Mobile device for movable type heavy vehicle lifter

A technology for heavy-duty vehicles and mobile devices, applied in the direction of lifting devices, etc., can solve the problems of heavy-duty vehicles that take a long time and require a lot of manpower and material resources, and achieve the effect of saving time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

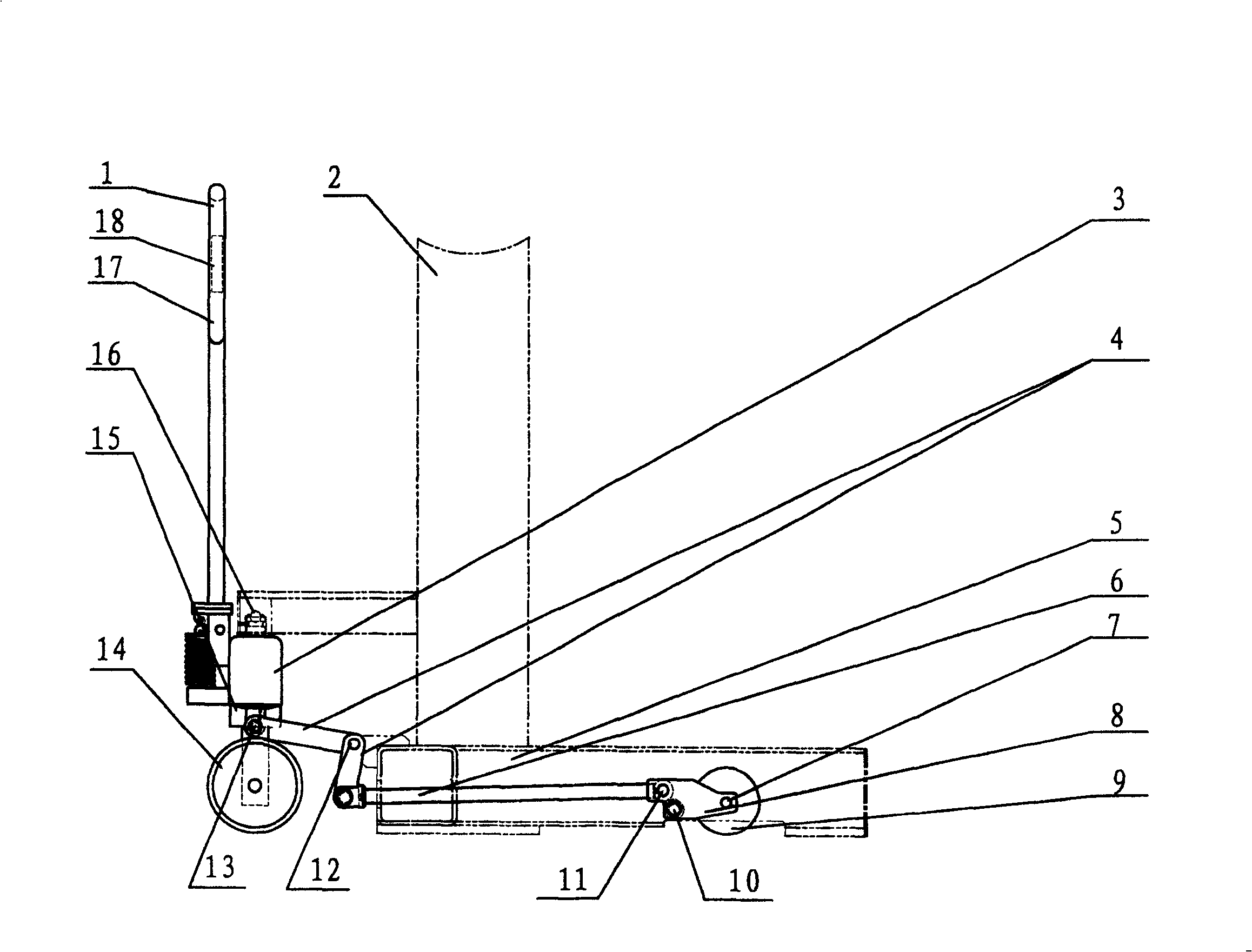

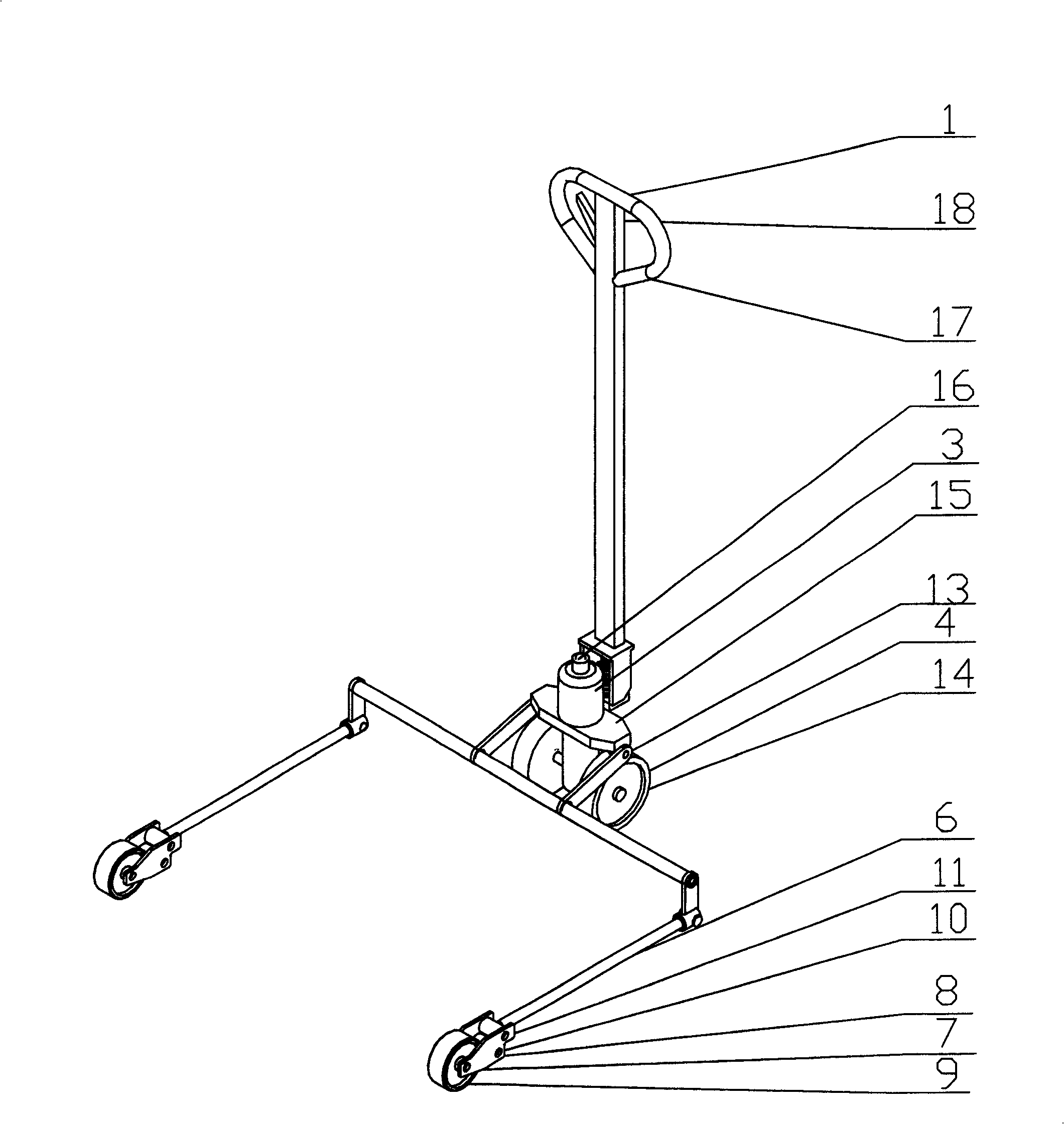

[0013] like figure 1 As shown, a hydraulic forklift 1 with a rear wheel 14 is installed on the rear side of the column 2; two front wheels 9 and connecting rods 6 of the mobile device are respectively installed in two bottom legs 5.

[0014] like figure 2 As shown, an oil cylinder 3 is installed on the hydraulic forklift 1, and the lower end of the oil cylinder 3 is movably connected with the inner end of the crank 4; The outer end of the crank 4 is movably connected, the other end is movably connected with the swing block 8 through the second inner pin shaft 11, the front wheel 9 is movably connected with the swing block 8 through the first inner pin shaft 7, and the swing block 8 is connected with the bottom leg through the outer pin shaft 10. 5 active connections.

[0015] like figure 1 As shown, the upper end of the oil cylinder 3 is movably connected to the welding bracket sleeve of the column 2 through the steel ball 16, and the lower end is movably connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com