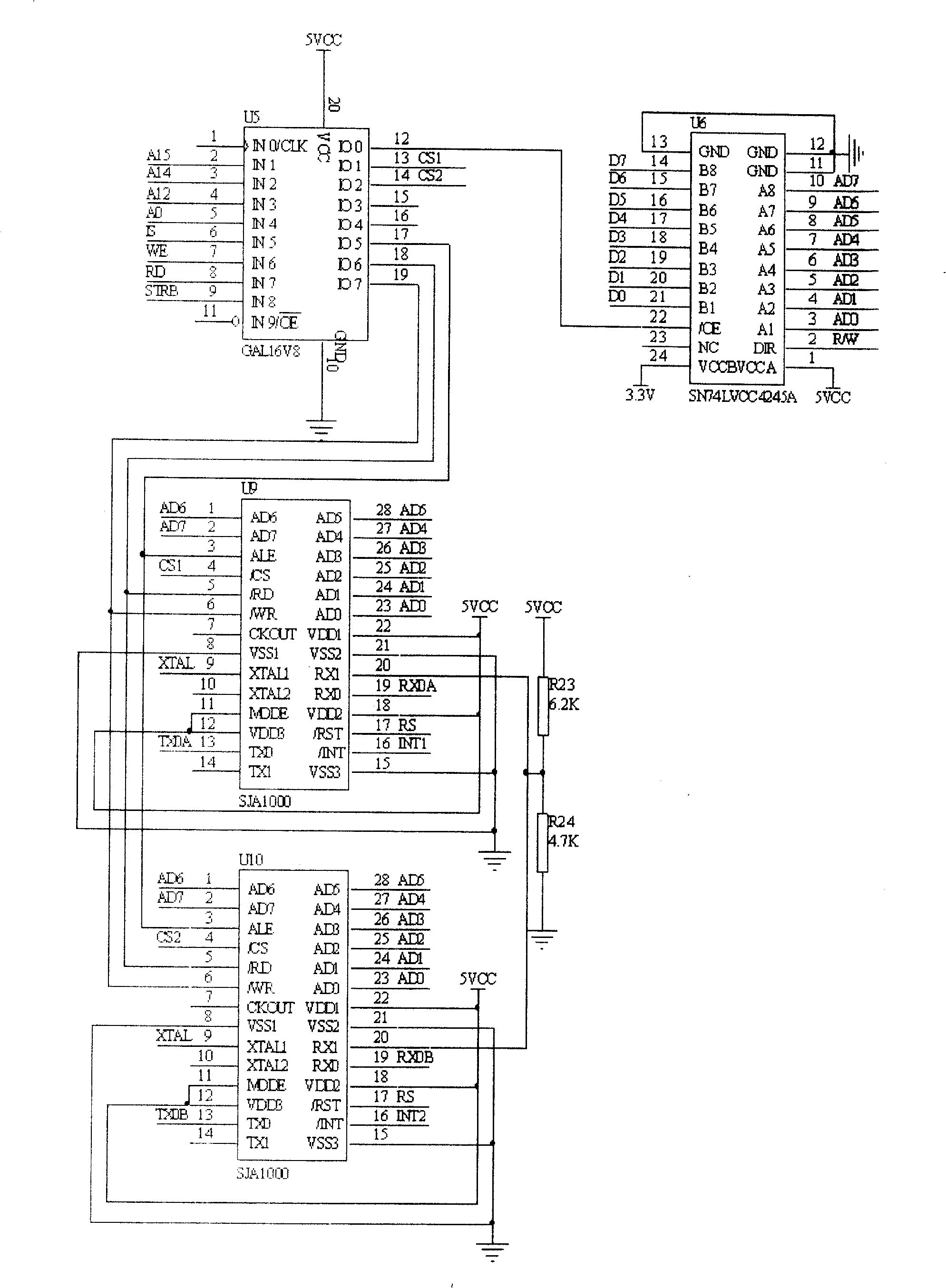

[0040] like Figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com